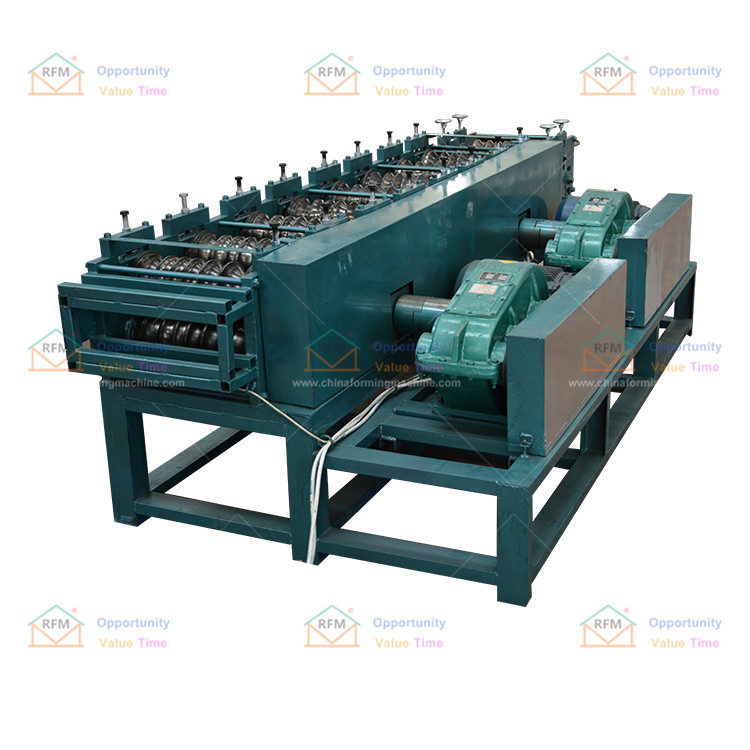

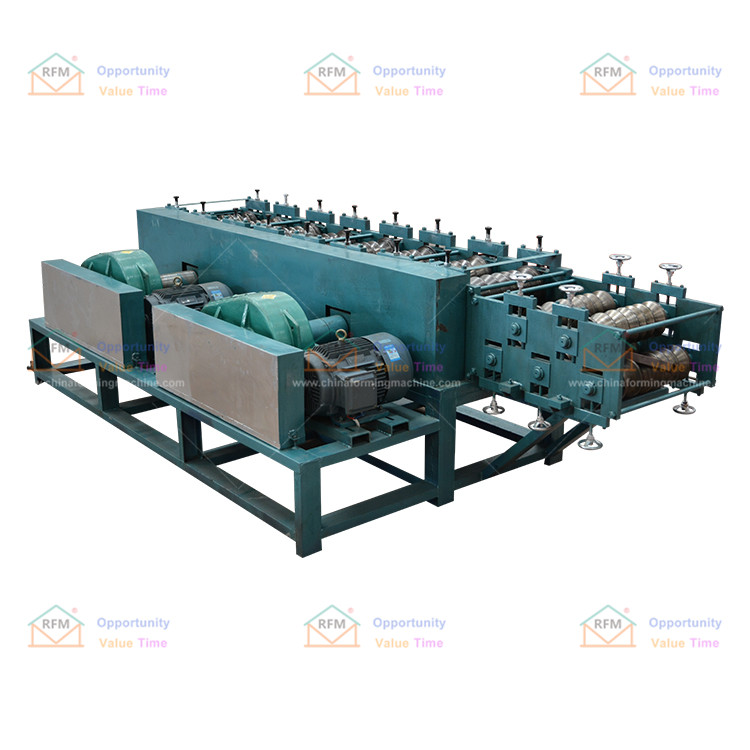

The new cold bending and rolling technology concept makes the automatic tube square tube secondary forming equipment also has the advantages of operation, maintenance, maintenance, mechanical debugging and easy mold change.And the production automation degree is high, the cost is low, very durable.

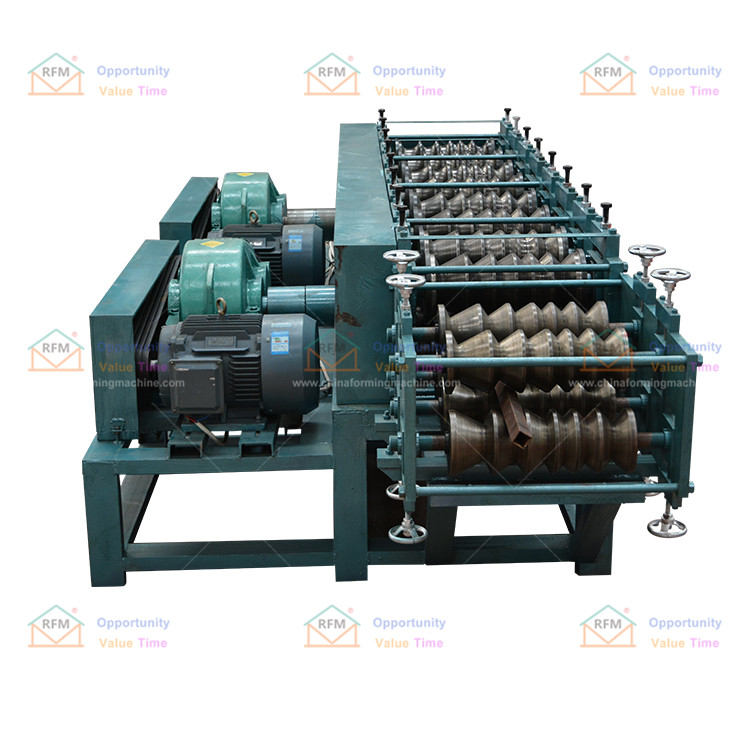

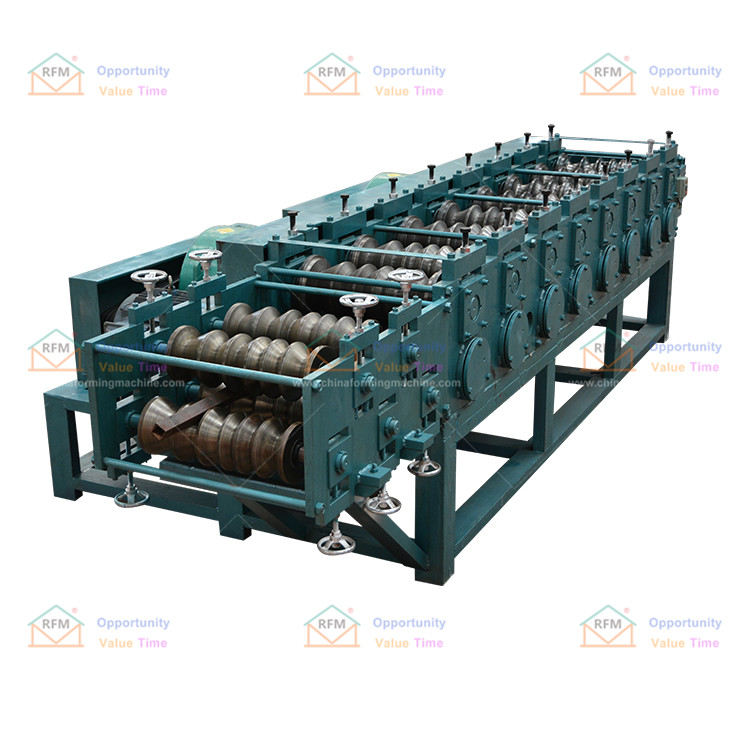

The roller roller of the whole pipe changing square control pipe machine adopts the high-precision Cr12 material pressing roller mold, fine turning, fine grinding, hard winding plating, etc. The production process is quenched at high temperature, the pressing roller mold is formed by cold bending, so as to maintain the appearance of the finished product, no sliding paint, and achieve low wear!The roller is durable, anti – wear and long service life.

Standard pipe pressure tube machine, pipe become square pipe molding equipment manufacturers, in the dawn molding machinery, with the increasing demand for oval tube, coupled with the manufacturer of custom square tube of the high cost factors, many customers choose directly buy a round tube, square tube flattening machining ways, not only reduces the cost, improve the working efficiency, is your ideal equipment processing square tube.

Pipe become square controlled machine equipment lines from the pipe to the square tube series of automatic production process, the whole production line adopts automatic roll forming operation mode, the prepared pipe through multiple rows of seiko roller wheel orderly formation of square pipe after rolling, the whole process was input to pipe data in the computer controller, one key start, the machine automatically rolled square tube, without human involvement in the whole rolling process, simply workers sorting finished plate, entity.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

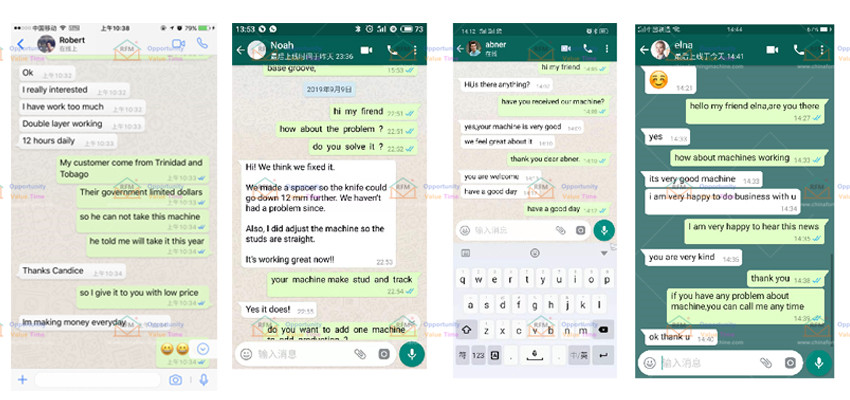

Customer Feedback