-

No. 8 of No.3 Road, Industrial Zone, Botou City, Hebei Province, China.

Roof Panel Roll Forming Machine | Automatic Roofing Sheet Making Line

Roof Panel Roll Forming Machine | Automatic Roofing Sheet Making Line

In the modern construction industry, metal roofing has become a global trend due to its durability, weather resistance, and modern appearance. A roof panel roll forming machine plays a crucial role in producing high-quality metal roofing sheets efficiently and consistently.

What Is a Roof Panel Roll Forming Machine?

A roof panel roll forming machine is a fully automatic production line that converts metal coils—such as galvanized steel, pre-painted steel (PPGI), or aluminum—into customized roof sheet profiles. Through a continuous cold roll forming process, the steel passes through a series of precision rollers to achieve perfect shape and dimensions.

This technology ensures high accuracy, beautiful surface quality, and minimal material waste—ideal for roofing manufacturers, steel structure builders, and construction contractors.

Roof Roll Forming Machine Overview

The roof roll forming machine is a professional production line designed for manufacturing metal roof sheets used in industrial, commercial, and residential construction.

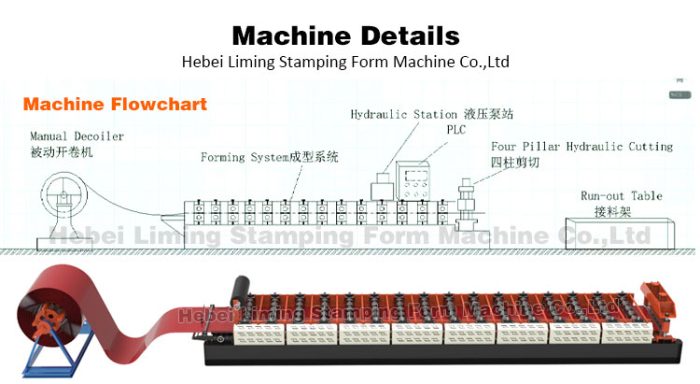

It integrates decoiling, guiding, forming, cutting, and stacking into one automated process.

With PLC control, accurate cutting, and stable performance, this line ensures high-speed and cost-effective roofing production.

👉 Get a Free Quote for Your Roof Machine

Main Features of the Roofing Sheet Forming Line

-

⚙️ High precision rollers – Made of GCr15 with chrome coating for durability.

-

💡 Automatic control – PLC + touchscreen for smart operation.

-

🔧 Hydraulic cutting – Burr-free and precise length cutting.

-

🧱 Custom roof profile design – Available for trapezoidal, corrugated, or tile sheets.

-

🚀 Stable structure – Heavy-duty frame and gearbox drive system.

-

🔄 Optional units – Decoiler, stacker, punching, or embossing modules.

Technical Specifications

| Item | Description |

|---|---|

| Material | Galvanized or pre-painted steel |

| Thickness | 0.3–0.8 mm |

| Effective width | 840–1250 mm |

| Forming speed | 10–25 m/min |

| Rollers | GCr15 with hard chrome |

| Drive | Chain or gearbox |

| Cutting | Hydraulic system |

| Power | 7.5–15 kW |

Roof Sheet Profiles

We can produce a wide range of metal roofing panels, including:

-

Trapezoidal roof sheets

-

Corrugated panels

-

Step tile roofing sheets

-

Standing seam roofing panels

Applications

Roof panel roll forming machines are widely used in:

-

Steel structure buildings

-

Residential roofing

-

Industrial workshops

-

Agricultural warehouses

-

Prefabricated building projects

These metal roofing sheets are durable, waterproof, and aesthetic, making them ideal for modern construction.

Production Process

-

Decoiling – Uncoil galvanized or color steel coil

-

Feeding & Guiding – Ensure straight material entry

-

Roll Forming – Step-by-step forming to the desired roof profile

-

Cutting – Hydraulic cutting to set length

-

Stacking – Automatic collection of finished sheets

Advantages of Our Roof Panel Forming Line

-

29+ years of roll forming machine manufacturing experience

-

CE & ISO certified equipment

-

Custom design for local roof profiles

-

Fast installation and operator training

-

Lifetime technical support and spare parts supply

-

Exported to 100+ countries (Europe, Africa, South America, Asia)

Customer Case

🎥 Video title: “Automatic Roof Panel Roll Forming Machine in Operation”

Case Example:

A Peruvian client ordered a 1220mm roof panel forming line with trapezoidal and corrugated designs. The line achieved smooth forming and stable production, producing over 1200m² of roofing per day.

Related Machines

Get a Free Quote Now

Looking for a roof panel roll forming machine manufacturer with reliable performance and full technical support?

We provide customized solutions, installation guidance, and after-sales service worldwide.