What is the slitting cutting machine ?

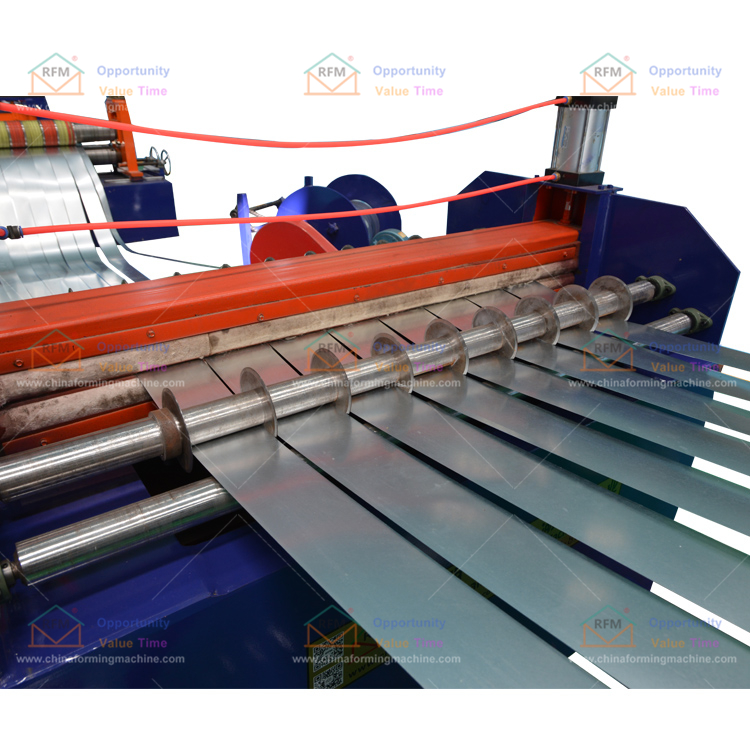

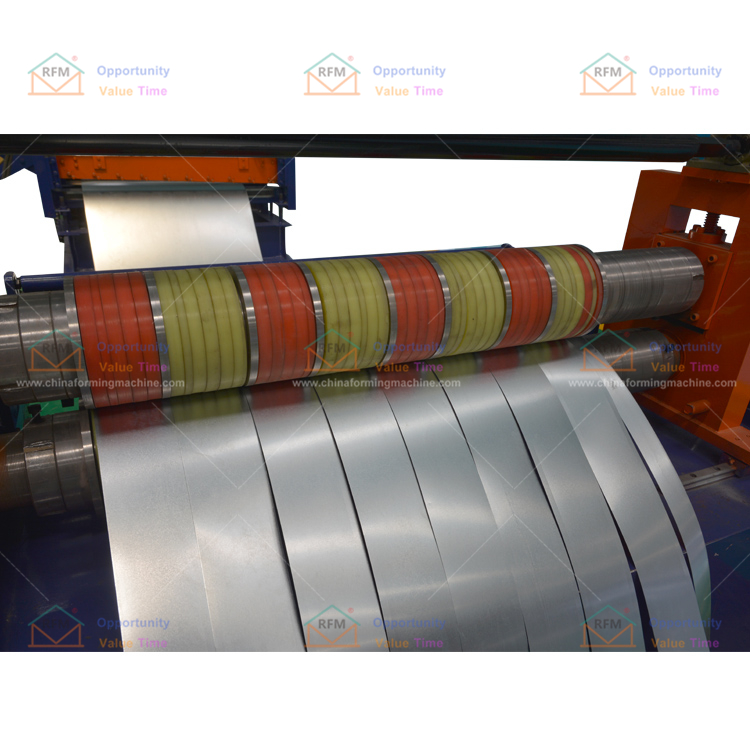

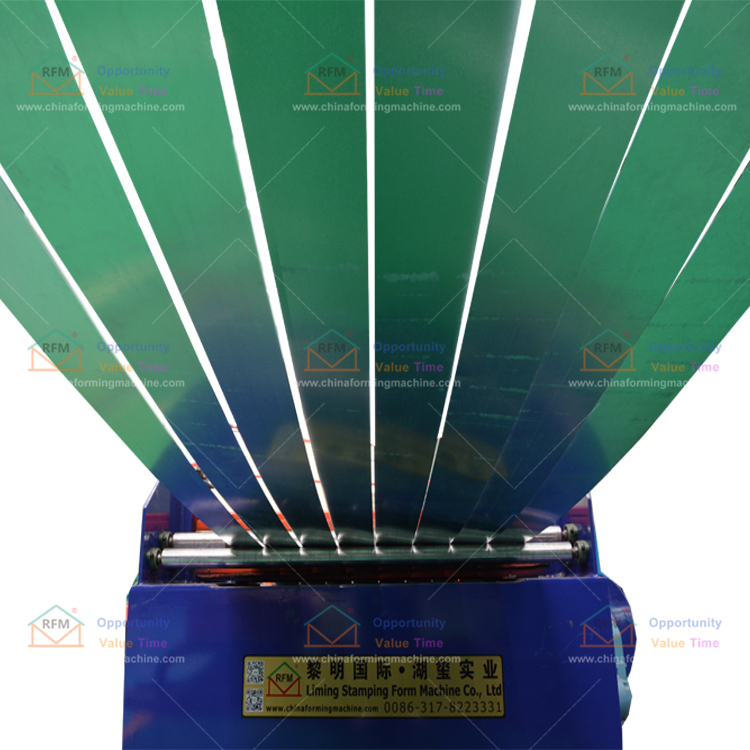

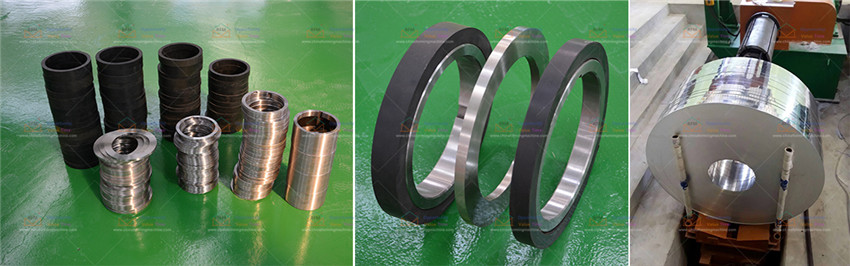

The slitting cutting machine is also called slitting machine and strip cutting machine, which is mainly used for slitting and cutting cold-rolled steel strip, stainless steel strip, aluminum strip, steel strip and other coil materials. It cuts the metal coils into strips of various widths, and then collects the strips into small coils for use in the next process. It is used for precision cutting of profile processing, hardware processing, transformers, motor industries and other metal strips. Required equipment.

table of Contents:

What is slitting cutting machine?

How to judge your industry needs slitting lines

How to reasonably purchase slitting lines according to the workshop area

What kind of raw materials can be cut by the slitting line

Cutting speed of slitting line

When to use the waste collection device

Why is the slitting line digging in the ground?

Parameters: the number of operators, the width of the feed, the maximum thickness, the cutting method, the material of the blade, whether the size can be changed, the error range

Why do you want to add crosscutting

Door-to-door installation and training of the slitting line

How to make a reasonable slitting

What is the difference between a simple slitting machine and a slitting line

What is the working principle of the compression device

The maximum weight that can be placed on the coil

27 year production of slitting cutting machine manufacturer

We will provide you with a slitting cutting machine based on your material and thickness

Provide Installation Method & Customized Profile For Free

slitting cutting machine

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

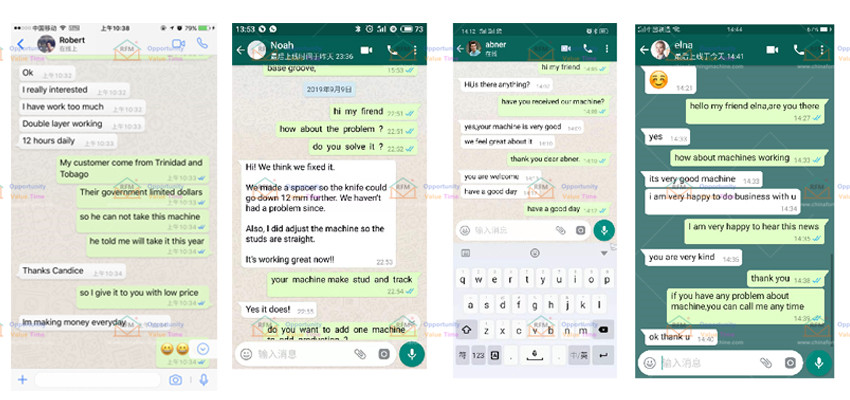

Customer Feedback

FAQ

Q1. How do I choose the right machine for me?

1. A machine doesn’t just provide a few photos to prove what they can produce

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You don’t show the product I need, can you manufacture it?

Our company’s engineers have studied in well-known European cold bending companies and have great advantages in machine design and R&D and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 40 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate, and have a longer service life.

The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, 26 years of production experience, to be a service company that you have the strength to guarantee

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don’t have your own outline drawing, we can recommend some models according to your local market standard.

For more great product videos visit our YouTube