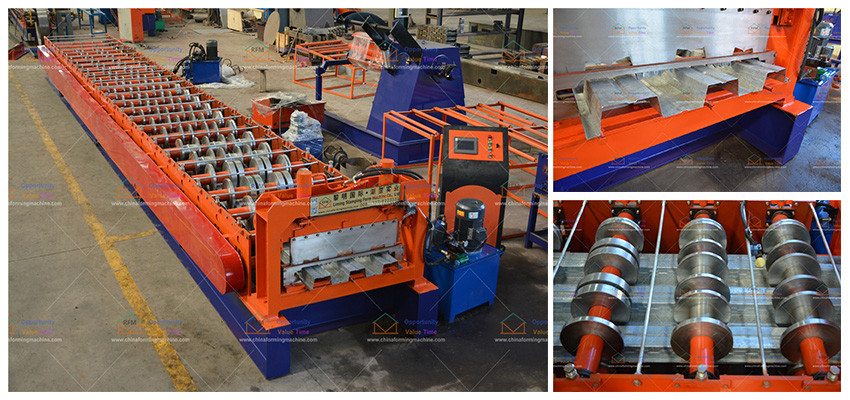

The importance of the correct operation of the Steel Floor Decking Plate Roll Forming Machine, the floor deck equipment not only needs to be used but also can be maintained. Proper maintenance methods can extend the life of the tile press equipment. Usually, in the process of use, we should pay attention to the operation process of this convenient Steel Floor Decking Plate Roll Forming Machine to see if it is the same as the previous operation and whether there are any differences. If so, we must check what it is. Reasons, so as to solve the problems in time.

We need to frequently check whether each part is stable, and clean each part frequently, especially the fuel tank and oil filtering equipment, to keep the oil pipe smooth.

For the hydraulic oil floor deck equipment, we must replace it regularly. When replacing, check and clean the oil tank, oil pipe and other oil circuits. If there is foreign matter in the hydraulic oil, it will cause the hydraulic system to be abnormal and increase the operating time of the oil pump, cylinder, reversing valve, etc. Therefore, we need to always pay attention to the use process of the Steel Floor Decking Plate Roll Forming Machine for the construction of the construction team.

During the use of floor deck equipment, we must pay attention to the operation of the floor deck equipment, and solve the problem when we find the problem. Don’t think that the problem is small and not solve it. Sometimes small problems can lead to major failures. For the maintenance of the tile press, a plan should be made to achieve regular maintenance. The maintenance of the tile press has played a great role in prolonging the life of the tile press. Users of tile press must not underestimate the importance of tile press maintenance. The worktable of the color steel tile press has six processes. The turning of the worktable, in addition to mechanical indexing and positioning, is also equipped with a set of positioning mechanism, that is, the correct positioning of the worktable mold during each stamping process and the installation of the upper mold The sliding table is a box structure. The sliding table guide rail and the upper guide rail of the fuselage have a large contact length. Each time the upper mold is punched, the process has a secondary stamping of the mud blank, that is, the upper mold. After rising 10mm to fully exhaust the mud, the upper mold presses the tile down in place before returning to the highest position, so the mold has a long service life and the quality of the pressed product is good. The 840 color steel tile press is a hydraulic press used to shape and press the rough tile blanks extruded and cut by the vacuum screw extruder when producing glazed tiles. The automatic tile press can be installed and used separately, but it needs to be manually loaded and unloaded. It can also be equipped with an automatic loading rack and unloading manipulator, an extruder, a tile cutter, a blank feeder, and a wato conveyor line to form tile blanks. The production line does not require manual manipulation.

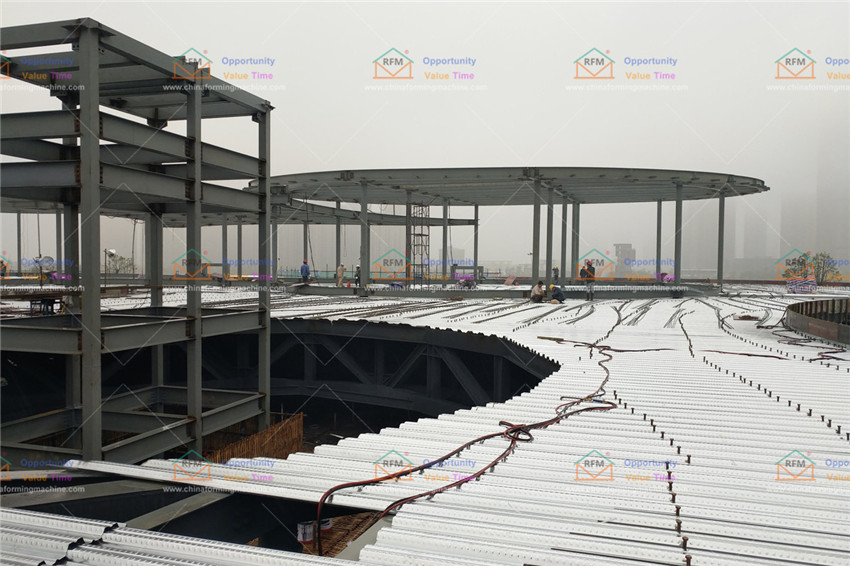

Application Range & Scene

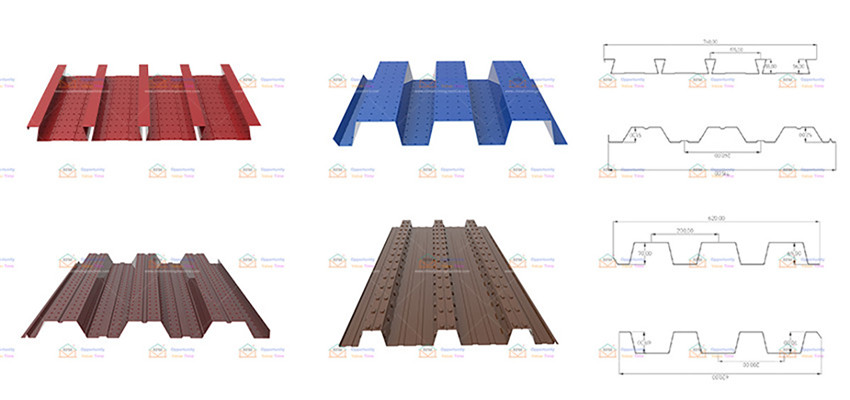

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

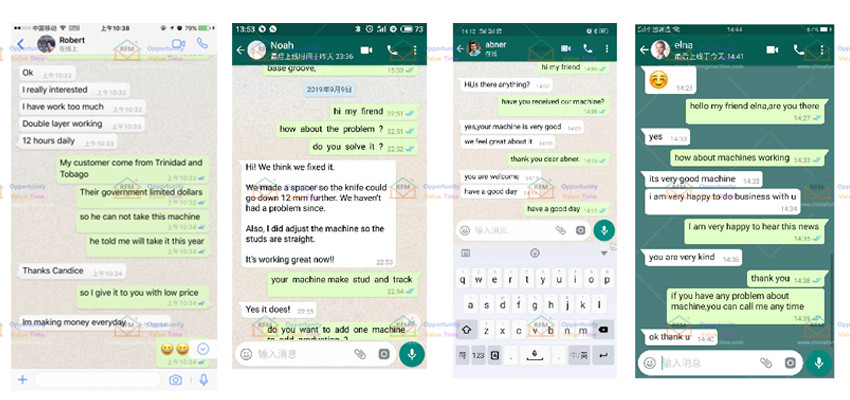

Customer Feedback