Slitting line factory price Slitting line machine used for slitting aluminum strip

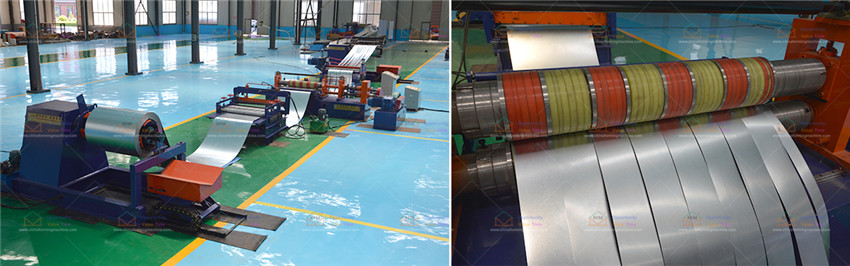

Mr. Lachance from Canada shared a client I met recently, he wanted a slitting line to divide wide rolls into narrow rolls.

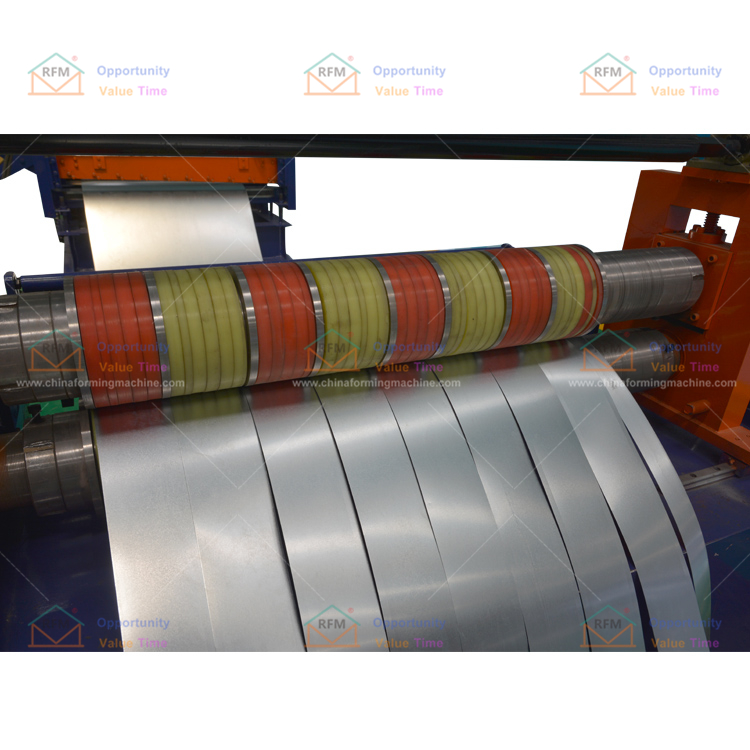

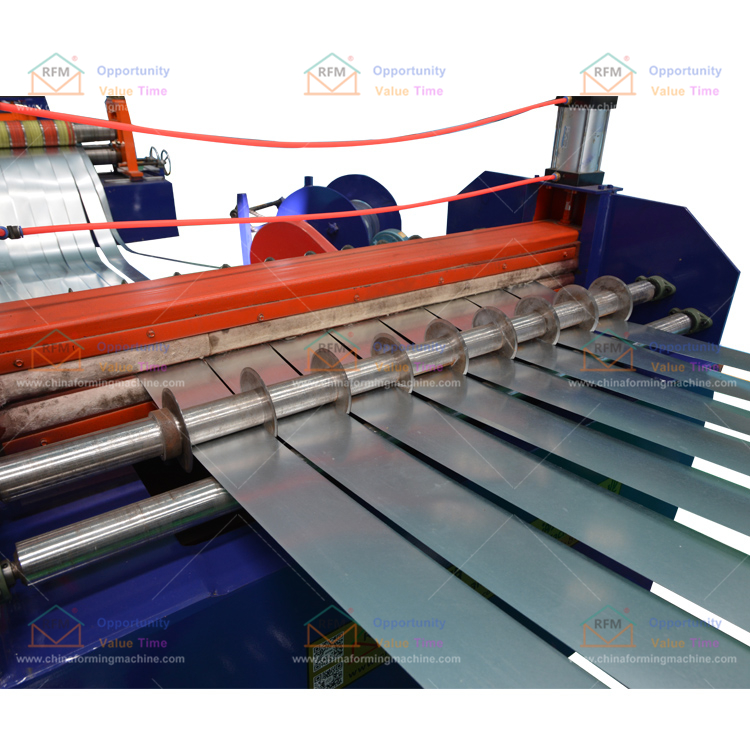

In the previous purchase experience, because the coil spare parts are modulated, they cannot be automatically wound and need to be collected manually, which not only delays time, but also increases labor costs and reduces production efficiency. He felt very sad about this. Until he met us, our slitting line can automatically wind up after slitting, and the slitted narrow coils can be collected by themselves, and then automatically fed into the forming machine, which is very convenient.

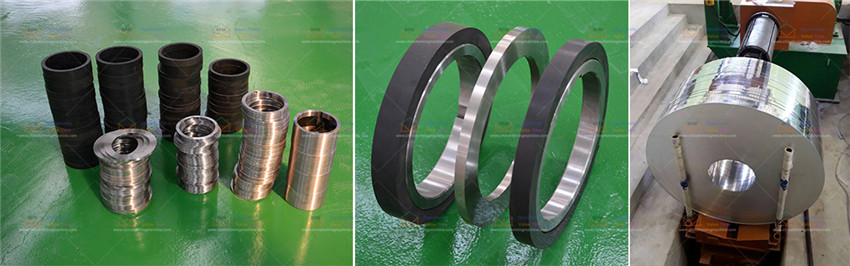

The slitting line we produce can not only improve production efficiency, but also save labor costs and increase automation. After our slitting production line is completed, we will conduct inspections at all stages from production to final loading. Each part has a dedicated person responsible for inspection, which can prevent us from losing parts during loading. And can carry out trial run test, understand the slitting effect of the slitting line in advance, to ensure that the final product produced meets the needs of customers.

Our rigorous attitude has won the trust of Mr. Lachance, and we feel very happy to cooperate.

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

Our company possesses the international first-class technical team and strives to tackle the difficulties in production efficiency and labor saving. As the “High-Tech Enterprise”, Liming has undertaken the mission of “China Building Materials Machinery R&D Center”. The models including CNC50 and CNC100 promoted by us have solved the low speed problem of 15 meters and 30 meters in the ROLL FORMING MACHINE industry.