Mr. Paula from Dominia is a profile wholesaler. He used to purchase steel profiles in China and then retail. Later, as the scale expanded, he also wanted to reduce costs, so he wanted to purchase machines. Because the furring channel keel profiles are widely welcomed, I have always wanted to purchase a furring channel roll forming machine

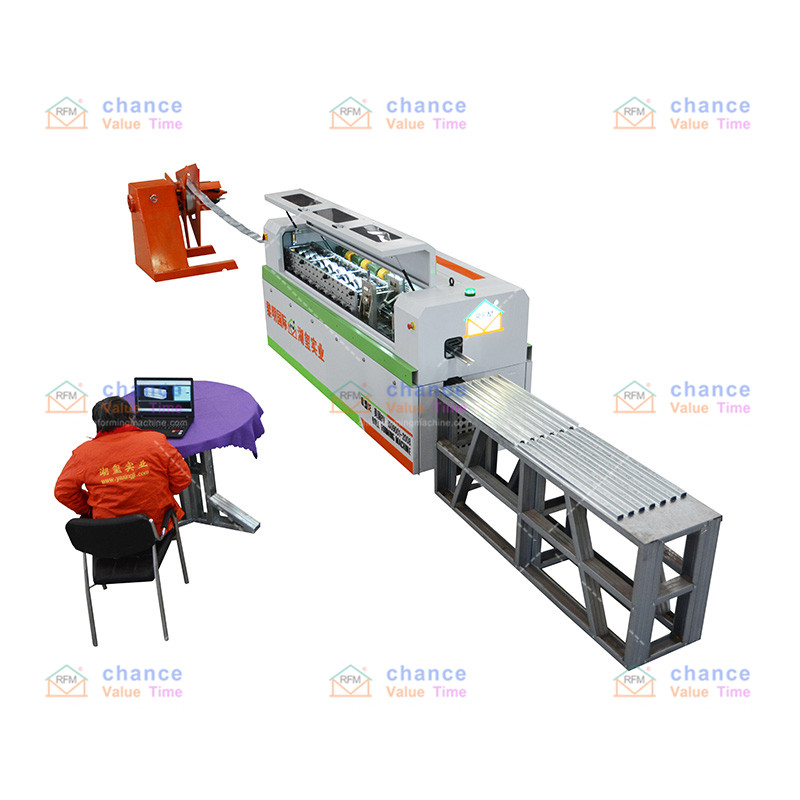

We provide reliable furring channel roll forming machines. Our machines will go through various quality inspections, and go through 5 major quality inspection processes, namely production quality inspection, trial run quality inspection, assembly quality inspection, quality inspection before delivery, and raw material quality inspection. We have a professional quality inspection team, and each quality inspection link has a dedicated person responsible for testing the quality of the machine after production is completed to ensure that the quality of our machine meets the standard. Test run inspection to ensure that the final product produced by our machine is flawless, and the machine structure is adjusted according to customer needs.

Our roller stand design is our patented technology, which is made of cast steel and is cast in one piece. It is not welded, so the structure is more stable. In addition, the toughness of cast steel is better. During the machine’s rapid and long-term operation, the machine is very easy to generate heat, so the torii will be very easily deformed. Cast steel has good toughness and can be restored to its original state in a short time. Our machines can keep running for a long time for 24 hours to increase the daily output of customers.immediately. Avoid unnecessary losses of Mr. Paula.

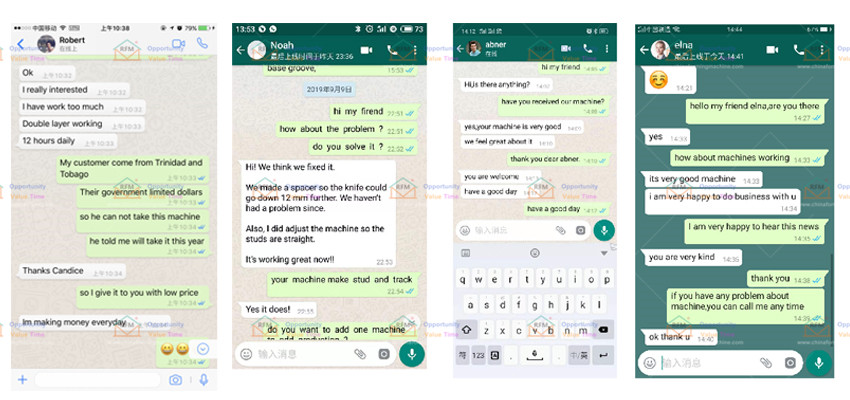

Mr. Paula is very satisfied with my machines, we get a glad cooperation.

Roll forming machine Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery