According to the needs of different customers for different output, our engineers have carried out technical research and development on speed improvement. Use professional data software for calculation, combined with years of manufacturing experience of professional engineers. Under the premise of not affecting the quality of the final product, adjust the power system and spare parts and update the production technology to meet the needs of different production speeds

And after our machine is completed, we will check the status of the product produced by the machine, and immediately adjust the structure of the machine if there is a burr or distortion. After many debugging and inspections, we ensure that the final product produced by our machine can reach the best condition before leaving the factory, and we shoot a video for the husband, let him personally watch the product surface, section and other details to ensure that the customer is satisfied with the machine Will leave the factory.

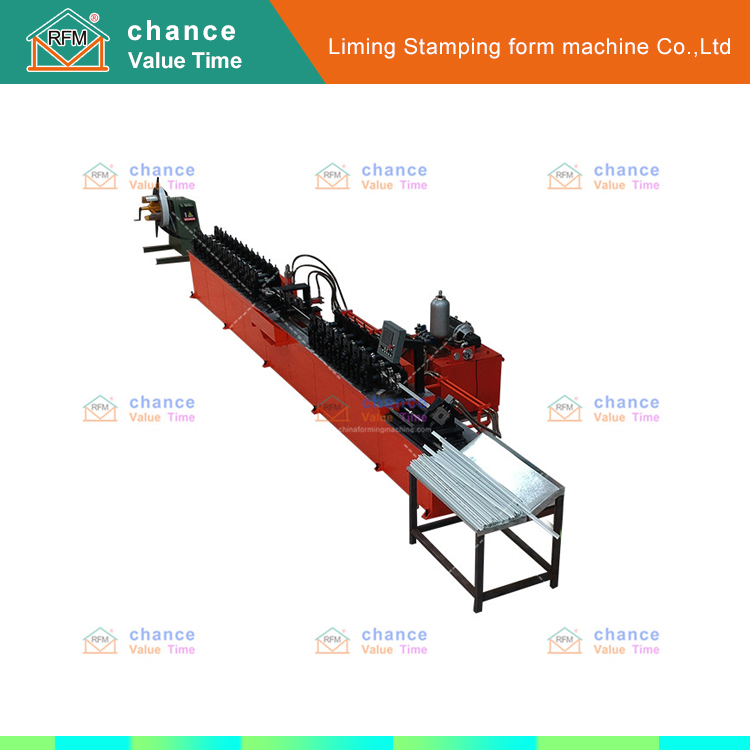

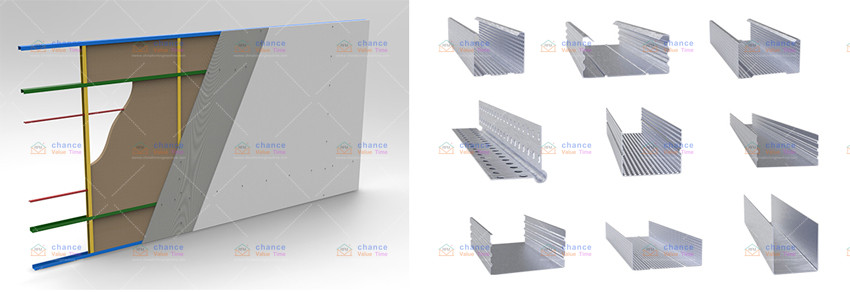

Application Range & Scene Stud keel roll forming machine

Provide Installation Method & Customized Profile For Free

Stud keel roll forming machine professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

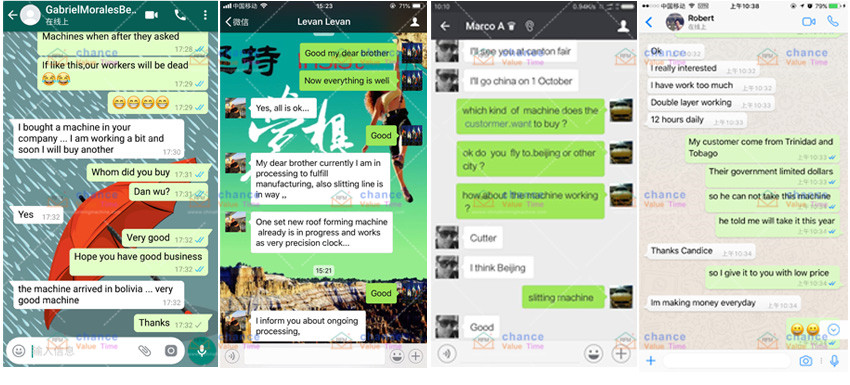

Customer Feedback