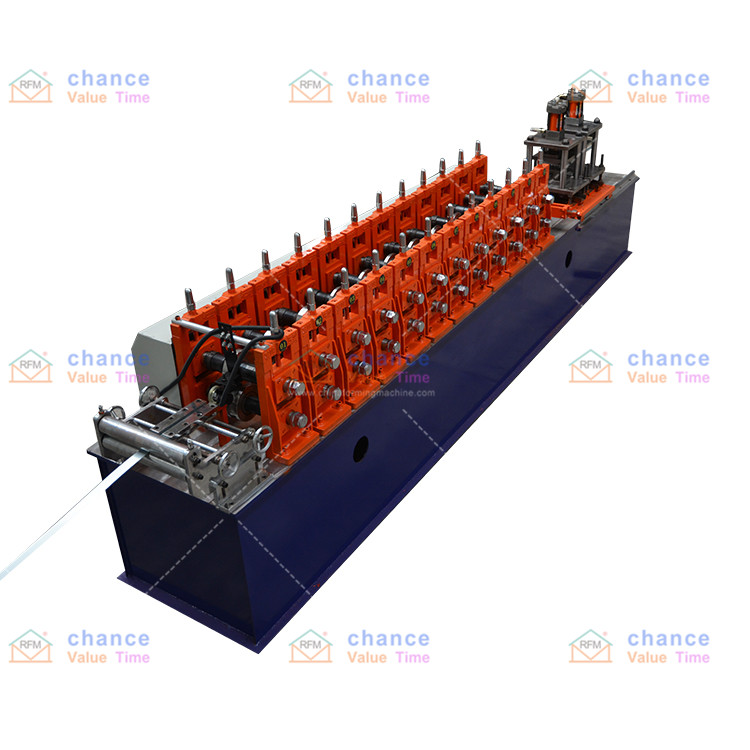

Automatic New Technology Metal Stud And Track Roll Forming Machine

How the stud and track roll forming machine roller affect the product precision?

The roller is the key part of a roll forming machine, if the roller can not ensure design and processed precision, it will affect the final stud and track product produced deformation, and also need high machine maintenance such as the frequency debugging. So below will introduce that what things we do to keep the roller quality and product produced precision.

The mold wheel is the most used part of the galvanized steel stud track roll forming machine. First the raw materials we using which is real CR12 from the CE and ISO certified state-owned steel mills, so it can solve the unstable material of different batches of non-state-owned small factories and errors caused by roller breakage and wear during production, ensure that the machine is uninterrupted for 24 hours, and create money every minute when it is turned on, our processing profiles roller designed by Copra in Germany, have past many times calculate and analysis the roll forming steps, it will ensure the roller design precision and about the processing, we do the strictly quench processing, can ensure the appearance is smooth, will not have scratches, so finally can make the drywall usage galvanized steel stud track roll forming machine production precision.

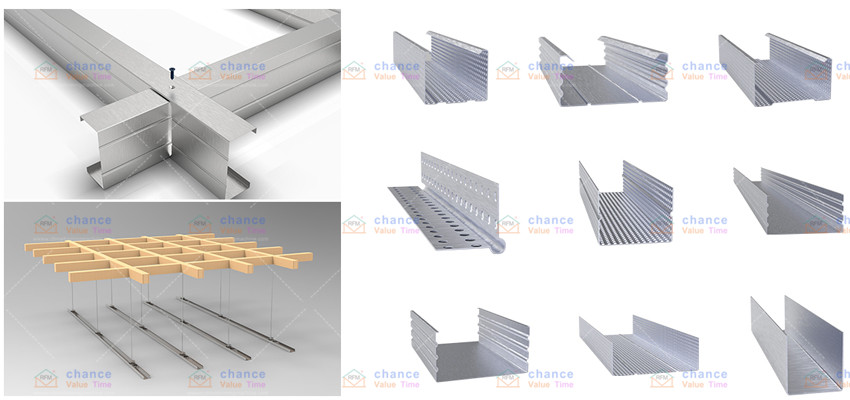

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

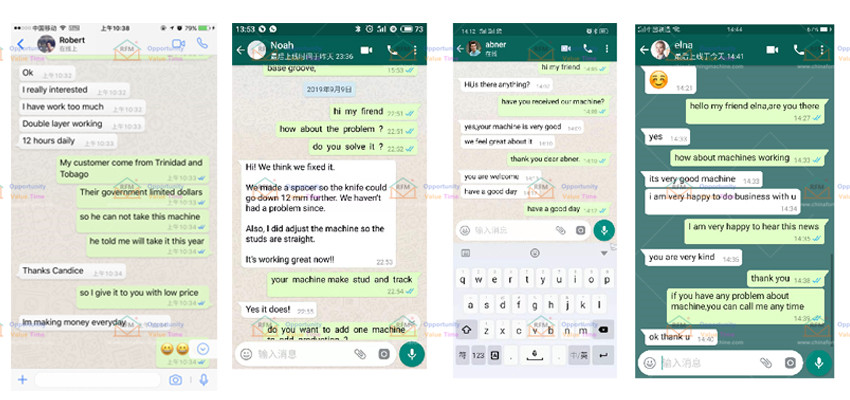

Customer Feedback

FAQ

Q1. How do I choose the right machine for me?

1. A machine doesn’t just provide a few photos to prove what they can produce

2. A machine should have a complete production and assembly system photos and videos.

When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You don’t show the product I need, can you manufacture it?

Our company’s engineers have studied in well-known European cold bending companies and have great advantages in machine design and R&D and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 40 days to complete, if you need a machine urgently,

we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated,

more reliable and accurate, and have a longer service life.

The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, 26 years of production experience,

to be a service company that you have the strength to guarantee

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don’t have your own outline drawing, we can recommend some models according to your local market standard.