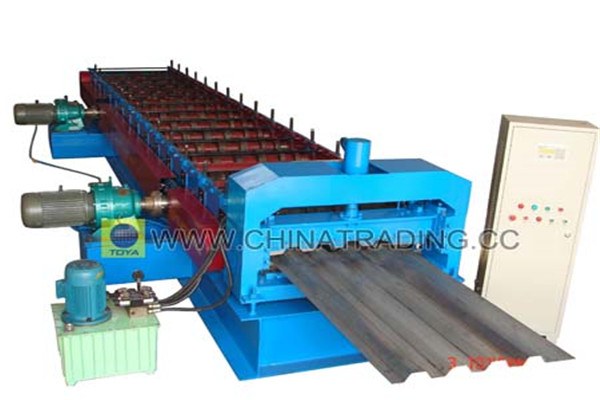

The Container Board Roll Forming Machine

Container

board roll forming machine configuration is as follows:

Work

flow: (send wool blank) Uncoiled – guided feed – roll forming – fixed length

cut off – finished out of the board

Manually

set the workpiece, manual roll, enter the PLC operation page – press the

“start” button – automatically enter the plate – start by the set

procedures – to set the size of the self-cut, the device automatically The

press plate is finished.

Dimensions:

7.8 * 1.5 * 1.2m

Motor

power: 11Kw Operating voltage 380V

Production

speed: 5-8 m / min (without cutting time)

Pressure

shaft diameter: 13 Road

Shaft

diameter: 95mm solid shaft Material: 45 # steel quenched and tempered

Pressure

wheel: 45 # forgings, fine cars, polished, hard chrome plated surface

Equipment

chassis: 350H steel 16mm thick plate

Transmission:

2-inch chain drive

Cutting

machine power: 7.5Kw pumping station, cutting equipment

Cutter:

Cr12 material, made by high temperature vacuum quenching, composed of two

knives

Molding

part: roll forming system consists of rack, transmission parts and cold forming

roller group and so on. Divided into Seiko wheel rotation molding, forming

effect is good, reduce the wheel and the friction between the raw materials,

debugging convenient, fast.

Pls

contact with me if you want it.

Liming

Stamping Form Machine Co.,Ltd

Address:No

3 Road, Industrial Development Zone, Botou City,Hebei Province, China

Wechat/Whatsapp:+86-18831701987 TEL:0086-317-8223331

QQ:

2880998756 SKPYE: limingywj008

Trademanger:

cn200079653

http://www.chinaformingmachine.com

Email:

liming1@chinaformingmachine.com