How the stable galvanized steel drop ceiling wall angle roll forming machine base ensure the manufacturer precision?

The below will introduce the drop ceiling wall angle roll forming machine processing, and the reasons why it can ensure the production precision.

The machine base is the first module part of the equipment. On top of it there be the other three large modules, which are the roller stand, roller shaft and the rollers. Because it is the equipment base, which is important part, so we purchased the heavy steel raw materials from state-owned steel mills with CE and ISO certified. Also the solid base can solve the problem that machine frame deformation and re-debug caused by the un flat site and or the factory future expand relocation, and can ensure that after finish power connection, the machine can be produced within 24 hours,About the machine base processing, our company have a 10-meteer large-scale Japanese FANUC system CNC Milling machine, including fully automatic positioning and punching function. This is currently only available to us in the industry. It has innovated 99% of factories in the industry to entrust third-party processing or domestic brand machine tools to produce: A plane roughness is too large. B the old process of manual measurement and drilling, all the problems will lead to the profile deviation problem. The reliable raw materials plus the CNC accuracy processing and punching process of Japan, can make the wall angle roll forming machine base are stable and production accurate as your business.

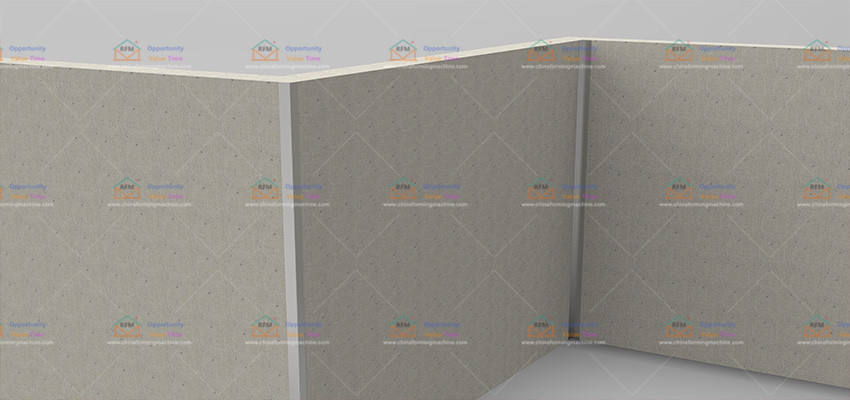

Wall angle roll forming machine Application Range & Scene

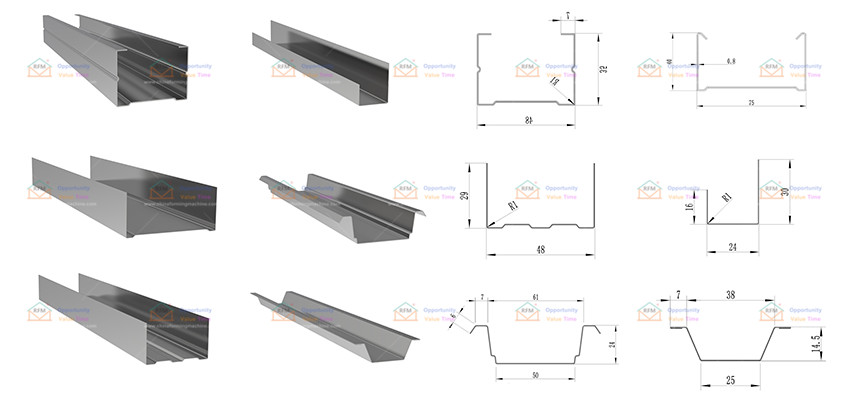

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects Of Wall angle

Inspection/Package/Delivery

Customer Feedback