-

No. 8 of No.3 Road, Industrial Zone, Botou City, Hebei Province, China.

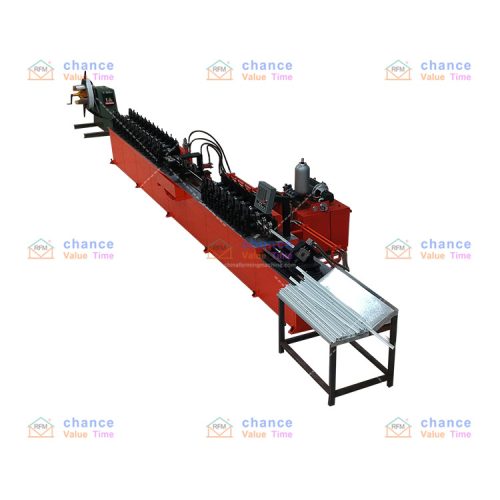

Metal Corner Angle Bead Forming Machine | Automatic Drywall Corner Production Line

In modern construction, metal corner beads play a key role in protecting wall corners and achieving a clean, smooth finish. A metal corner angle bead forming machine is the essential equipment for producing high-quality drywall corner beads efficiently and automatically.

What Is a Metal Corner Angle Bead Forming Machine?

The metal corner angle bead forming machine is a precision roll forming line designed to produce galvanized steel or stainless-steel corner beads used in drywall and plasterboard installation.

It feeds raw coil material through a series of rollers to form accurate angles with punched holes for better plaster bonding. The final products are straight, smooth, and corrosion-resistant — perfect for interior wall protection.

Main Features

-

High Precision Rollers: Hardened and CNC-machined to ensure consistent angle shape.

-

Automatic Control System: PLC + touch screen control for easy operation and accurate length cutting.

-

Servo Flying Cutter: Ensures fast and burr-free cutting without stopping the machine.

-

Durable Structure: Heavy-duty welded frame for vibration-free and stable production.

-

Hole Punching Integration: Optional punching system to create uniform plaster bonding holes.

Technical Parameters

| Item | Specification |

|---|---|

| Material | Galvanized Steel, Aluminum, Stainless Steel |

| Thickness | 0.3–0.6 mm |

| Forming Speed | 30–60 m/min |

| Roller Stations | 12–16 |

| Control System | PLC + Touch Screen |

| Cutting Type | Servo / Hydraulic |

| Power | 5.5–11 kW |

Applications

The corner bead produced by this machine is widely used for:

-

Drywall corner protection

-

Plasterboard edge finishing

-

Interior decoration and renovation projects

-

Building and construction industry

Advantages of Liming Metal Corner Bead Machine

✅ 29 years of experience in roll forming technology

✅ High-speed production line up to 60m/min

✅ Customizable designs for various bead types (angle, bullnose, wing type)

✅ Easy operation with automatic cutting and stacking options

✅ Global after-sales service and on-site installation support

Our machines are widely exported to Europe, South America, the Middle East, and Africa, gaining strong customer satisfaction in the drywall construction industry.

Production Line Composition

-

Decoiler – Feeds coil material automatically

-

Leveling System – Straightens the coil before forming

-

Roll Forming System – Shapes the metal into corner bead profile

-

Punching System – Creates uniform holes (optional)

-

Cutting System – Automatically cuts to preset lengths

-

Output Table – Collects finished products neatly

Contact Us

Looking for a reliable metal corner angle bead forming machine manufacturer?

📩 Contact us today to get a customized solution for your drywall corner production line!