Our company provides Russian special automatic color steel roof tile roll forming machine. With rich experience, professional knowledge and rich technical personnel, we have manufactured high quality machines that sell well overseas

In July, I met a Russian customer who wanted the C20 automatic color steel tile press. Although The C20 tile is a single layer of color steel tile, but its artificial insulation is convenient, very suitable for easy to add insulation materials, tile peak size moderate, tile peak density, high strength. We provide C20 automatic color steel tile press. This equipment is automatic machine, adopts pressing wheel roller forming, presses the product appearance beautiful, durable, widely used in building roof, wall and outdoor decoration. The machine is controlled by computer controller program, automatically fixed length, automatically cut off, with touch screen operation, simple and convenient.

We have been committed to the development and research of new products, constantly improving product technology, and driving the development of the machinery industry with truth-seeking, quality and innovation, and have made remarkable achievements.

Application Range & Scene

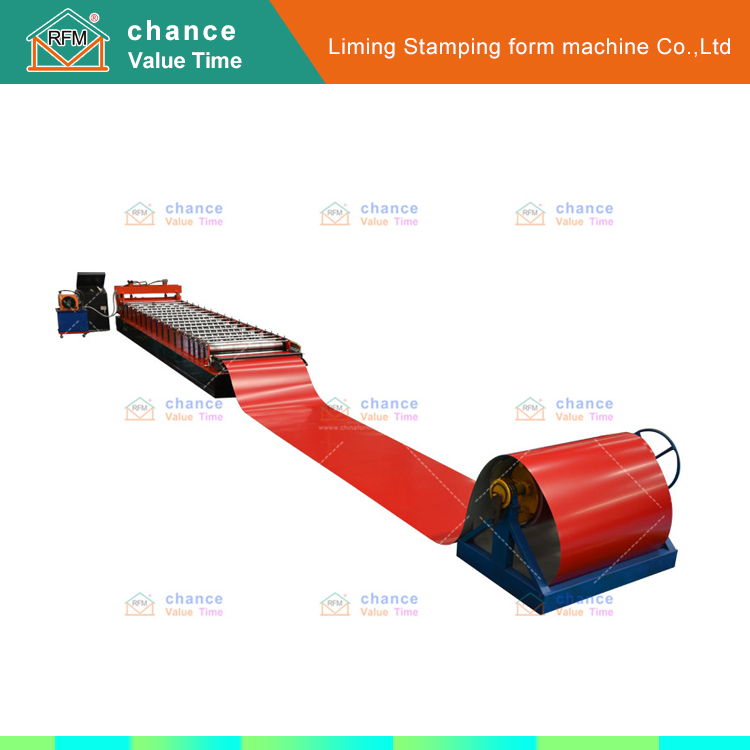

Roof tile roll forming machine’s production process

Un-coiler that inputs and releases coil, Roll Forming Unit that makes shape of coil, and Shearing Unit that cuts the fabricated roof panel, Drawing Unit applying steps to products at the constant depth is adopted. Auto Stacking Unit is a device that loads the completed roof tile sheets after cutting properly, and it can discharge products in various ways after loading.

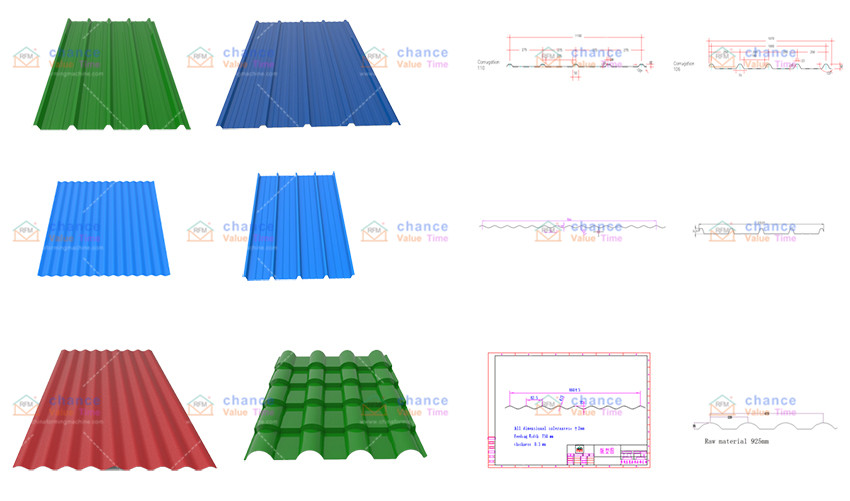

Roof tile roll forming machine’s profiles

This Roofing panel roll forming machine is the special equipment for continuous rolling and cold-forming on steel sheet. It adopts coiling steel sheet as the raw material, decoiling, then continuous rolling and cold-forming, automatically cut to the size and output the finished panel to the supporter. Roof tile making equipment is really a new type of energy-saving and high-effective producing equipment for steel structure.

| Material | Al/Zinc/GI/PPGI |

| Thickness of material | Min. 0.3mm~Max. 0.6mm |

| Width of material | Min. 914~1,390mm |

| Production speed | Max. 8~13m/min |

| Drawing depth | 250mm, 14~20tiles/min |

| Drawing height | 15~25mm |

| Adjustable pitch range | 250~400mm |

| Drawing and cutting method | By hydraulic(Flying cutting) |

| Control system | PLC computer control and inverter |

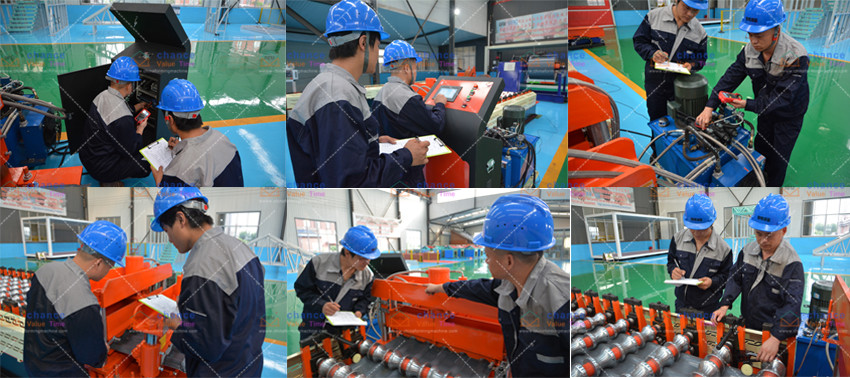

Professional Inspection Process of color steel roof tile roll forming machine

Customers’ Application Projects

Inspection/Package/Delivery

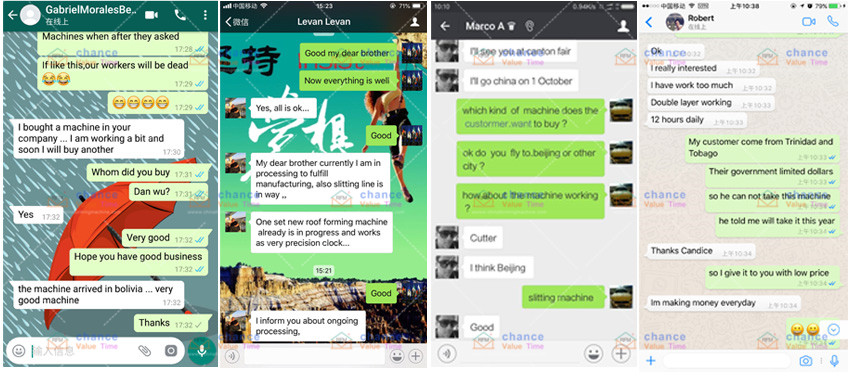

Customer Feedback