Talk about C-shaped steel machine in detail

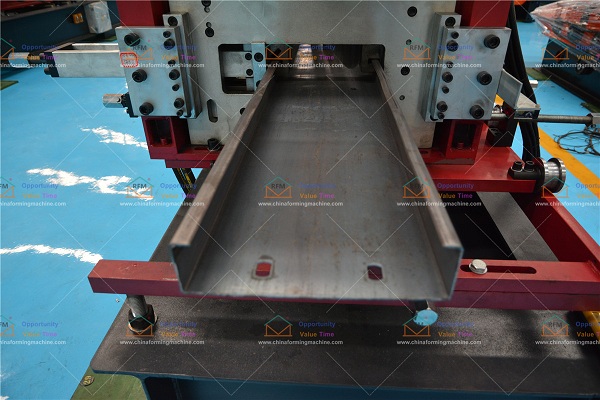

C-shaped steel equipment is a set of single-roll forming unit whose rolls can produce various specifications of C-shaped purlins. The C-shaped steel equipment is mainly composed of passive loading rack, leveling device, punching device, cutting device after forming, hydraulic station, computer control system, etc. This machine adopts automatic flying saw punching, easy operation and other characteristics.

The C-shaped steel products rolled by the C-shaped steel equipment have good tensile and bending performance, good straightness, automatic fixed-length cutting, automatic punching, high degree of automation, fast and convenient installation, and the product can be used as the main body of large and medium-sized industrial civil buildings. Force structures, such as roof load-bearing load and flat wall support of factory buildings, warehouses, hangars, hangars, exhibition halls, theaters, stadiums, and market sheds.

Cold-formed steel is the main material for making light-weight steel structures. It is made by cold bending of steel plates or steel strips. The wall thickness of the C-shaped steel machine can be made very thin, and the production process is greatly simplified and the production efficiency is improved. It can produce all kinds of profiles with different wall thickness and complex cross-section shapes that are difficult to produce by the general hot rolling method and cold-formed steel with different materials.

C-shaped steel machine is a set of single-roll forming unit whose roll can produce various specifications of C-shaped purlin finished products. This machine is mainly composed of passive loading rack, leveling device, punching device, cutting device after forming, hydraulic station, computer control system, etc.