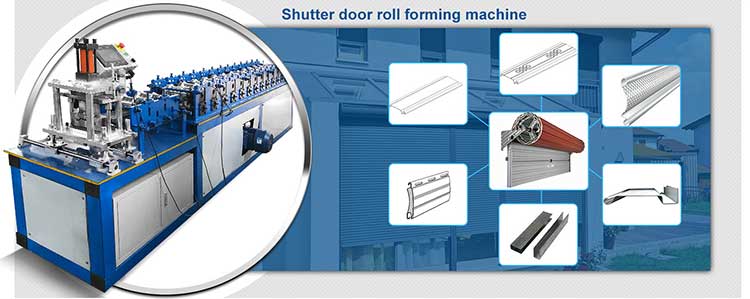

2022 Hot selling Rolling door forming machine

Sometimes the roller shutter door may fail unexpectedly, endangering our workers.Under normal operation, the roller shutter door runs smoothly, so that most workers may not realize the danger that the faulty door may bring.

Are you and your workers aware that the weight of your commercial garage door or industrial door can easily exceed half a ton? Take a moment to analyze the potential danger if one of your roller shutter doors fails, it may fall and hit one of your workers.

Most commercial doors and industrial doors do not have automatic reverse function, such as “commercial operator bottom sensor”. These sensors stop and flip the door when they touch an obstacle (such as a person or object).Here are some simple examples to illustrate that if your door is not properly maintained, problems may occur:The drive sprocket may disengage from the shaft, allowing the door to fall freely and close.When the door rises from the top of the frame, the drive chain may jump out of the sprocket, allowing the door to fall freely and close.

When the door is opened, the chain may break, allowing the door to fall freely and close. At the same time, the chain may also fall on the floor, causing a second danger.Without proper maintenance, sometimes the door’s motor can continue to work even after the door is fully opened or closed.It is important to arrange regular inspections and maintenance, and have sufficient funds to support your preventive maintenance plan and workers’ constant crisis awareness.

We can provide easy-maintaining Rolling door forming machine. We not only produce equipment, we also understand how the roller shutter doors are used. When we produce Rolling door forming machine, we can avoid the problems you encounter when using curtain sheets, and provide you with a more favorable market expansion.

Application Range & Scene

Rolling door forming machine

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

FAQ

Q1. How do I choose the right machine for me?

1. A machine doesn’t just provide a few photos to prove what they can produce

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You don’t show the product I need, can you manufacture it?

Our company’s engineers have studied in well-known European cold bending companies and have great advantages in machine design and R&D and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 40 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate, and have a longer service life.

The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, 26 years of production experience, to be a service company that you have the strength to guarantee

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don’t have your own outline drawing, we can recommend some models according to your local market standard.