Hot sale customized design roof veneer roll forming machine

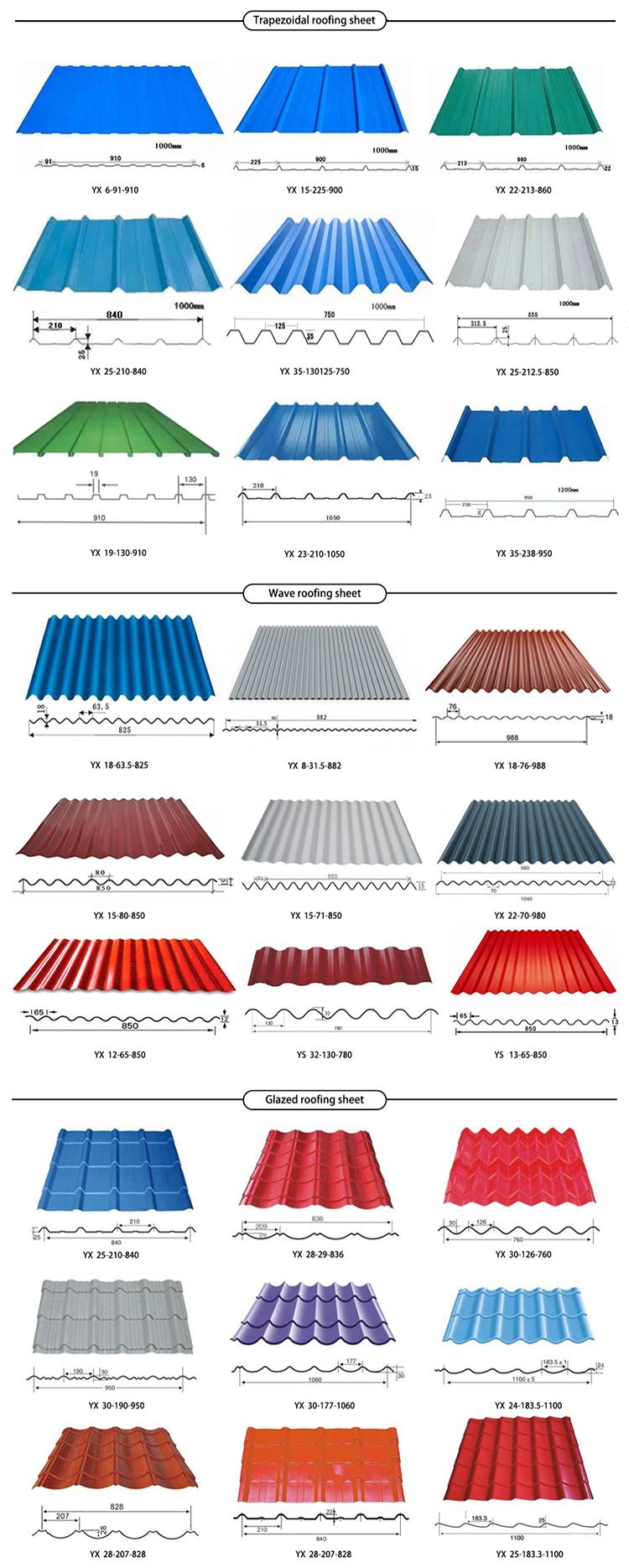

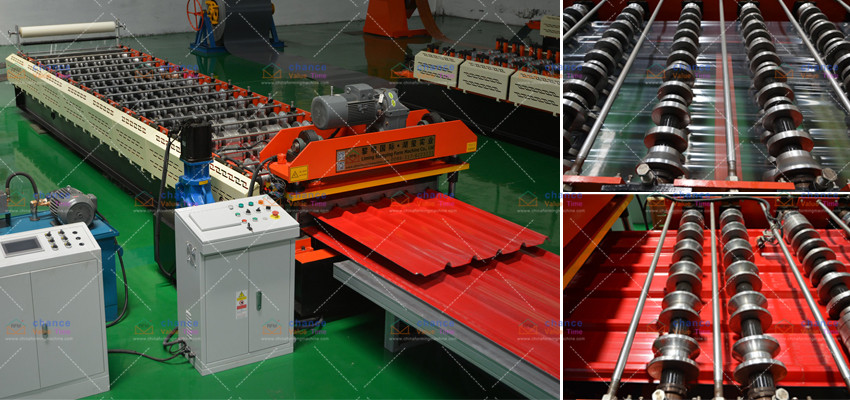

Mr. Sajeesh is one of my customers from Saudi Arabia, he is a procurement engineer. Mr. Sajeesh’s company wants to invest in a factory in Jeddah. The management of the company considered the space cost and wanted to order a double-layer machine to produce corrugated and trapezoidal plates. Mr. Sajeesh found our company. After I understood Mr. Harry’s ideas, I made a two-set plan for him. One solution is a two-layer machine. The two-layer machine can indeed save space, but there are also limitations on output. First of all, when the double-layer machine produces one pattern, it cannot produce another pattern. Secondly, the speed of the double-layer machine cannot be too fast, otherwise the machine will be unstable. Since Mr. Sajeesh’s company has huge requirements for veneer output, I recommended two of our high-speed 60m/min color steel tile roll forming machines for the second set of plans. This high-speed machine is for companies with large sales. The machine cost can be recovered quickly, which is very suitable for Mr. Sajeesh’s company. We also provided Mr. Sajeesh with our automatic decoiler and automatic stacker, which can effectively save labor costs. We can provide the function of veneer coating, and we also gifted his machine’s exclusive documents. From the exclusive machine file, guests can know any part of the machine. Can know how to operate the machine and how to maintain it. After receiving the plan, Mr. Sajeesh carefully submitted the plan to the management of the company and was approved by the management.