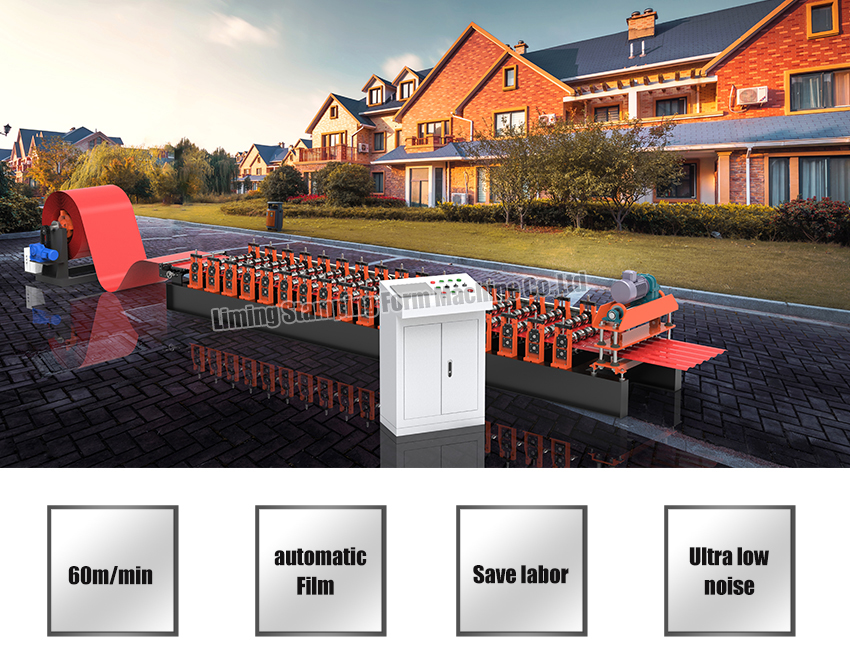

2021 Hot-selling factory price 60m/min high-speed metal roofing sheet making machine

Liming roofing sheet making machine offers manufacturing applications for a great number of metal roofing product designs and types covering both roof tile panels and trapezoidal roofing profiles. These are made by LIMING production lines, well-known for their reliability, efficiency and innovative technologies.

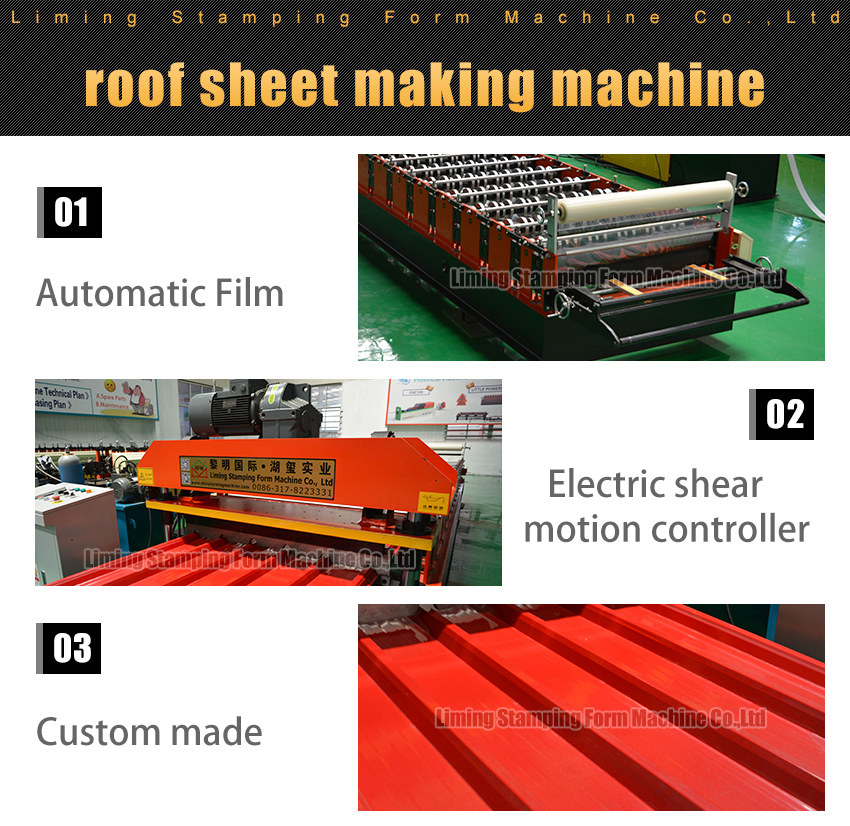

LIMING roll forming machine company has an extensive experience in roofing sheet making machine as well as in manufacturing technologies. We offer wide range of metal roof tile designs and can also create completely new product innovations according to specific customer requirements.

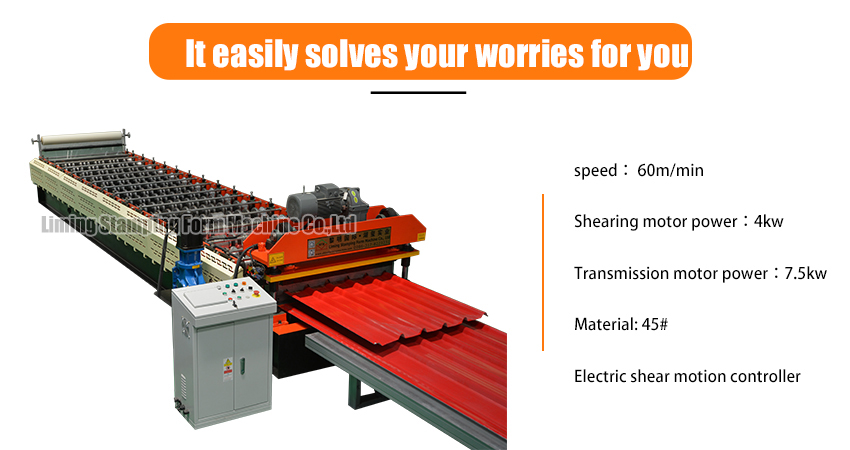

The combination of world-class AI intelligent control technology and 5G technology provides the customers with remote upgrade services for the roofing sheet making machine. Under the mechanical function, the speed module and LOGO stamping module are upgraded remotely, we continue to optimize the products for you and help you win in market competition. Give us one chance to add the value for your machinery and create more value for you.

Our machine range for roofing sheet making machine:

1.Classic custom-length metal roof tile profiles (from ridge to eave)

2.Modular roof tile panels (standard-length panels and custom-length profiles).

3.Roof tile products for roofing with concealed fixing

LIMING roofing sheet making machine produces high-quality lines for efficient production of trapezoidal and corrugated profiles, as well as standing seam products. We have a wide range of profile designs from classic sinusoidal profiles to deep decking products. We can also custom-design the machine with additional features and innovations according to customer needs.

LIMING machine lines are well-known for their reliability and flexibility. Our roll forming lines are made of premium quality parts and components offering a long-lasting production solution.

Application Range & Scene

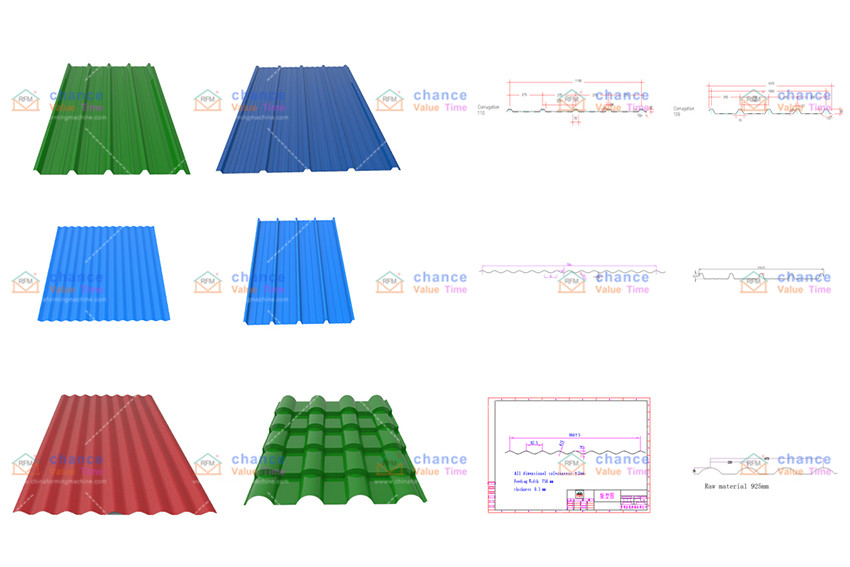

roofing sheet making machine system has a big range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile panel, metal deck panel, standing seam panel, K span panel and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.

The normal machinable thickness range of our roofing sheet making machine is 0.2mm-0.8mm, the standard or more used in international market is Gauge 26 (0.45-0.5mm), working raw material is Aluminum, PPGI, Galvanized steel, Galvalume steel etc. We confirm machine’s configuration according to your drawing, specially the pitch and height of each wave. Linbay Machinery is always your best choice of roof panel roll forming machine.

Roofing system roll forming machine’s metal sheet profiles

| roofing sheet making machine | ||

| Machinable Material : | A) Galvanized Coil | Thickness(MM):0.3-0.8 |

| B) PPGI | ||

| C) Carbon steel Coil | ||

| Yield strength : | 250 – 550 Mpa | |

| Tensil stress : | 350 Mpa-550 Mpa | |

| Nominal forming speed(M/MIN): | 0-20 | * Or according to your requirement (Optional) |

| Forming station : | 22 stands | * According to your profile drawings (Optional) |

| Decoiler : | Manual decoiler | * Hydraulic decoiler or double head decoiler (Optional) |

| Punching system | No | * Hydraulic punching or punching press (Optional) |

| Main machine motor brand : | Sino-Germany Brand | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Forged Iron station or torri stand structure (Optional) |

| Rollers’ material : | Steel #45 | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (optional) |

| Frequency changer brand : | Yaskawa | * Siemens (optional) |

| PLC brand : | Panasonic | * Siemens (optional) |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

Professional Inspection Process

Inspection/Package/Delivery

Customer Feedback

Liming Stamping Form Machine Co.,Ltd is a manufacturer specializing in all kinds of pressing, cold bending forming equipment and automatic production lines. We have an excellent team with strong technology and strong sales, providing professional products and related services. We focus on after-sales service and have received good feedback.

Please believe us due to our development history with constant efforts, reject the low-quality competitive small factories and trade companies that change industries at any time with our technology and strength. Please give us a chance to show you every aspect of our group.

Our products have been sold to more than 200 countries all over the world. Including the United States, Germany, Dubai、Saudi Arabia, Algeria, Colombia, Peru

Main products for sale:

roofing sheet making machine

shutter roll forming machine

cz purlin roll forming machine

Gutter roll forming machine

Cable roll forming machine

Coil processing equipment

Stud and Track roll forming machine

sandwich panel roll forming machine

solar photovoltaic panel roll forming machine

Slitting line