-

No. 8 of No.3 Road, Industrial Zone, Botou City, Hebei Province, China.

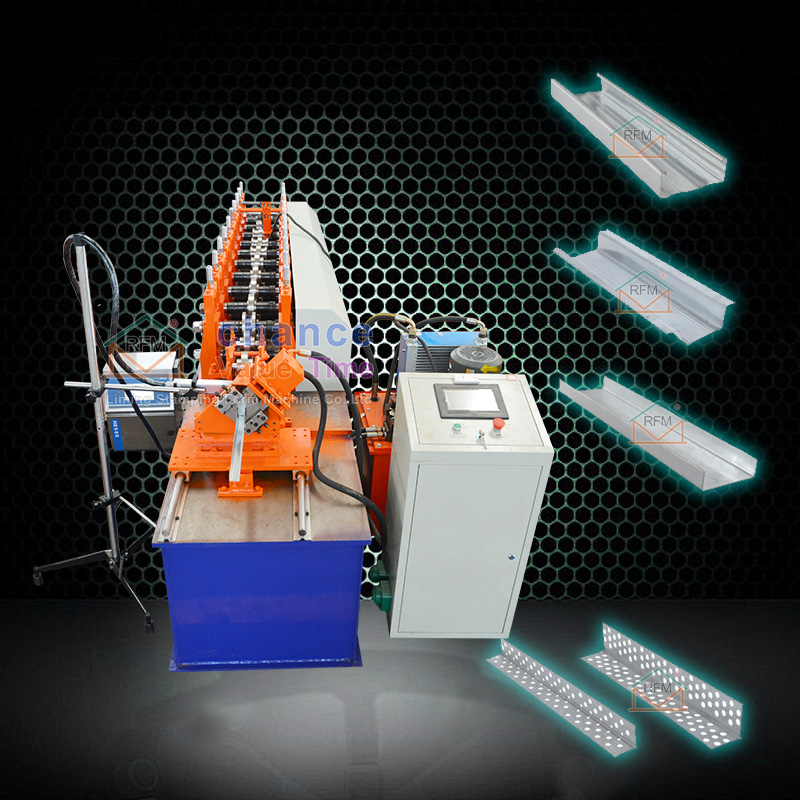

Omega Roll Forming Machine | Automatic Metal Channel Forming Line

Omega Roll Forming Machine | Automatic Metal Channel Forming Line

Omega Roll Forming Machine Overview

The Omega roll forming machine is specially designed for producing metal omega profiles, which are widely used in ceiling suspension systems, drywall partitions, and structural supports. This machine transforms galvanized steel or aluminum coils into omega-shaped channels with high precision and uniform dimensions.

Our automatic omega forming line combines uncoiling, feeding, punching, roll forming, and cutting into a single continuous process. It offers fast speed, stable performance, and flexible adjustment for different thicknesses and sizes.

Main Features

-

High Precision Rollers

All rollers are made from high-grade steel, CNC machined, and hard chrome-plated to ensure smooth forming and long life. -

PLC Control System

Equipped with a PLC control unit and touch screen interface, enabling automatic length setting, counting, and easy operation. -

Heavy-Duty Structure

The frame adopts welded steel construction, providing strong rigidity and vibration resistance during continuous production. -

Efficient Cutting System

Hydraulic cutting ensures accurate length and burr-free edges. -

Energy Saving Design

Low power consumption and low noise for eco-friendly production.

Technical Specifications

| Item | Specification |

|---|---|

| Material | Galvanized Steel, Aluminum, Stainless Steel |

| Thickness | 0.3–1.2 mm |

| Coil Width | 100–300 mm |

| Forming Speed | 20–30 m/min |

| Roller Stations | 10–14 |

| Drive Type | Chain or Gearbox |

| Control System | PLC (Siemens/Delta/Omron) |

| Cutting System | Hydraulic Post-Cutting |

Applications

The omega profile produced by this machine is commonly used in:

-

Ceiling suspension grids

-

Drywall and partition frame systems

-

Wall cladding substructures

-

Solar mounting and support channels

These profiles offer lightweight structure, high strength, and excellent corrosion resistance.

Why Choose Hebei Liming?

As a leading roll forming machine manufacturer since 1996, Hebei Liming Stamping Form Machine Co., Ltd. provides complete omega profile forming solutions with precision engineering and fast delivery.

We offer:

-

3D profile design and layout customization

-

CE & ISO certified production lines

-

Free machine testing before delivery

-

On-site installation and operator training

-

Lifetime technical support and spare parts service

More options for profile machines

Call to Action

👉 Get your customized Omega Roll Forming Machine now!

Contact us for a free quote and production layout design.

📧 Email: admin@chinaformingmachine.com

🌐 Website: www.chinaformingmachine.com