Seamless Gutter machine

The Seamless Gutter machine adopts a wall plate structure, the base is 30# hot-rolled I-beam integral welding, the wall plate is welded on the base, and the vibration stress relief method is used to eliminate the welding stress and ensure the rigidity of the overall frame. stability.

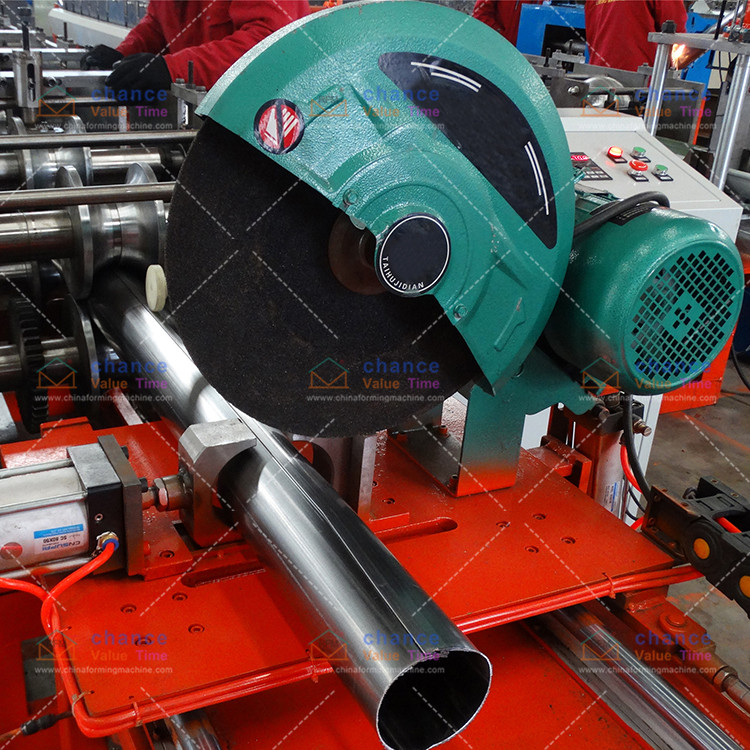

The Seamless Gutter machine adopts hydraulic forming punching technology, 4 sets of special cutters are operated at the same time, and the shear section is neatly deformed and the amount of deformation is small. Cutter material Cr12, hardness HRC58-62° after heat treatment, shear section is tidy without burrs. The cutting mechanism is composed of knife seat, hydraulic cylinder driving mechanism, cutting blade, supporting hydraulic station and so on. The hydraulic system includes oil tank, oil pump, solenoid valve, pipeline and so on.

Features of Seamless Gutter machine :

1. The main shaft of the gutter downpipe forming machine is made of 45# round steel quenched and tempered heat treatment to ensure its good comprehensive performance. The shaft diameter is φ65mm.

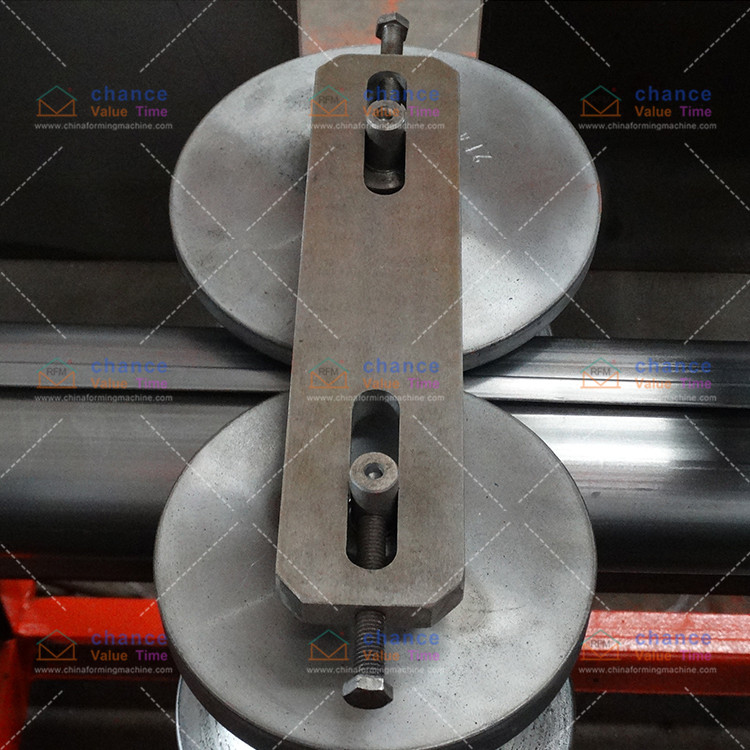

2. The deformation of the unit adopts 18-20 horizontal rollers (depending on the shape and size of the downpipe), horizontal rollers, a large number of suspension rollers, and core rods and other components. The deformation process is smooth and natural, and all components reach very high precision.

3. The roller of the Seamless Gutter machine is made of 45# forging by CNC lathe. After heat treatment, the hardness of the substrate can reach HRC45 degrees, and then the surface is hard chromium plated with 0.05mm, which ensures the dimensional accuracy of the roller and the surface finish. The service life.

4. Electrical configuration of gutter downpipe forming machine: The electrical control of the unit adopts a full set of Panasonic series configuration, including Panasonic series programmable industrial PLC, Panasonic series touch display, Panasonic VF series inverter, etc., additionally equipped with Omron encoder, overall electrical system, It is stable and can be installed on the base of the main unit as a whole. No additional wiring is required during production operation, which is fast and convenient.

5. The Seamless Gutter machine is equipped with a set of cantilever type raw material loading racks, the inner diameter of the loading can be customized according to user requirements, bearing 2 tons; equipped with an integral roller discharge rack, 10 meters in length.

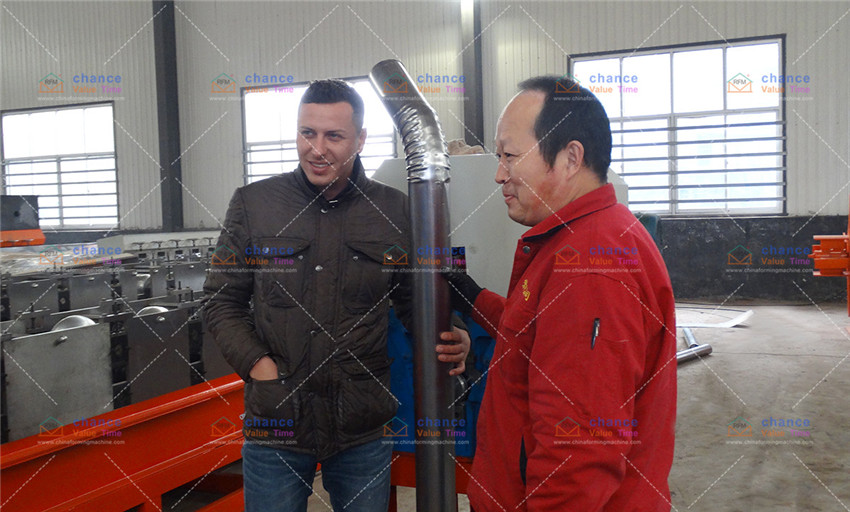

6. Bending and necking machine: The principle of cam connecting rod is adopted. All the bending molds and locking molds are CNC-processed, manually polished and carefully made. The power of the tube bending machine is 2.2kw. The bending angle is 90-180 degrees, and the corresponding number of folds can be bent according to user needs.