How to judge the impact of the quality of the wheels of the roof panel roll forming machine on the product

- PRODUCT DETAIL

How to judge the impact of the quality of the wheels of the roof panel roll forming machine on the product

A customer from Jordan, Farouk. He wants to purchase a new Roof panel roll forming machine.

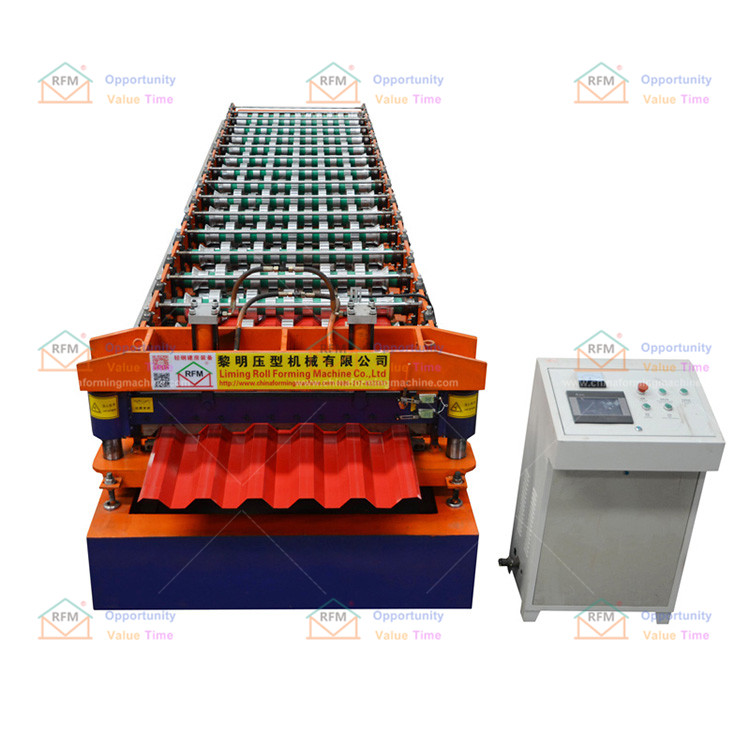

After the previous Roof panel roll forming machine has been used for a period of time, the wheel has broken, and the wheel is the most important part of the machine. A damaged wheel will affect the final product. The molding process will scratch the surface of the final product, which will delay the use of the entire machine. So this time we test the wheels of the machine.

We first mark the relatively weak points of the wheel shape, and then use a steel hammer to beat it hundreds of times without leaving a trace of scratches.

Then we explained to him how our wheels are processed. The raw materials we use are from large state-owned steel mills, so there is no need to worry about the quality and service life of the steel. After grinding into wheels according to customer requirements, we will use CNC machines to process the wheels to ensure the accuracy of the wheels. After that, we will conduct hardness resistance and pressure tests on the wheels. After testing the qualified wheels, select all the unqualified wheels. Our machines only use qualified wheels to ensure the service life of the Roof panel roll forming machine.

We showed Mr. Farouk our factory and our process of testing wheels. Mr. Farouk was very satisfied and saw our rigorous and serious attitude in doing business.

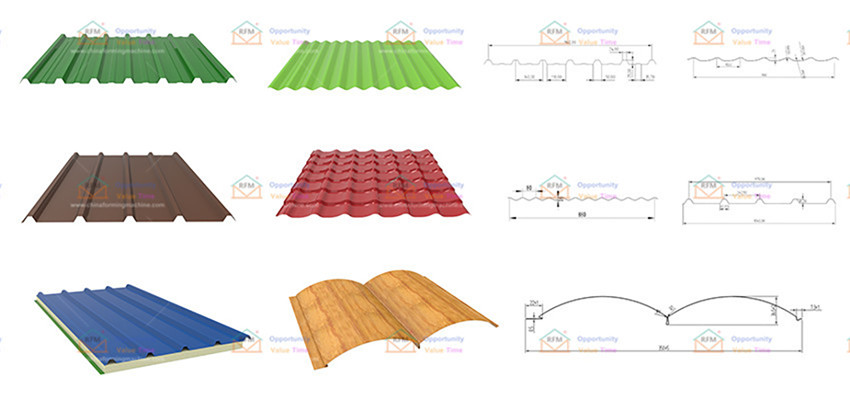

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery