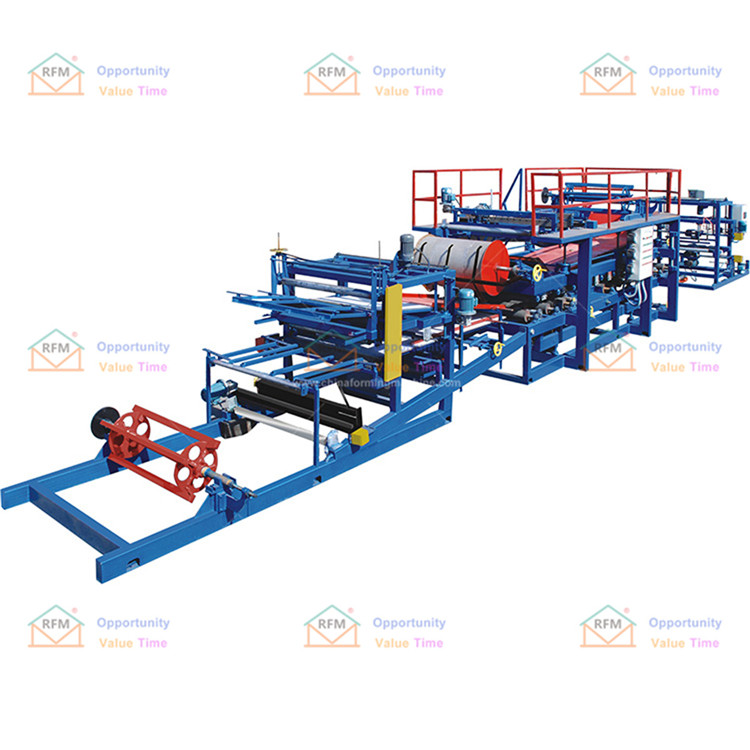

Rock wool sandwich plates, as a building material with very diverse functions, is very popular in the market. A customer I recently met, Mr. Zuluga from Colombia, wanted to purchase a rock wool sandwich panel roll forming machine. In his previous purchasing experience, he was very worried about the supplier`s production technology. Because when the sandwich panel was engaged , if the occlusion is not good, it will greatly affect the use.

When he met us, we have 24 years of production experience, our production experience is constantly enriched, and production technology is also constantly mature. The workers we hire are all workers with technical qualifications. The high-quality personnel can reduce the problems that may occur in production as much as possible. Avoid bad bite

After the machine is finished, we will use raw materials to test the machine. Once the product does not meet the customer’s requirements, we will correct it immediately.

And in our workshop, there is a simulated installation scene of the composite board. After we saw our final product and the bite scene of the composite board, Mr. Zuluga dispelled the doubts.

We have reached a pleasant cooperation.

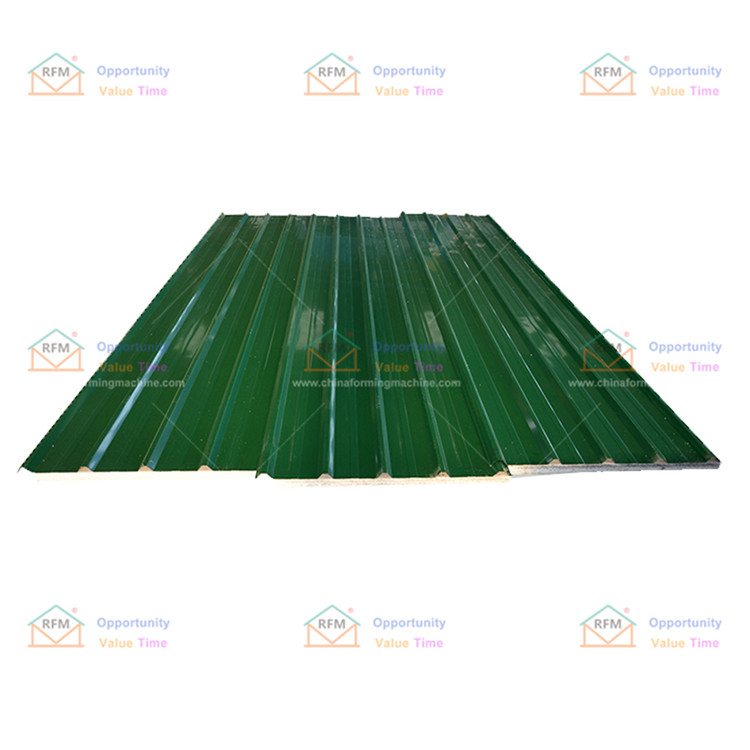

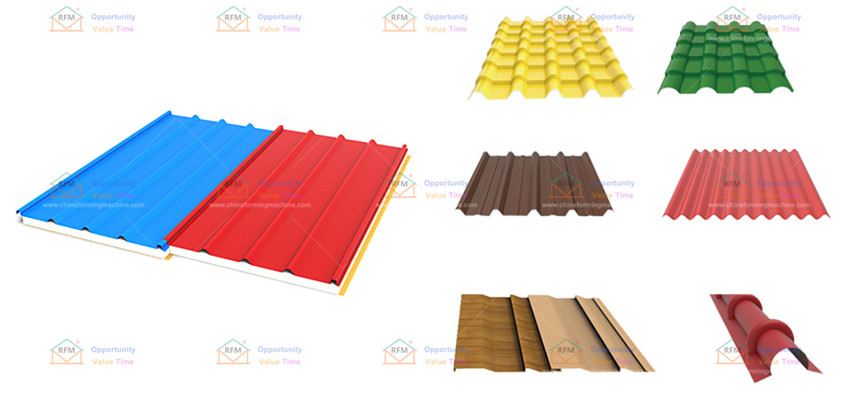

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

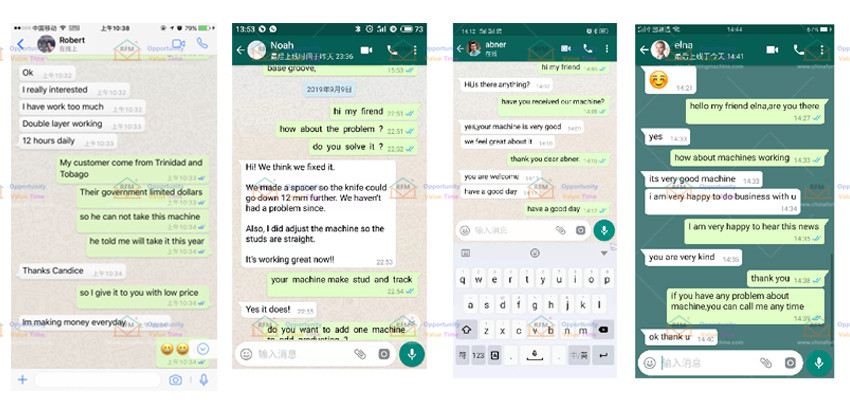

Customer Feedback