-

No. 8 of No.3 Road, Industrial Zone, Botou City, Hebei Province, China.

What is stud and track roll forming machine?

What is stud and track roll forming machine?

1. What Is a Stud and Track Roll Forming Machine?

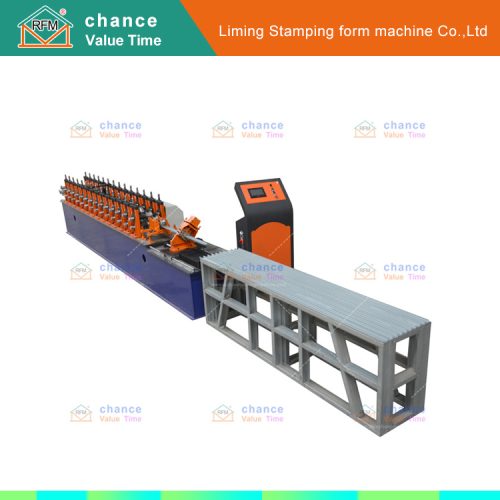

The LIMING Stud and Track Roll Forming Machine forms steel strips into complex cross-section profiles for walls, ceilings, corners, and partitions.

It produces light steel keels, painted keels, cassette keels, and C/U/L-shaped profiles.

The machine uses continuous cold rolling technology. The PLC-controlled system ensures fast size changes and stable quality.

2. Classification of Stud and Track

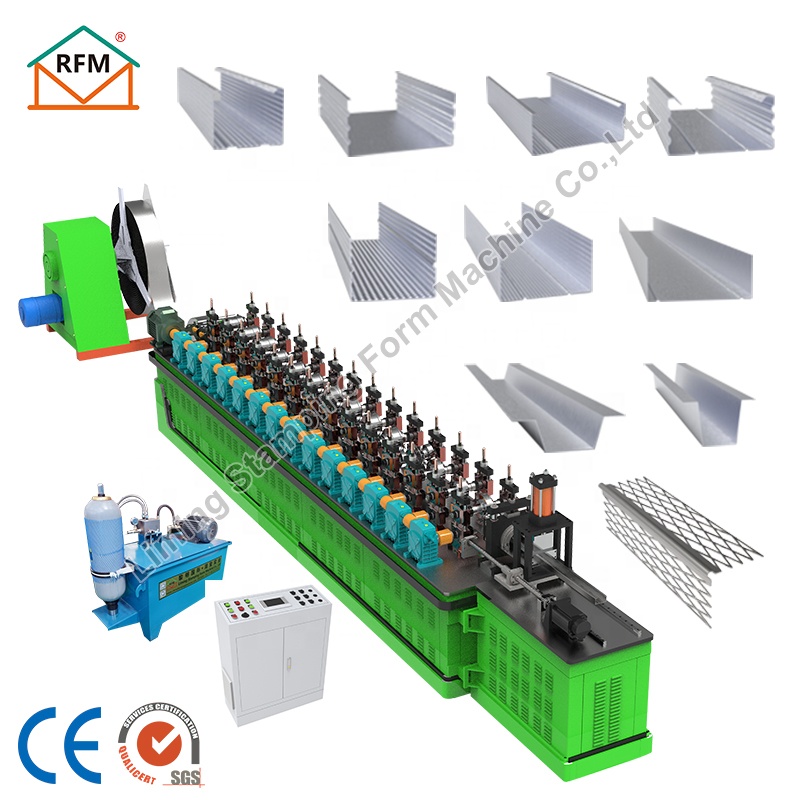

Studs and tracks come in different shapes and sizes:

-

C-shaped profiles – for wall studs and partitions

-

U-shaped tracks – for ceiling or wall top/bottom tracks

-

L-shaped corners – for wall edges or frame corners

-

Cassette keels – for ceilings and modular systems

Each profile is compatible with different steel thicknesses and coatings, such as galvanized or painted steel.

3. Stud and Track Roll Forming Machine Structure

-

Flying Shear Cutting: Produces precision-tolerance parts at high speed.

-

Adjustable Roll Forming Line: Change the profile size within 1 minute via PLC without replacing tools or gaskets.

-

High-Speed Production: Maximum forming speed up to 150 meters per minute.

-

PLC-Controlled Punching and Bending: Ensures accurate holes for electrical wiring or fasteners.

-

Heavy-Duty Steel Frame: Maintains stability during high-speed operation.

4. How Does the Machine Work?

-

Material Loading: Coil steel is loaded onto the decoiler.

-

Roll Forming: Steel passes through consecutive rollers that shape it into C, U, or L profiles.

-

Punching & Cutting: The machine punches holes and cuts the profile to the desired length.

-

Output: Finished studs and tracks are stacked for packaging or assembly.

The process is fully automated, reducing labor and increasing efficiency.

5. How to Choose the Right Machine

-

Profile Requirements: Identify the C/U/L sizes and wall/ceiling specifications.

-

Production Speed: Consider daily output requirements.

-

Material Compatibility: Check thickness and coating types.

-

Automation Level: PLC control and automatic tooling adjustment reduce downtime.

-

After-Sales Service: Ensure installation, training, and spare parts are provided.

The machine is divided into:

stud roll forming machine

track roll forming machine

omega keel roll forming machine

Ceiling T grid roll forming machine

Metal steel wall bead corner corner roll forming machine

3.How does the stud and track roll forming machine work?

The stud and track roll forming machine can be divided into:

Ordinary 20m/min roll forming machine

50m/min roll forming machine

100m/min roll forming machine

Adjustable size roll forming machine (please contact us if necessary)

4.How do I choose the roll forming machine that suits me?

If you have these problems, we can provide you with solutions

1. I don’t know the product, I have been recommended by someone, and want to start a business (recommended version, which can provide some popular products in the market. Can provide investigation and analysis services)

2. We are a distributor of machines and want to find more high-quality products

3. I am a machine retailer and do not have my own machine, but I have certain product knowledge, but I need to recommend the machine

4. I am a middleman who wants to sell machines, but I don’t know how to choose?

We can provide machine solutions for machine manufacturers, import profile traders, construction project companies, etc.

6. LIMING Company Introduction

LIMING specializes in roll forming machines for 29+ years.

-

CE/ISO certified machines

-

Customizable stud and track lines

-

Global installation experience: Europe, Africa, South America, Middle East

-

Complete technical support, including PLC programming, installation, and training

Our machines help clients produce high-precision LGS profiles efficiently, supporting residential and commercial construction projects.