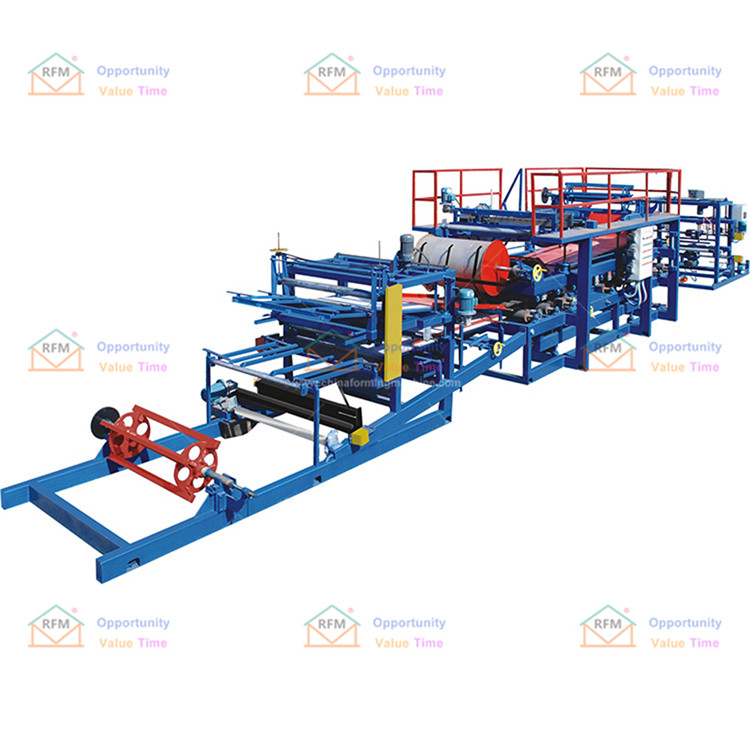

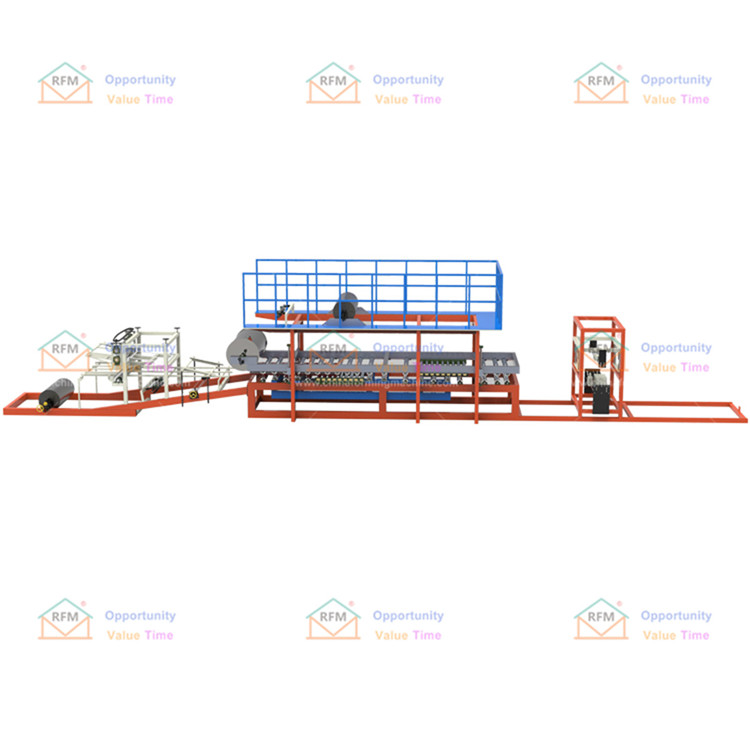

The PU sandwich board has good fire and moisture resistance, and is also commonly used in the edge banding core material of other material composite boards. The polyurethane edge banding composite board uses high-quality color-coated steel plate as the surface material, which is cured by high-pressure foaming and is traditionally linked to traditional cotton maintenance materials. Compared with fire prevention and heat preservation effect, the performance is longer, the installation is convenient and the appearance is elegant. It is a leader in steel construction maintenance materials.It is a high-strength, energy-saving and environmentally friendly building board.Mr. Green from the UK plans to invest in a composite board production line, but he has no production experience and the factory area is not large. Generally speaking, the length of the composite board production line is about 120 meters.

We calculated the machine layout for Mr. Green and arranged the production layout for him reasonably. It shortens the distance between the production raw materials and the machine, shortens the distance between the machine and the collecting platform, and shortens the distance between the collecting platform and the loading vehicle. There is enough space for workers to move around, and at the same time, an emergency passage is reserved.Green is very satisfied with our service!

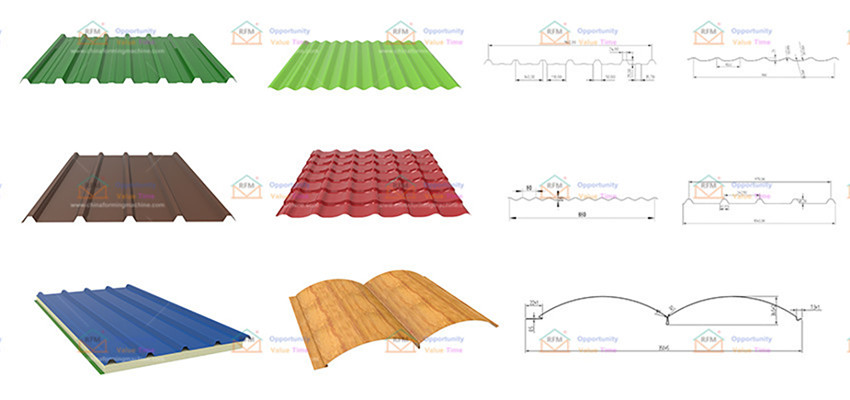

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

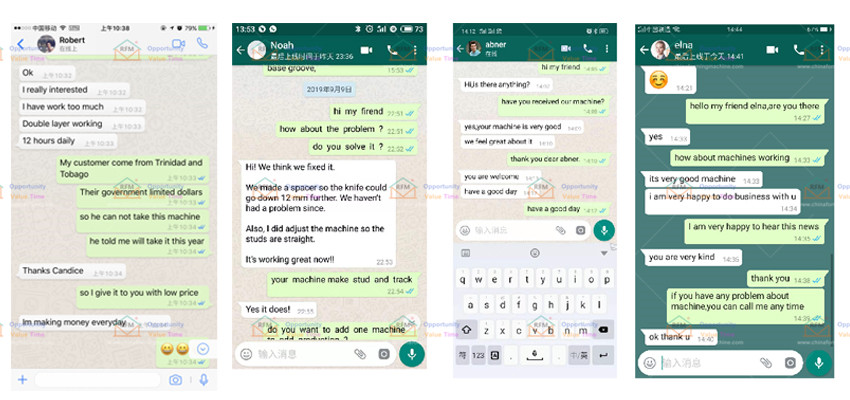

Customer Feedback