Supermarket shelf profile shelf post equipment forming machine manufacturer

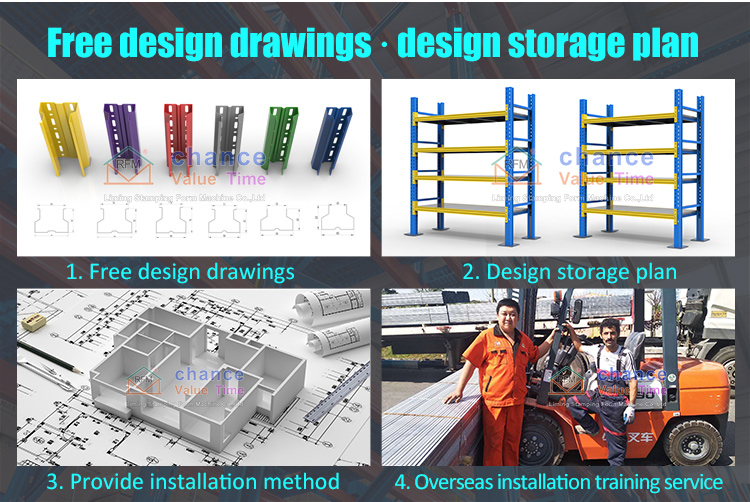

Bruce is from Mexico. He is the owner of a profile factory. He opened many branches across the country. The supermarket he cooperates with has a great demand for shelves, and supermarket shelves can be used to store a large number of commodities. So he found us on the Google website and sent us an inquiry.

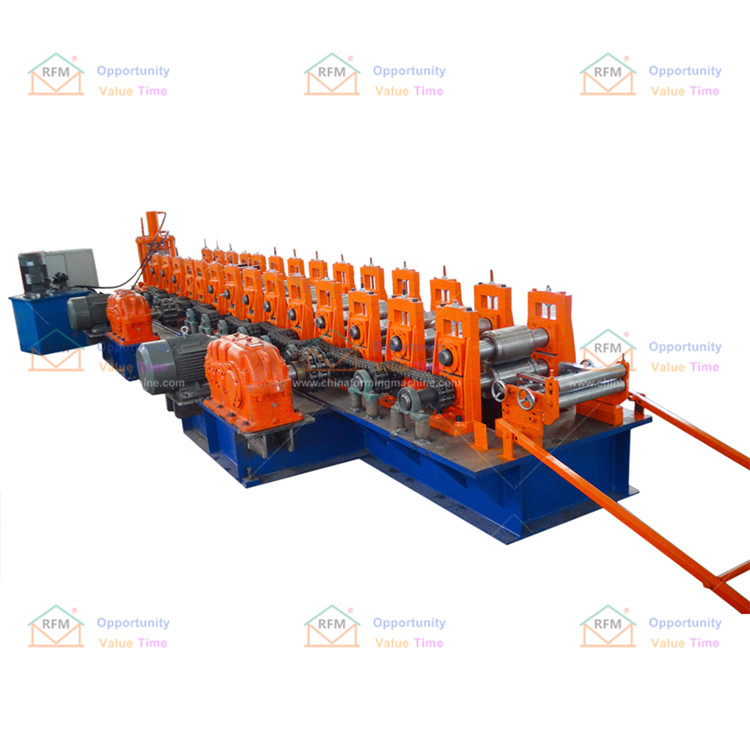

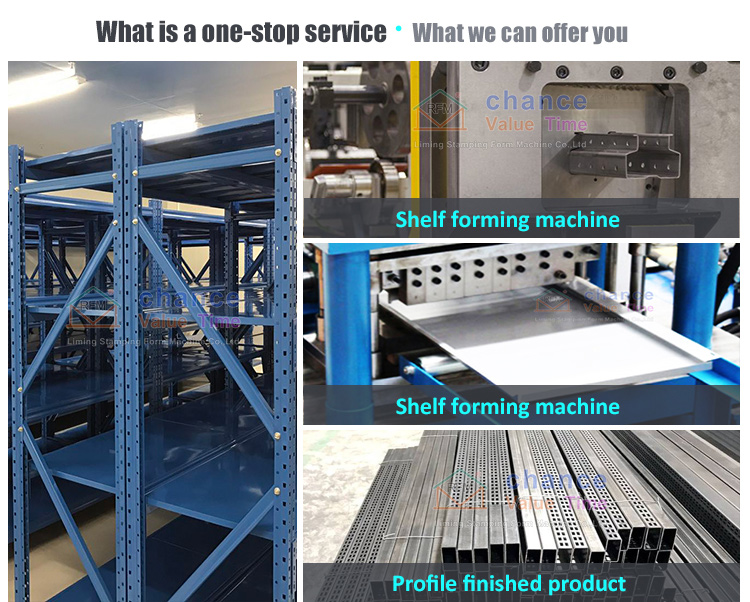

The shelf post equipment forming machine developed by our company includes:

–shelf post equipment forming machine

-Shelf laminating machine,

-Rack beam (replacement beam) cold bending machine,

-Automatic production line of shelf step beam (P beam),

-Shelf reinforcement equipment,

-Shelf label trough production equipment,

-General purpose angle steel production equipment for shelves,

-Shelf beam cold bending forming machine

-Light-duty warehouse rack columns,

-Automated production lines such as storage rack columns.

The racking equipment consists of: uncoiling, discharging, leveling, feeding, punching, forming machine, fixed-length cutting, receiving platform, electric control box (PLC control), etc.

Shelf post equipment forming machine, where the punching equipment adopts rolling punching, the maximum speed can reach 200m/min. This equipment improves the low-efficiency and slow-speed punching machine.

What is a rolling machine

Features of shelf equipment:

1. The shelf column forming machine adopts PLC full-process intelligent control, high automation program, safe and efficient.

2. The forming frame is welded by high-strength channel steel. High strength and long service life.

3. The material of the roller is 40Cr, and the hardness is HB280 after quenching and tempering.

4. The material of the forming mold is GCr15, quenched, and hardness: HRC 56-62℃.

5. The transmission structure is gear box transmission or chain transmission.

Due to the user’s pursuit of production speed and the precision requirements for neat cutting, the production equipment has a variety of manufacturing processes; customized equipment can be provided according to user requirements.

The design of the machine is compact and reasonable to ensure the precision of roll forming. After receiving the product, Bruce liked our product very much and brought him a lot of benefits.