Boost Your Production Efficiency with the Latest Roofing Sheet Making Machines

Some time ago, a customer asked us about the roofing sheet making machine.

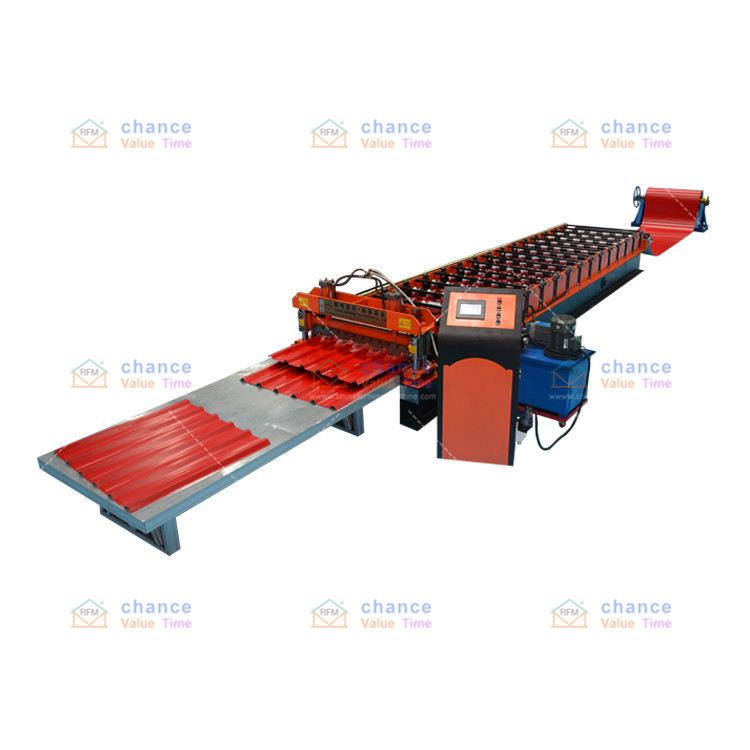

The single-layer color steel roofing sheet making machine is composed of upper and lower rubber rollers, racks, power transmission and control devices, and film support. It has the characteristics of flat film, no wrinkles, no bubbles, and long service life.

The roofing sheet making machine has models such as operating device, automatic film cutting, feeding table, and adjustable feeding speed.

roofing sheet making machine is widely used in stainless steel plates, aluminum plates, glass plates, aluminum-plastic panels, craft lenses, lens plates, sandwich color steel plates, plates, decorative panels, glass plates, PS, PE, PVC panels, and sunshine panels (poly Carbonate board), anti-theft doors, signs, coated glass, and other flat-panel surfaces are coated, attached, and pressed with adhesive PE protective film, so that they are not polluted, corroded, or scratched during production, processing, transportation, storage and use.

Each of our roofing sheet making machine can protect the original smooth ,shiny surface and lens cracks of the final profile.

We are a professional roofing sheet making machine manufacturer.

Metal roof sheets are an affordable option, able to withstand high temperatures.for this purpose, LIMING roofing roll former offer to you Roofing Sheet Making Machine and Roof Panel Roll Forming Machine.

in addition to, A rolled metal roofing is lighter than a concrete or clay tile roof and more durable than an asphalt shingle roof, and easier to handle than long-run metal roof tiles.

It is the best reliable and affordable roofing system in the market place in a range of design and styles,Roof tiles can now mimic other roofing materials such as wood shake and asphalt shingles, and slate, however, the metallic look often compromises the authenticity of these renditions and the overall design.

If your output is large, we have a high-speed 50/min Roofing Sheet Making Machines

Click to watch the video

Roofing sheet making machine features:

Lightweight, high impact strength and simple to use.

Deep corrugations provide bold aesthetic shadow effects.

The strength of design allows longer spanning or greater allowable loads.

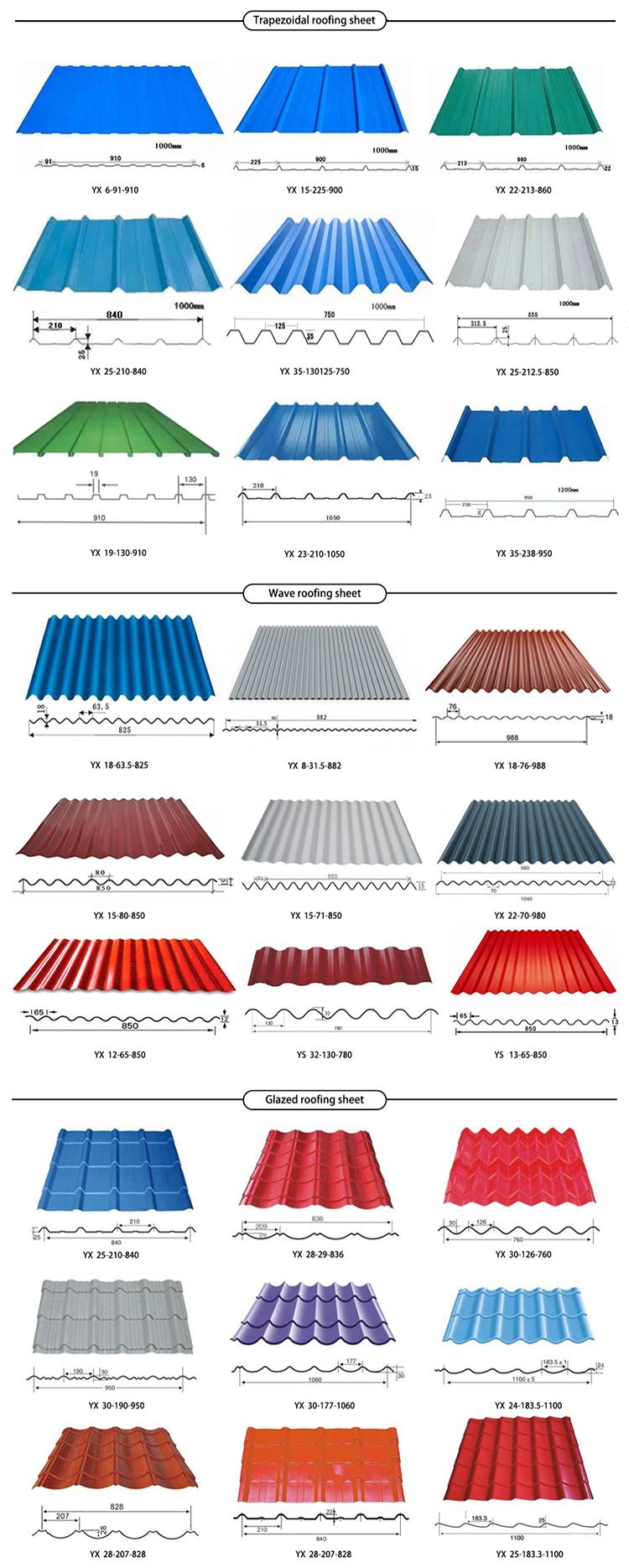

Various corrugation profiles, including standard, mini, tile effect, box profile, etc.

Offer Custom-manufactured service to satisfy your special needs.

Offer roof materials in galvanised steel, prepainted galvanised steel, also available in galvalume steel and prepainted galvalume steel.

Offer roof accessories to help you install roof or wall panel, such as roof fasteners, roof panel machine and roof cutting tool.

Choose drawings for customization

|

NO.

|

Item

|

Specification

|

|

Material

|

Raw material

|

Galvanized steel or PPGI

|

|

Thickness

|

0.3-0.8 mm

|

|

|

Machine

|

Roller station

|

13 or depend on customer’ drawing

|

|

Shaft diameter

|

75 mm

|

|

|

Solid shaft material

|

High grade 45# steel with Cr12 mov coated,

quenching & tempering & treatment

|

|

|

Roller material hardness 30-40 HRC

|

Cr12

|

|

|

Machine size

|

About 6*1.5*1.3 m

|

|

|

Machine weight

|

About 5 tons

|

|

|

Machine color

|

As customer need

|

|

|

Working speed

|

15-50 m/min

|

|

|

Cutter

|

Hardness

|

50-65 HRC

|

|

Cutting tolerance

|

± 1mm

|

|

|

Material

|

Cr12

|

|

|

Operate

|

Hydraulic cutting

|

|

|

Power

|

Driving way

|

Chain 1 inch

|

|

Main motor

|

4 KW

|

|

|

Pump motor for cutter

|

3 KW

|

|

|

Voltage

|

380V/50HZ, 3P or Customized as customer’ request

|

|

|

Control system |

PLC brand

|

Delta made in Taiwan

|

|

Screen

|

Touchable screen

|

|

|

Language

|

Chinese and English or add customer need language

|

|

|

Decoiler |

Operation

|

Manual

|

|

Weight capacity

|

5 Tons

|

|

|

Price

|

Free as gift

|

|

|

Receive table

|

Operation

|

Manual

|

|

Length

|

3 m

|

|

|

Price

|

Free as gift

|

FAQ

Q1. How do I choose the right machine for me?

1. A machine doesn’t just provide a few photos to prove what they can produce

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You don’t show the product I need, can you manufacture it?

Our company’s engineers have studied in well-known European cold bending companies and have great advantages in machine design and R&D and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 40 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate, and have a longer service life.

The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, 26 years of production experience, to be a service company that you have the strength to guarantee

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don’t have your own outline drawing, we can recommend some models according to your local market standard.