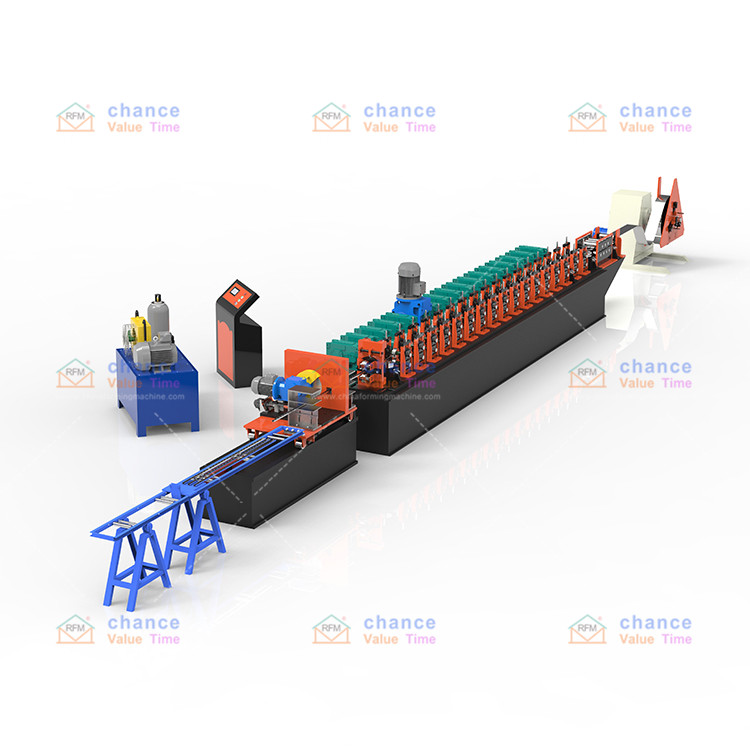

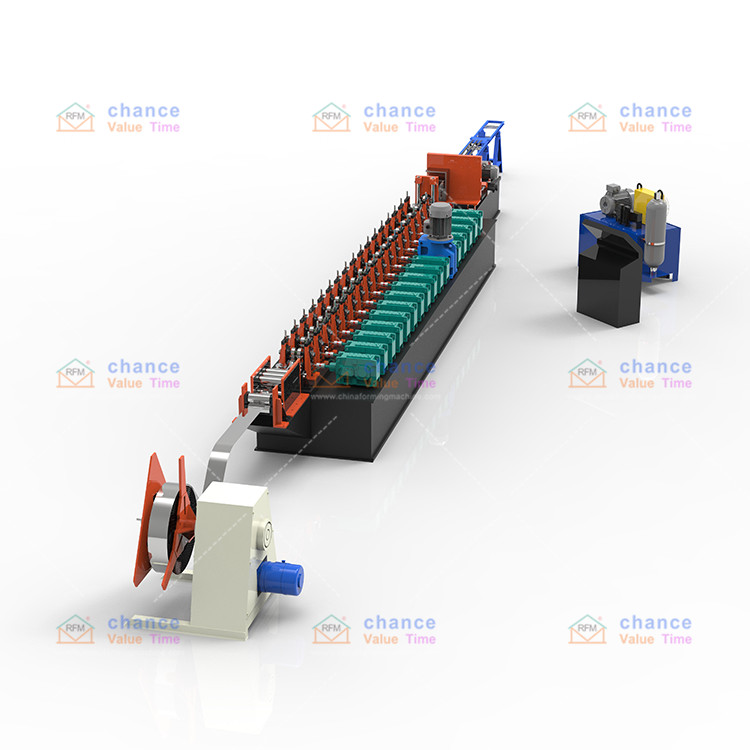

C Channel Photovoltaic Stent Solar Bracket Roll Forming Machine

Click to watch the video

The global energy crisis has promoted the rapid development of the new energy industry, and solar energy is the most important basic energy source among all kinds of renewable energy; therefore, as a solar power technology that converts solar radiant energy into electrical energy, the photovoltaic industry is developing even more. Fast; In the old concept, the photovoltaic industry mainly includes the production chain of solar modules, and the production chain of electrical control components such as controllers and inverters.

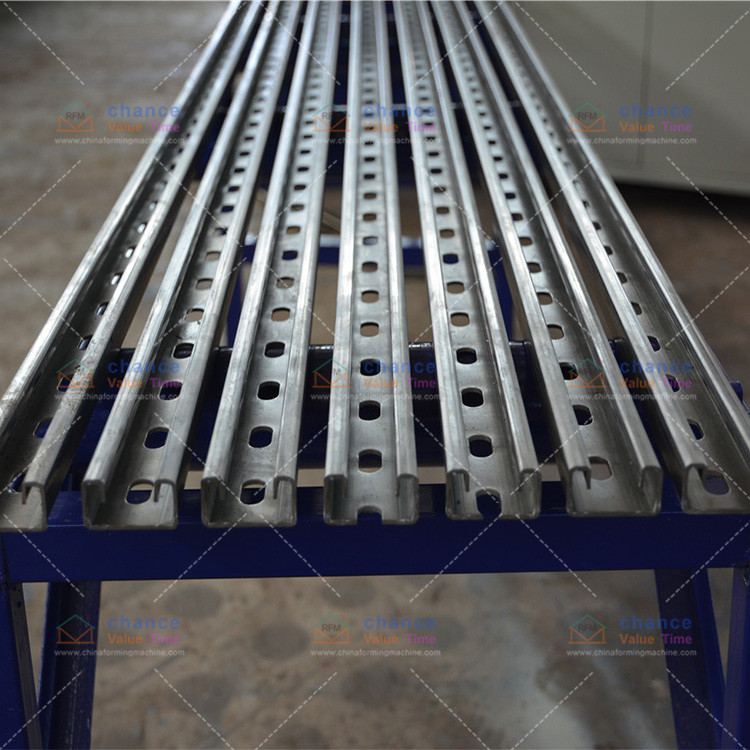

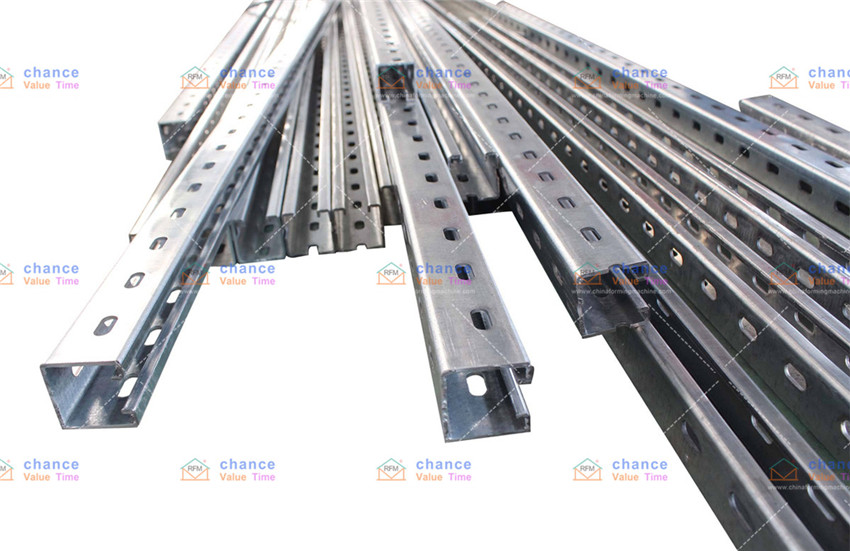

The application advantages of solar support system in solar panel support are far more than simple production and installation. Solar panels can also move flexibly according to the sun’s rays and seasons. Just like when it was just installed, the inclined surface of each solar panel can be adjusted to adapt to different angles of light by moving the fasteners, and the solar panel can be accurately fixed at the designated position by tightening it again.

In order to solve the problem of low production efficiency of photovoltaic brackets, LIMING has developed a rotary punching + Solar Bracket Roll Forming Machine. The production speed can be adjusted, and the maximum speed can reach 100m/min.

During this period, Sungevity, a solar energy contracting company in the United States, consulted me for details of the high-speed sSolar Bracket Roll Forming Machine.

During our communication, we learned that the machines used by their company are slow in production speed, prone to failures, and high maintenance costs.

When there are projects, they cannot complete orders quickly; many large orders have been lost.

Therefore, I recommend our cost-effective Solar Bracket Roll Forming Machine to better meet customer needs.

This kind of Solar Bracket Roll Forming Machine with high-speed production can be used to produce heavy-duty load-bearing frames, and the supporting force makes the entire solar photovoltaic panel more stable.

LIMING has developed a high-speed punching device, combined with a high-speed Solar Bracket Roll Forming Machine, to increase the customer’s output several times

Click to consult the high-speed punching video

The Solar Bracket Roll Forming Machine provided by LIMING has multiple solutions for you to choose:

1. We directly provide high-speed punching services. You can choose to directly purchase our raw materials with holes and use your Solar Bracket Roll Forming Machine to produce them.

2. Purchasing punched raw materials in your country, we sell high-speed 30-80m/min Solar Bracket Roll Forming Machine to match your raw material production.

3. We provide processing services on behalf of you. You only need to transport the purchased raw materials to our company. After producing the products for you, we can package them and transport them to your country; LIMING is your overseas OEM.

Solar Bracket Roll Forming Machine Production Process:

|

No.

|

Item

|

Parameter

|

|

1

|

Coil material

|

0.8-3.0 mm steel(according to customer’s request)

|

|

2

|

Rollers material

|

Gcr15 bearing steel, quenching (HRC55-58)

|

|

3

|

Shaft material

|

45#forge steel, thermal fining

|

|

4

|

Cutting blade

|

Cr12Mov, heat treatment(HRC58-62°)

|

|

5

|

Driving method

|

by gearbox

|

|

6

|

Working speed

|

30-100 m/min

|

|

7

|

Dimension

|

about 25*1.5*1.5 m (length*width*height)

|

|

8

|

Weight/ Container

|

about 15T/ one 40’GP

|

1.Does one machine can only produce one size?

Not exactly, it depends on the machine.

2.Do you have after sales support?

Yes,we are happy to give advice and also have skilled technicians available to maintain the machine if needed.

3. You are trade company or factory?

We are Manufacturer.

4.How long the machine could be made?

Normally speaking, high precision roll forming machine could be made out with 40 working days.If you need machines in hurry, we

can make it for you less than a month.

5. Do you provide customized?

Sure, we can design the equipment according to the data of the structural section you provide.Our engineers can offer the best

professional solution to our worldwide clients.Meanwhile we can provide door-to-door service.

6.How to visit your factory?

By high speed train from Beijing to cangzhou, half an hour.

7.What’s the warranty period?

12 months warranty period, starting from the date of the successful installation and commissioning of the equipments at the

Buyer’s Installation site.

8.May we visit your factory?

Sure,Warmly welcome to our factory at any time.