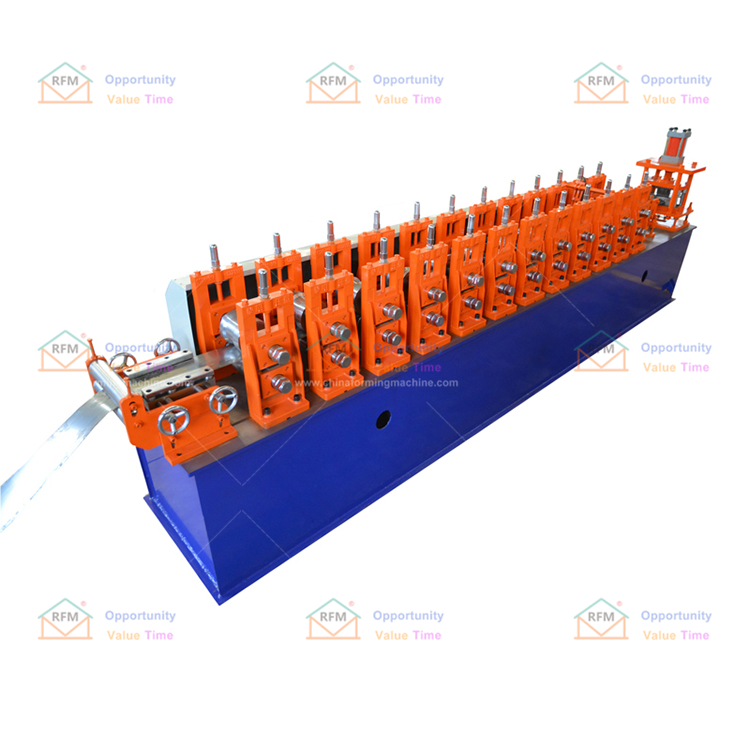

2024 factory sale rolling shutter door forming machine

Mr. Jackson is a manufacturer of rolling door from Morocco.

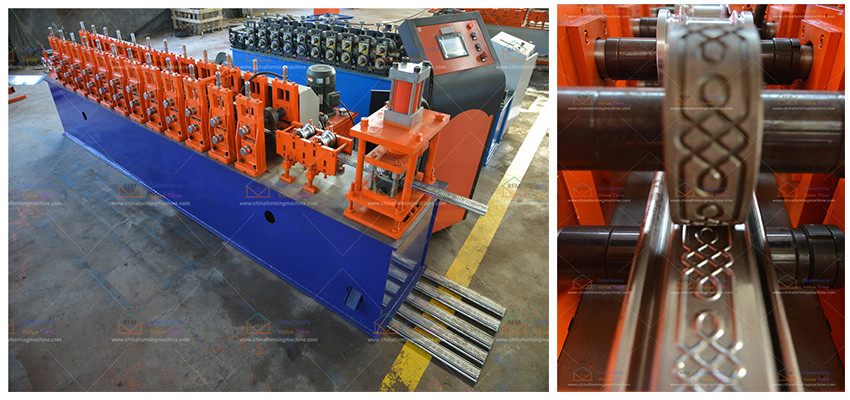

His company is large and can manufacture all kinds of rolling doors, but one day Mr. Jackson suddenly found that there is a printed rolling door device on the market, but their company The type of the printing machine is different and cannot be printed. So Mr. Jackson decided to order a rolling shutter door forming machine with the popular flower print from our company to meet market demand and expand production.

The rolling shutter door forming machine provided by our company not only guarantee the quality, but also have a comprehensive service system.

We will teach our customers how to use rolling shutter door forming machine and how to connect products. And we will provide detailed machines. Of course this is the difference between us and others.

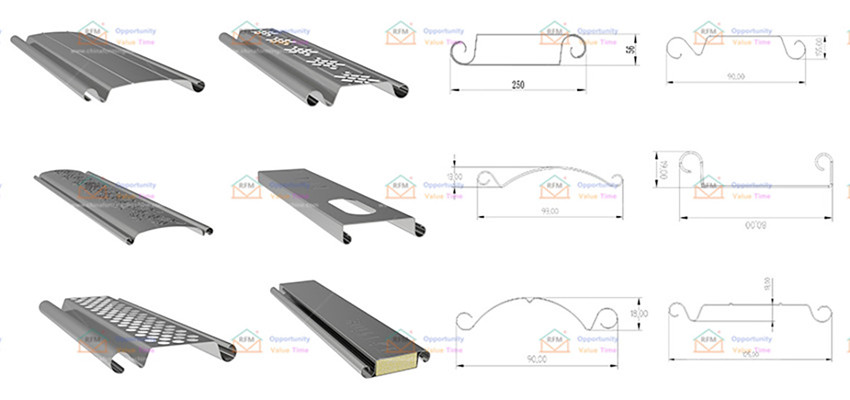

Application Range & Scene

|

No.

|

rolling shutter door forming machine

|

|

|

1

|

Suitable to process

|

Color alu-zinc steel strips

|

|

2

|

Roller

|

12Rows plus leveling device

|

|

3

|

Dimensions

|

5.4*1*1.5m

|

|

4

|

Motor Power

|

3Kw

|

|

5

|

Pump Station Motor

|

3Kw.Lichao Brand

|

|

6

|

Thickness of the plate

|

0.6-1.0mm

|

|

7

|

Productivity

|

10-15m/min

|

|

8

|

Material of the cutting blade

|

Cr12,Quenched treatment 58℃-60℃

|

|

9

|

Diameter of the roller

|

Φ50mm

|

|

10

|

Weight

|

About 2600kgs

|

|

11

|

Main structure of the machine

|

Square steel frame

|

|

12

|

Processing precision

|

Within 1.0mm

|

|

13

|

Side panel of machine

|

16mm

|

|

14

|

Chain Wheel and Cycle Chain

|

1 Inch

|

|

15

|

Voltage

|

380V 50Hz 3phases or as customer’s need

|

|

16

|

Control system

|

PLC control (Delta)

|

|

17

|

Frequency system

|

Delta

|

|

18

|

Drive mode

|

Gear driver

|

|

19

|

Touch screen

|

Delta

|

|

20

|

Rolling materials

|

45# forging steel with chromium plate

|

|

21

|

Length Tolerance

|

±2mm

|

rolling shutter door forming machine Provide Installation Method & Customized Profile For Free

Professional Inspection Process

rolling shutter door forming machine Customers’ Application Projects

Inspection/Package/Delivery

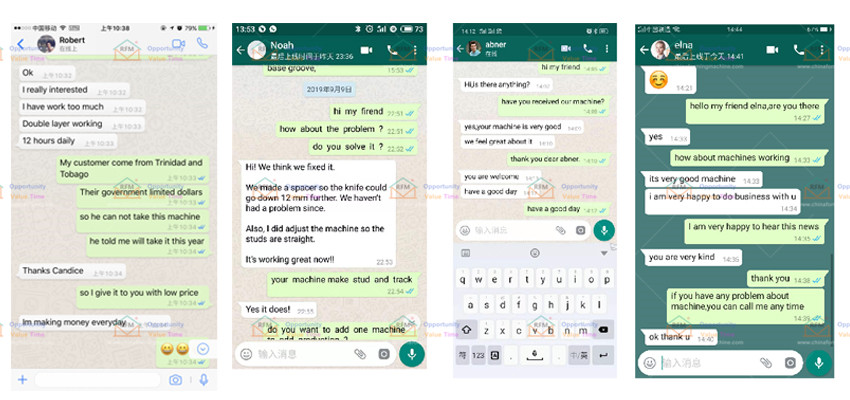

Customer Feedback

FAQ

Q1. How do I choose the right machine for me?

1. A machine doesn’t just provide a few photos to prove what they can produce

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You don’t show the product I need, can you manufacture it?

Our company’s engineers have studied in well-known European cold bending companies and have great advantages in machine design and R&D and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 40 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate, and have a longer service life.

The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, 26 years of production experience, to be a service company that you have the strength to guarantee

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don’t have your own outline drawing, we can recommend some models according to your local market standard.

For more great product videos visit our YouTube