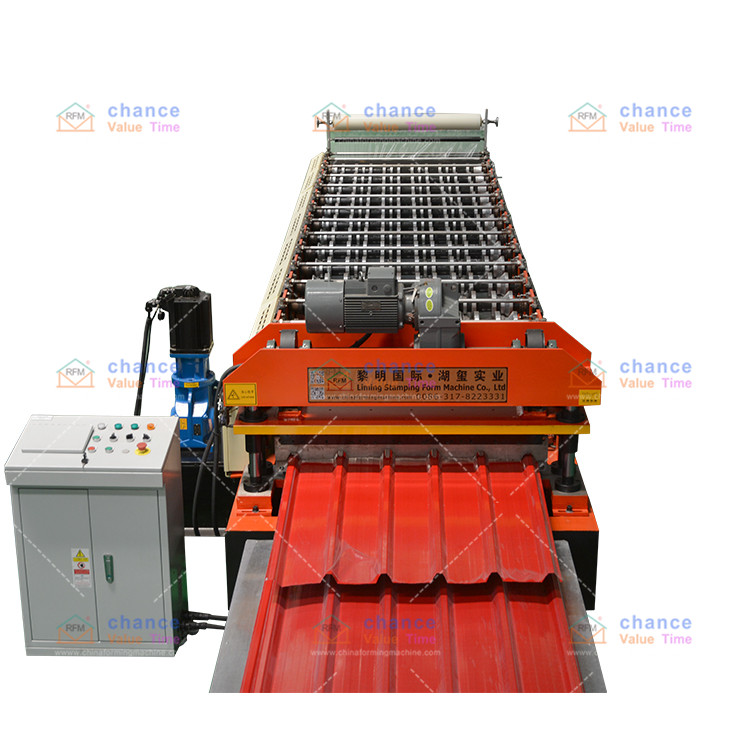

2021hot selling higt speed 50m/min metal roofing roll forming machine

The usage of the metal roofing roll forming machine Forming rollers?

The quality of the machine can vary greatly where you don’t pay attention. Some roof panel machines on the market are more expensive than us, and some are cheaper than us.

Some inferior machines are exposed as high-quality machines, but the price of high-quality machines is very high, so we have broken down the material of the machine configuration, and the price is the cost price for you. We only add some processing costs for the workers. , So our quality is high but the price is cheaper than other factories.

Forming rollers – Forming rollers and forming stations are the individual components that the metal passes through to bend or form a desired shape. Forming rollers are put together in a progressive series to complete a process used to form the end product. Most rollers are made of hard-chromed steel. For some roofing sheet machine, the forming rollers are also the drive rollers.

Drive rollers – Drive rollers are used to move the metal through the roofing sheet machine. Some rollformers incorporate the forming and driving rollers into one, while others keep the drive and forming functions separate. Separating the two results in less stress on the metal.

Forming stations – Forming stations refer to the spots at which the metal is bent or manipulated by a pair of forming rollers. In fact, the more forming stations there are in a fast speed color steel roofing sheet machine, the higher the quality of the finished product because a gradual forming reduces stresses inflicted on the material.

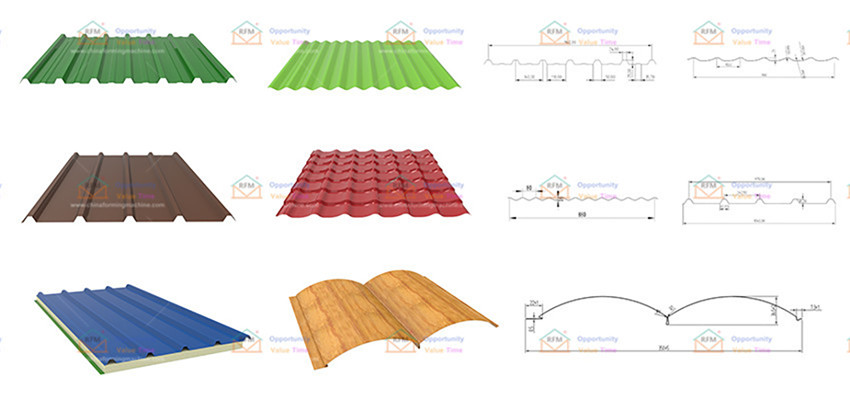

Application Range & Scene

Provide Installation Method & Customized Profile For Free

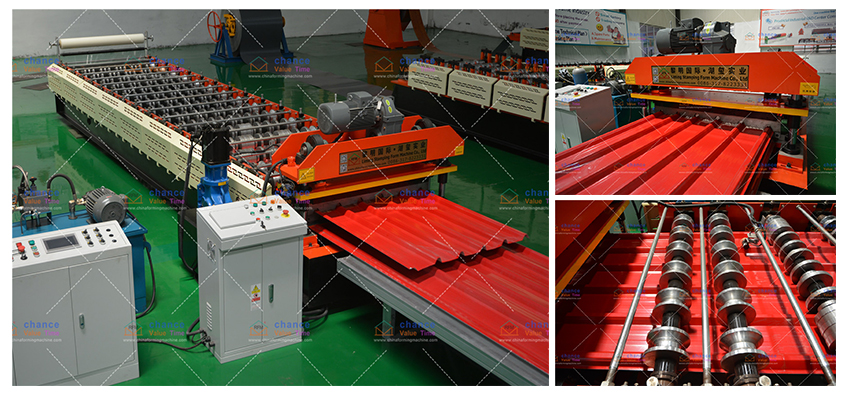

Professional Inspection Process

Customers’ Application Projects