Slitting Strip Production Line

Slitting strip production line for making

light steel structure includes the follow parts:

- Hydraulic decoiler: load the material,

feeding the material;

- Slitting and shearing unit: slitting the

sheet to get the required width;

- Tension unit: pressing fix device;

- Hydraulic recoiler: recoiling the finished sheet.

Slitting strip production line–Hydraulic

decoiler

Active un-coiler: active to uncoiling.

Width of steel coil: 1250mm.

Inner diameter of steel coil: 508-610mm.

Outer diameter of steel coil: φ1500mm.

Material of main shaft: 40Cr.

Pneumatic damp pressing arm.

Uncoiling speed: about 30m/min

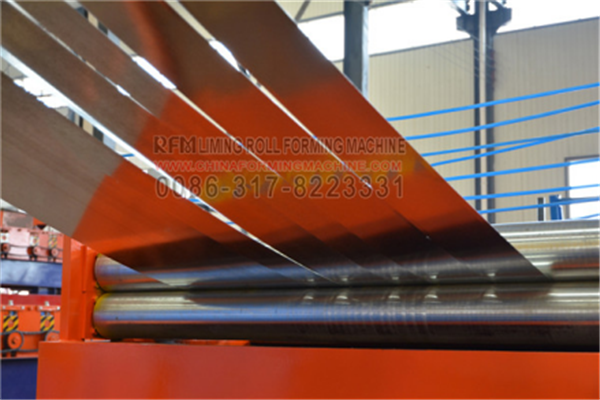

Slitting strip production

line–Flatenning-slitting

Coil material: Galvanized sheet, aluminum

plate, PPGI, GI

Width of material:1250mm;

Slitting speed:about 30m/min;

Slitting width tolerance: ±0.5mm;

Work pressure of hydraulic system: 12Mpa.

Slitting strip production line–Tension

Unit

Slitting strip production line–hydraulic

recoiler with pressing arm

Active re-coiler: active to recoiling.

Width of steel coil: 1250mm.

Inner diameter of steel coil: 508-610mm;

Outer diameter of steel coil: φ1500mm;

Material of main shaft: 40Cr.

Pneumatic damp pressing arm

Recoiling speed: about 30m/min.

Our factory established in 1996, is

professional manufacturer.

Our factory is the biggest designing and

manufacturing supplier of roll forming machine in North China.

We have the full professional engineer

team, which have rich experience for many years.

We can customize machine as per detail

profile drawing.

Our machines have passed CE certification

through the inspection of BV company. This certification has the highest

authority in this industry.