How to maintenance the roller shutter door machine rollers?

The reasonable machine maintenance can make it create more profit for customers, so now we will introduce the machine maintenance for everybody.

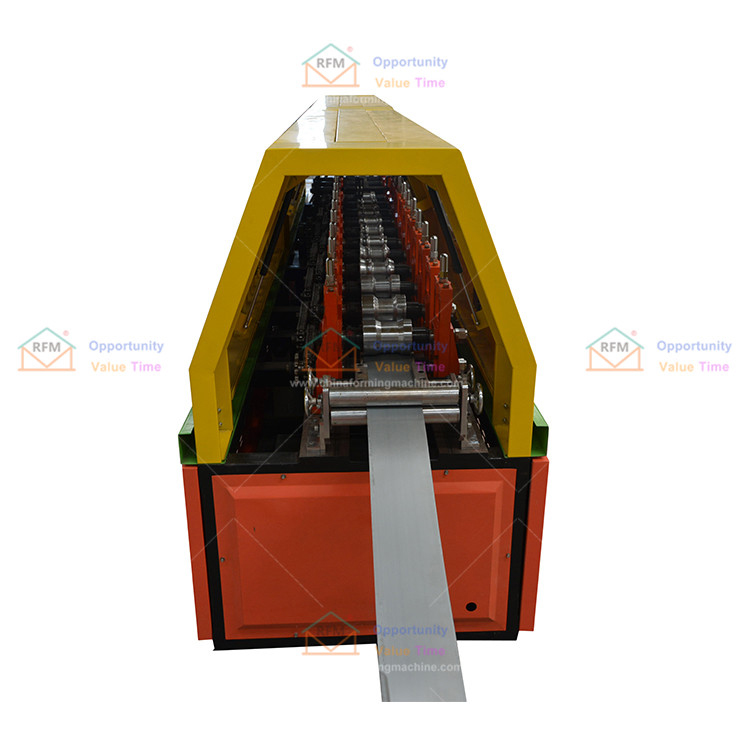

The rollers in the equipment should always be kept clean. The best way to clean the rollers is by spraying them using a spray cleaner and letting the rolling shutter door machine run empty for a number of minutes. After this, unplug the machine and wipe the rollers with a clean towel. Repeat the process until all the rollers are clean. Cleaning the rollers saves you time and energy to wipe or clean long stretches of the material that you have cut.

Chains should be well lubricated to prevent your blades from getting stuck when working. Cleaning the machine allows you to spot any areas that require repairs or replacements. Roll forming machinery should be serviced regularly depending on the frequency of use. Some parts of the machines such as rollers require more frequent cleaning. With the right maintenance procedures, you ensure longevity and durability in all your equipment.

About the machine maintenance, we also prepared the clear maintenance list for each our customers, which cover all modular part of the machine, but don’t worry dear,we will not increase the rolling shutter machine price. so please contact us if you are interested in it, will share more detail information about it.

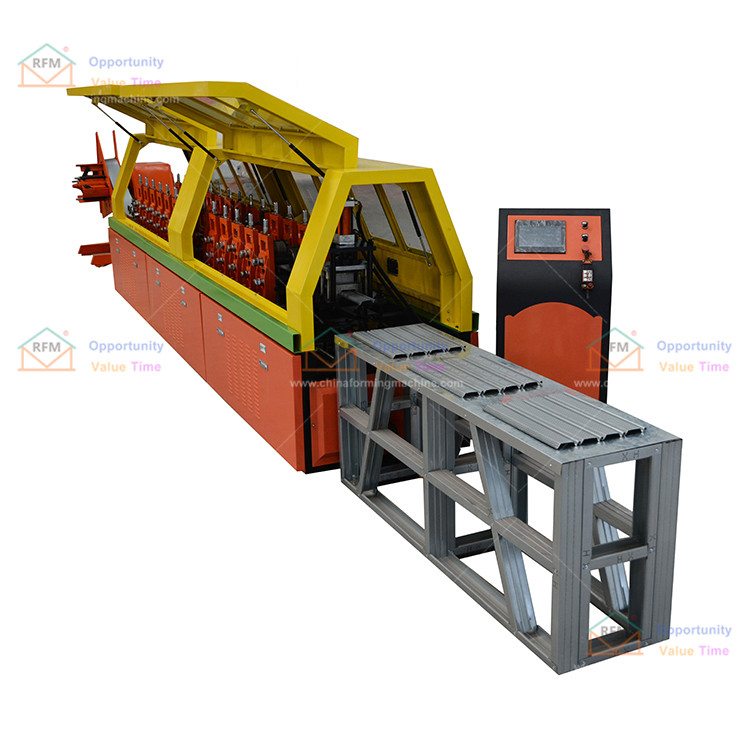

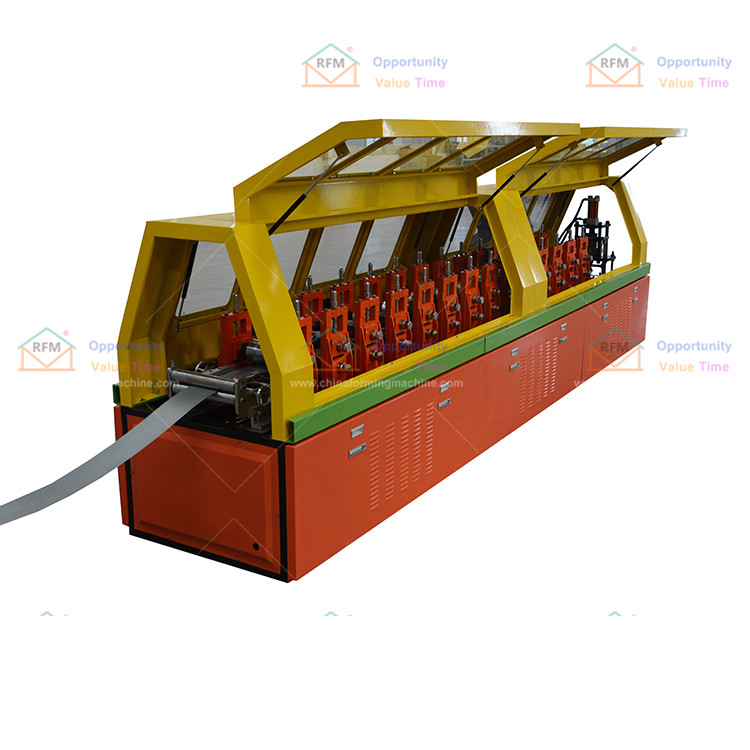

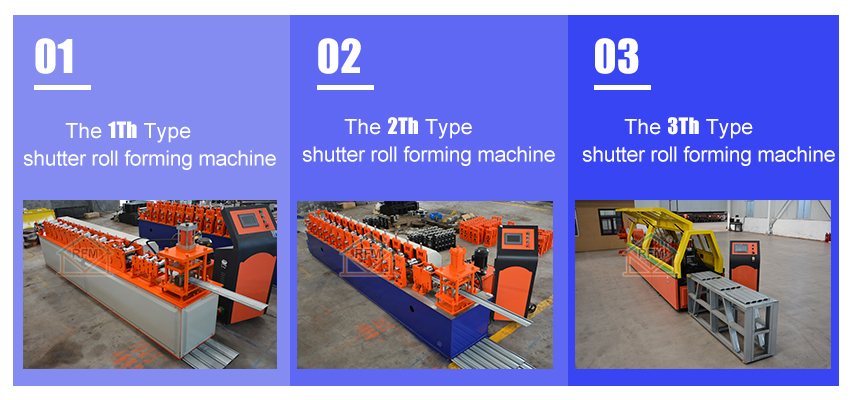

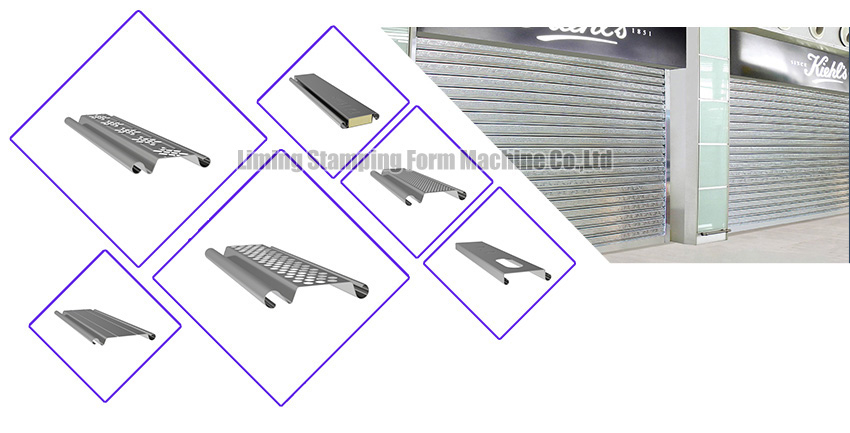

—3 machine configurations for you to choose—

—shutter roll forming machine—

| No. | Item | Specification |

| 1 | Can Formed Material | GI,AI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 50Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 0.6-1.0mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 4500mmx900mmx1300mm |

| 8 | Speed | 10-20m/min |

| 9 | Diameter of shaft | 40mm |

| 10 | Weight of the Machine | 2500KGS |

| 11 | Material of rollers | Cr12 |

| 12 | Motor brand | Siemens or Guomao |

| 13 | PLC | Siemens or Delta or Mitsubushi |

| 14 | Total power(kw) | 8kw |

| 15 | Power of hydraulic system | 4kw |

| 16 | Power of main molding core | 4kw |