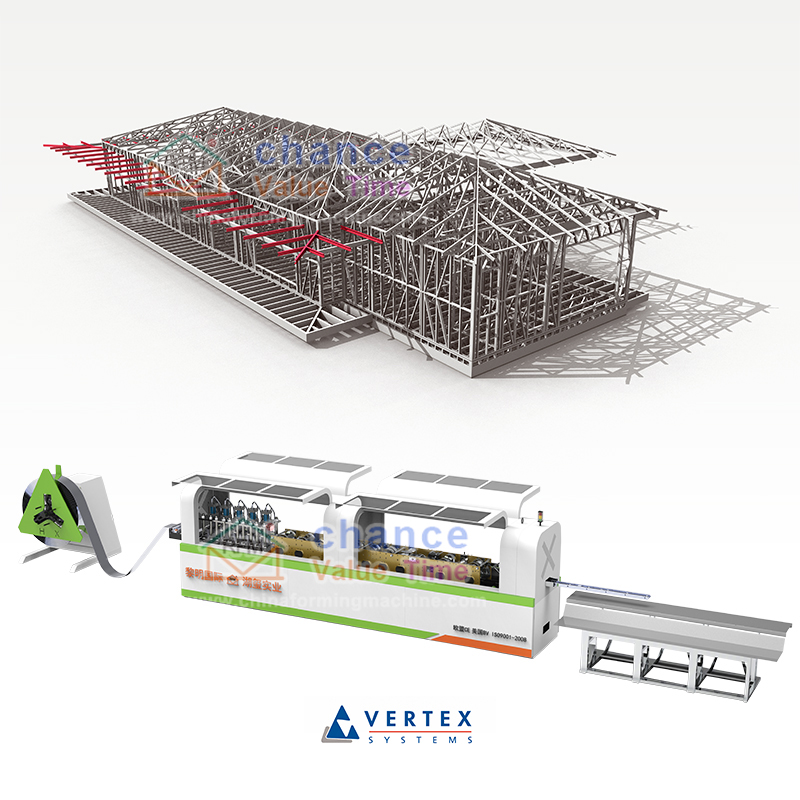

Light Gauge Steel Framing Machine manufacturer in china

Light Gauge Steel Framing Machine uses strip steel as raw material to produce complex cross-section contours and cold bending of different specifications through continuous cold rolling, which is controlled by PLC.

They are assembled into light steel houses. The machines are suitable for light steel house projects. Our machines are exported to Southeast Asia, Ukraine, Russia, Saudi Arabia, Dubai and other countries.

Video of Light Gauge Steel Framing Machine

If you are inconvenient to come to visit, please click here(VR Video Factory Audit)

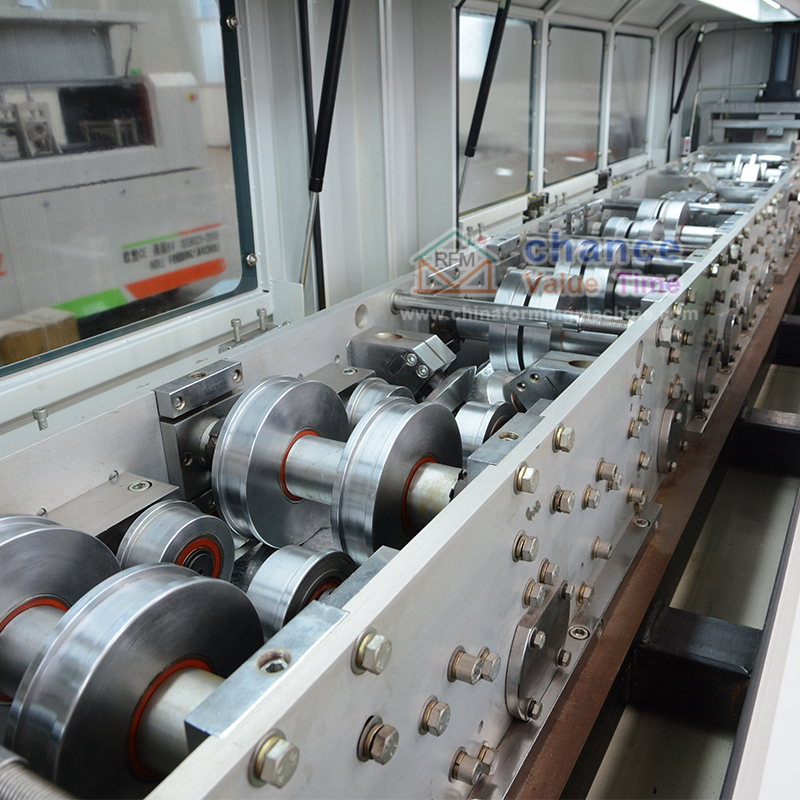

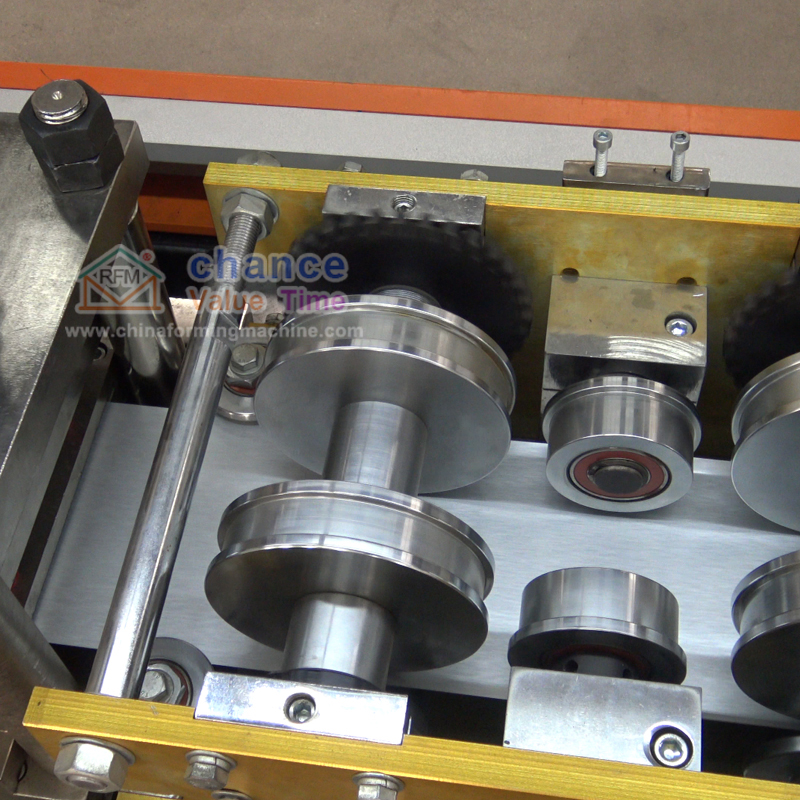

The machine structure of Light Gauge Steel Framing Machine:

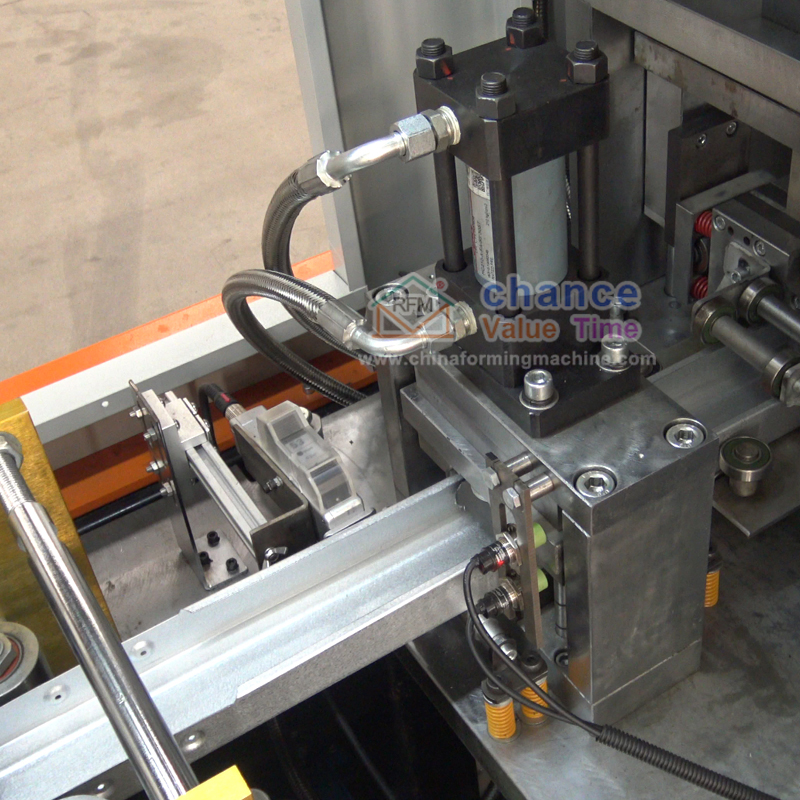

1. Steel Framing Machine Hydraulic system: In this machine, the most powerful is the oil pump. Our oil pump adopts the oil pump of the Japanese Yuken brand. It is installed on the lower level of the mailbox and pumps hydraulic oil cyclically to provide all the hydraulic devices of the whole machine. power. Equivalent to the human heart, Japan Yuken is the largest hydraulic manufacturer in Japan, providing high-quality hydraulic components for global machinery and equipment.

In our upgrade and testing of machinery, the designer tested 5 brands in total, and the 5 powers are basically the same. , But the Japanese oil salt is the most stable and smoothest power output. The important thing is that the oil and salt brand has distributors all over the world. If it fails, you can quickly buy and replace it. Thanks for the after-sales service of this brand.

2. Steel Framing Machine Encoder: 80% of Liming’s cold-formed machinery is made of Japanese Omron, which is generally located at the front end of the entire machine, including the code register and the code roller. And this mechanical code counter adopts the German brand ~ Kübler, and is equipped with a high-strength buffer spring with shock absorber function, and is equipped with a technical code wheel that prevents slippage. The code wheel is hardened and has a service life of at least 2 years.

3. Print cartridges: Each profile will have a corresponding clear number, like Lego to assemble the house frame, the inkjet must be quick-drying and durable. In order to match the higher production speed, the cartridges are made of HP brand. In addition, the number of prints that have been printed, the number of remaining prints, and the percentage of remaining ink are displayed on the coding system. The operator can prepare replacements in advance. So as not to delay production. Consumables can be purchased worldwide.

4. PLC control system: Our PLC uses the German Siemens brand, and the rest of the electronic components are all French Schneider. The purpose of this is that if some electronic components are damaged in the later stage, you can easily buy replacement parts, so as not to delay your production.

If you want to know more about the professional knowledge of Light Gauge Steel Framing Machine, welcome to consult. I will provide you with professional services.