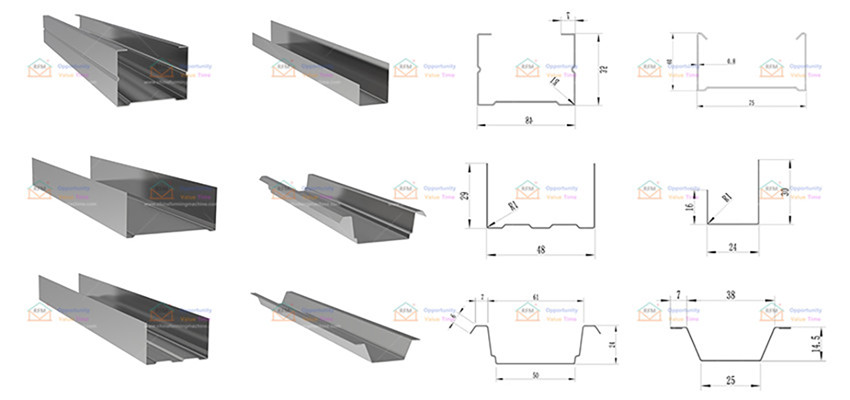

During the online exhibition, an Indonesian customer had a one-to-one communication with us online and learned about our high-quality ceiling U-shaped keel forming equipment. With more than 24 years of manufacturing experience, professional knowledge and excellent human resources, our U-shaped keel forming equipment can produce two types of ceiling keels: medium and small keels are closely attached to the large keel, and the bottom is suspended (that is, not the same Horizontal plane) is called a double-layer structure; the bottom surfaces of large and medium keels are on the same level, or the middle keel is directly hung without a large keel, it is called a single-layer structure. The latter is only used for light ceilings. We provide customers with high-quality U-shaped keel machines suitable for roof decorations of various buildings, internal and external walls of buildings and scaffolding ceilings. The width, height, and steel plate thickness of the keel section shape are based on customer production requirements. The professional design team uses well-known design software: German Kopra, Vertex BD to design high-quality production equipment. In addition, all the parts and components on the equipment come from first-line brands at home and abroad, which are high-quality products certified by ISO and CE. The equipment operating system adopts a well-known international operating system, which can be selected according to the user’s local language, and customized operating settings can be used to achieve a strong combination of hardware and software to enhance the good experience of use and operation.

During this process, the customer further understood the composition of our production equipment. Our machine is equipped with a heavy-duty reducer, which provides a powerful transmission system for production and transmission. At the same time, the equipment is equipped with the same process of imported CNC machine tools, using the industry’s thickest 2mm paint process to achieve a 180° transmission protection system to ensure production safety. The electrical components of the electronic control system of all equipment are 100% authentic and assembled by themselves. They can be imported from Germany’s Siemens, Schneider, Japan’s Mitsubishi, Panasonic and Taiwan and other top international brands, which are easy to maintain and guarantee 24-hour uninterrupted mass production to create more value. Through professional explanations, customer is very interested in our machinery and equipment and express his strong desire for further cooperation!

U-shaped keel forming equipment Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery