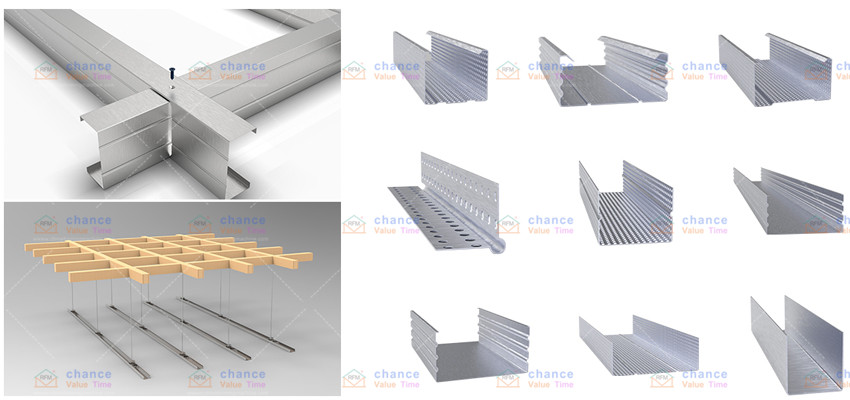

Liming Company drywall Profile Forming Machine is designed to produce non load-bearing partitions in galvanized steel. It has a wide range of applications, from small and residential needs to large commercial and industrial applications. Using start-stop technology, these machines can make 8 profiles that make up all the basic metal frames for plasterboard walls and ceilings: three different with supporting stud and track, a ceiling profile and the relative wall angle. Drywall Profile Forming Machines offer high performance, low cost and long lifetime.

Operation and Maintenance: 1. Uncoiler: Mechanical uncoiling, can be adjusted to different coiler’s radius. Capacity up to 5 ton; 2. Automation System: The electric panel is easy to operate and offers the option of manual-automatic work. With the MMI (Man Machine Interface), it allows the operator to do three different programming at a time. 3. Roll set: Built in Cr12 – conferring larger durability and greater wear resistance to the rolls and optimal shape to the product. The transmission is made through chains and a 4HP motor power. Regular lubrication is required; 4. Cutting System: Automatic cutting system by hydraulic guillotine (4HP). The cutter follows perfectly the related shape, ensuring excellent finish to the workpiece;

Application Range & Scene Steel drywall profile roll forming machine

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

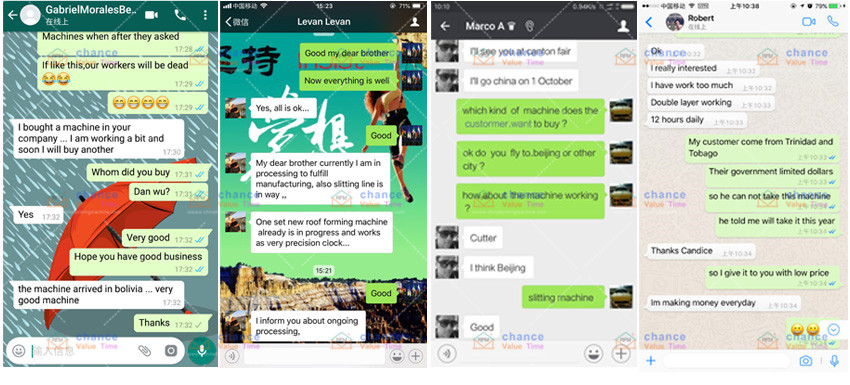

Customer Feedback