-

No. 8 of No.3 Road, Industrial Zone, Botou City, Hebei Province, China.

What is the slitting cutting machine?

1. What Is a Slitting Cutting Machine?

A slitting cutting machine, also called a slitting machine or strip cutting machine, cuts cold-rolled steel, stainless steel, aluminum, and other metal coils into narrow strips.

After cutting, the strips are rewound into smaller coils for the next production process.

Industries such as profile processing, hardware manufacturing, transformers, and motors rely on slitting machines for precision cutting of metal strips.

2. How to Judge If Your Industry Needs Slitting Lines

If your production line requires narrow strips from large metal coils or demands high precision ±0.1 mm, a slitting cutting machine is essential.

Key indicators include:

-

Material type (steel, aluminum, stainless steel, copper)

-

Desired strip width and length

-

Volume and speed requirements

3. How to Purchase a Slitting Line Based on Workshop Area

Before buying, consider:

-

Workshop space and layout

-

Operator availability

-

Coil loading/unloading paths

-

Future expansion possibilities

By planning the installation area, you can maximize efficiency and safety.

4. Materials Suitable for Slitting Lines

Slitting machines can handle:

-

Galvanized steel

-

Stainless steel

-

Aluminum

-

Copper and other metal strips

This versatility ensures your line can adapt to different production needs.

5. Cutting Speed and Operation

Modern slitting lines offer high-speed operation:

-

Continuous feeding of metal coils

-

Slitting accuracy within ±0.1 mm

-

Adjustable speeds depending on material thickness

PLC systems control the feeding, slitting, and recoiling automatically, ensuring consistent quality and minimal waste.

6. When to Use a Waste Collection Device

Waste collection devices are essential when cutting metals that produce edges or trimming scraps.

They improve workplace cleanliness, reduce material loss, and facilitate recycling.

7. Why Some Slitting Lines Dig in the Ground

Some high-speed slitting lines use underground pit installation for the recoiler and decoiler.

This design:

-

Reduces operator strain

-

Stabilizes coil feeding

-

Prevents material deviation at high speeds

8. Key Parameters

-

Number of operators: 1–2

-

Coil width: up to 1250 mm

-

Maximum thickness: 0.3–2.5 mm

-

Cutting method: rotary knives

-

Blade material: hardened steel

-

Size change: adjustable via PLC

-

Error range: ±0.1 mm

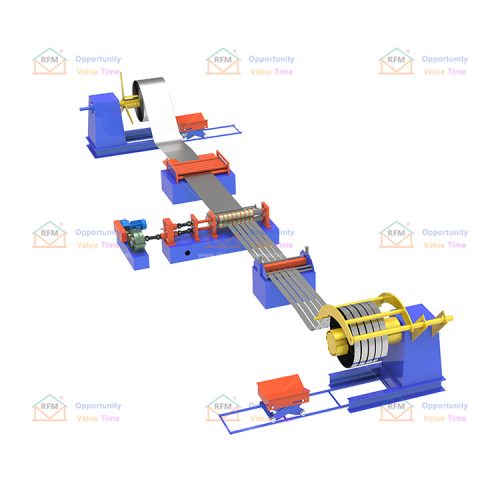

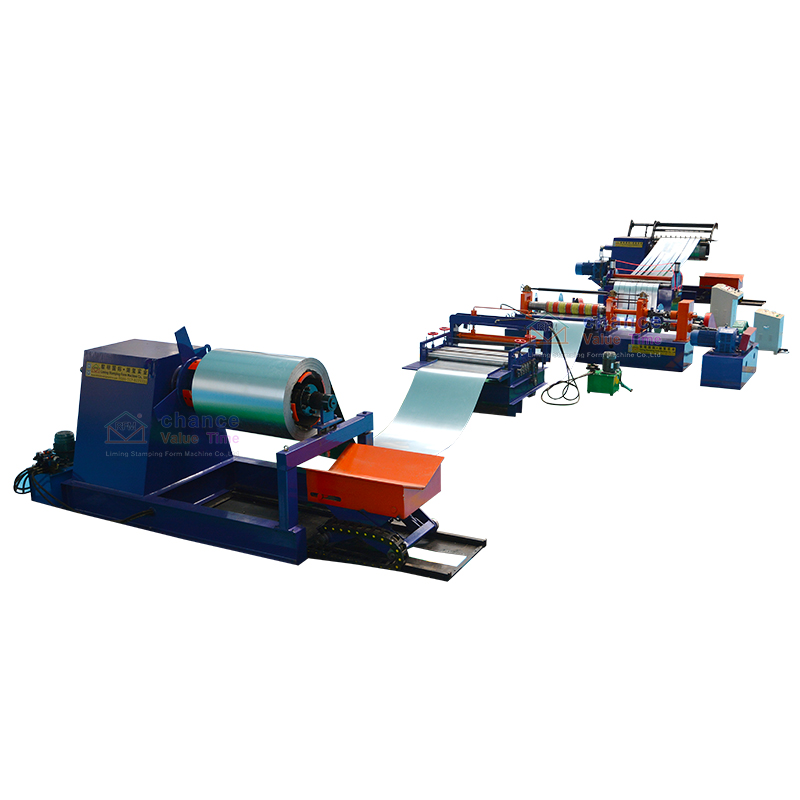

9. How It Works

-

Uncoiling: Load the steel coil onto the decoiler.

-

Slitting: The sheet passes through rotary knives to cut into narrow strips.

-

Recoiling: Slit strips rewind into smaller coils ready for the next process.

10. High-Quality Slitting Line Components

-

Hydraulic decoiler & recoiler

-

Precision slitting heads

-

Looping or tension control system

-

PLC automatic control panel

11. Main Advantages

✅ High Accuracy: Cuts metal within ±0.1 mm tolerance

✅ Versatility: Handles steel, aluminum, stainless steel, and copper

✅ Efficiency: Continuous operation saves time and material

✅ Automation: PLC ensures steady operation and easy setup

✅ Clean Edges: Reduces burrs and material waste

12. Applications

Slitting cutting machines serve multiple industries:

-

Metal roofing sheet & wall panel production

-

C/Z purlin and stud & track roll forming lines

-

Electrical cabinet and door frame manufacturing

-

Automotive and HVAC ducts

13. Why Choose Hebei Liming Stamping Form Machine Co., Ltd.?

With nearly 30 years of experience, Hebei Liming customizes slitting lines for materials up to 2.5 mm thickness and 1250 mm width.

Our lines deliver:

-

High precision

-

Smooth operation

-

Long service life

-

Full installation & technical support

For more great product videos visit our YouTube