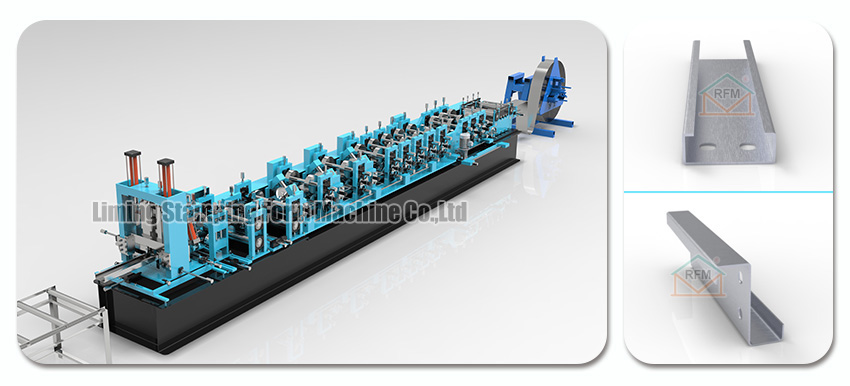

C channel roll forming machine 3mm thickness C/Z/U/L purlin rolling machine

The minimum yield strength of lin strips is about 60% higher than that of hot-rolled steel (that is, angel, trough, square or round hollow profiles usually used for pur strips). In most applications, this high strength-to-weight ratio provides additional spanning capacity for the most cost-effective structure. Ease of handling: The higher strength to lower weight ratio, whether transported to the site or during installation, provides other benefits through easier handling of the lighter parts. Reduce maintenance costs: Surface damage that may be caused during transportation and installation may adversely affect the appearance of the strip. The continuous hot-dip galvanized surface layer is an effective barrier, superior to anti-corrosion coatings in terms of toughness and adhesion. The excellent corrosion resistance of the zinc coating means that potentially high maintenance costs can be avoided. Easy and fast fixing: As the weight of high-strength profiles is thinner and lighter than conventional steel systems, nuts and bolts can be used to reduce fixing time. Additional load-bearing capacity: Due to extensive research on the design, compared with the traditional UI strip system, the purlin rolling machine has better load-bearing capacity and equal load distribution without increasing the total structural weight and load.

Application area Z pur strip can be used for single span in multi-shed construction, non-lap continuous and overlap continuous span. Overlapping continuous spans will cause a significant increase in system capacity.

purlin rolling machine can be used for single span in multi-shed construction, non-overlap continuous span. These types of profiles are very suitable for eaves purlins or where compact profiles are required for detailed design. Sigma lin strips are mainly used in prefabricated building systems.

he metal sheets and metal rods we provide will never compromise.

—CZ purlin roll forming machine—

| No. | Item | Specification |

| 1 | Can Formed Material | GI,AI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 0.3-0.7mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 5500mmx1200mmx1400mm |

| 8 | Speed | 12-15m/min |

| 9 | Diameter of shaft | 40mm |

| 10 | Weight of the Machine | 2200-2500KGS |

—6 major production plants—

—25-36 inspection process—

—Serving 156 countries—

—Multiple national certiffication—

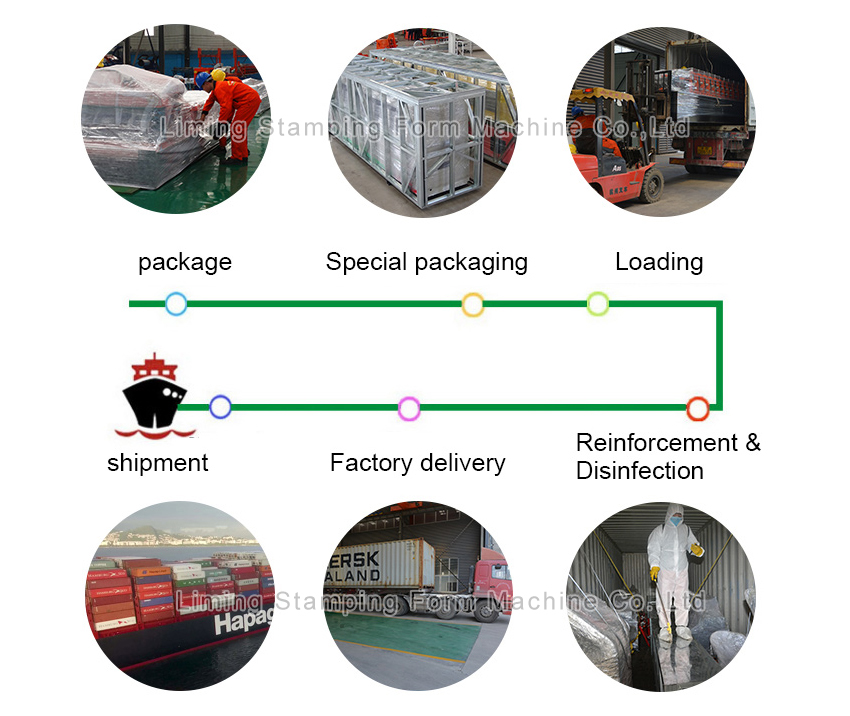

—Product packaging & transportation—