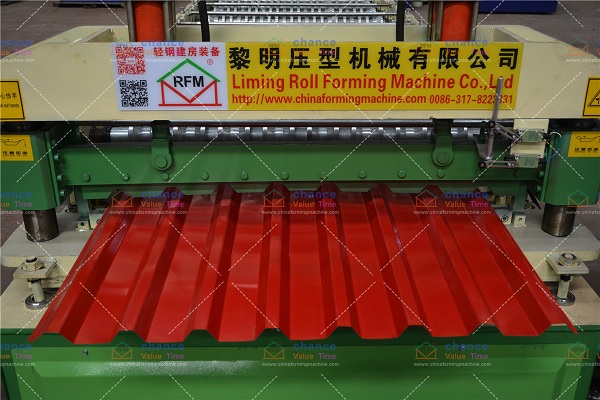

The working principle of color steel tile pressing machine

The worktable of the color steel tile pressing machine has six processes (ie, the hexagonal runner). In addition to the first-level mechanical indexing and positioning, there is also a set of precision positioning mechanisms to fully ensure that each stamping process, The accurate positioning of the workbench mold, the slide table on which the upper mold is installed is a box structure, the slide rail and the upper rail of the fuselage have a large contact length, and each time the upper mold is stamped, the process has a second stamping on the mud billet, that is, the upper mold. After starting to press the tile blank in place, the upper die rises 10㎜. Cold-formed steel is the main material for making light-weight steel structures. It is made by cold bending of steel plates or steel strips.

C-type steel machine manufacturing its wall thickness can be made very thin, and greatly simplifies the production process and improve production efficiency. It can produce all kinds of profiles with uniform wall thickness and complex cross-section shapes that are difficult to produce by the general hot rolling method and cold-formed color steel equipment of different materials. After the mud billet is fully exhausted, the upper die presses the tile billet down into place before returning to the high position, so the die has a long service life and the quality of the pressed product is good.

The color steel tile press machine will be equipped with a set of lubrication system. When the machine is running, it will automatically lubricate all bearing bearings and the motion guide rails of the transmission gear mechanism.