-

No. 8 of No.3 Road, Industrial Zone, Botou City, Hebei Province, China.

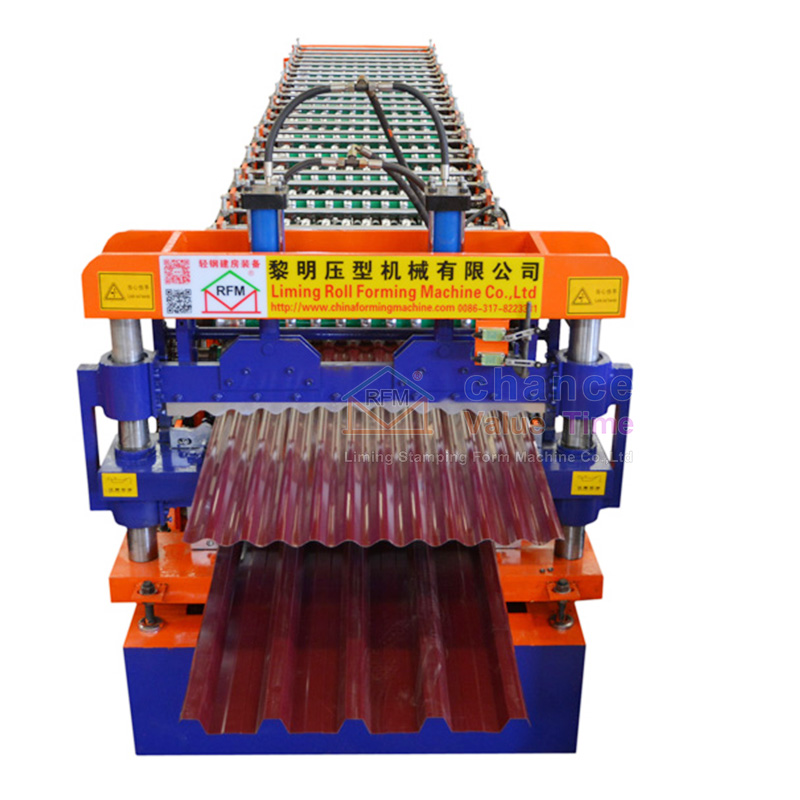

Double Layer Roof Panel Forming Machine | Two Layer Roofing Sheet Roll Forming Line

Double Layer Roof Panel Forming Machine Overview

The double layer roof panel forming machine is an innovative roll forming line designed to produce two different roof sheet profiles on one machine. With a compact structure and automatic control system, it saves both space and cost while ensuring high production efficiency.

This two-in-one roll forming line can quickly switch between corrugated roof sheets, trapezoidal panels, and step tile designs. It is widely used in metal roofing, wall cladding, and building construction industries.

Main Features

-

⚙️ Two profiles in one machine – Produce two types of roofing sheets without changing rollers.

-

💡 Space-saving structure – Ideal for factories with limited space.

-

🔄 Automatic control system – PLC touch screen with automatic length setting and counting.

-

🔧 High precision forming – Rollers made of GCr15 with hard chrome coating for long durability.

-

🔋 Energy-saving hydraulic cutting – Smooth cutting, low noise, and minimal waste.

-

🧱 Optional decoiler & stacker – Improve automation level and production efficiency.

Technical Specifications

| Item | Description |

|---|---|

| Material | Galvanized steel, pre-painted steel, aluminum |

| Thickness | 0.3–0.8 mm |

| Effective width | 840–1250 mm |

| Forming speed | 8–15 m/min |

| Roller material | GCr15 with hard chrome |

| Drive system | Chain or gearbox |

| Cutting system | Hydraulic cutting |

| Control system | PLC with touch screen |

| Power | 7.5–15 kW |

| Layers | Upper and lower roll forming lines |

Production Process

-

Decoiling – Feeding galvanized steel or color steel coil.

-

Forming (Upper layer) – Produces roof panel A (e.g., trapezoidal sheet).

-

Forming (Lower layer) – Produces roof panel B (e.g., corrugated or tile sheet).

-

Cutting – Hydraulic cutting system ensures precise length.

-

Stacking – Finished products automatically collected.

(Recommended image: machine photo showing two forming layers, filename: double-layer-roof-forming-machine.jpg, alt text: “Double Layer Roof Sheet Roll Forming Machine Line”)

Applications

Double layer roofing sheet forming machines are widely used in:

-

Industrial workshops and warehouses

-

Residential roofing systems

-

Metal wall panels and siding

-

Prefabricated building structures

They provide strong, waterproof, and decorative metal panels suitable for modern construction.

Advantages of Our Double Layer Forming Line

-

Two different profiles in one machine — cost-effective design.

-

Compact frame, easy installation, and maintenance.

-

High-speed forming with smooth surface finish.

-

PLC system ensures automatic control and easy operation.

-

Customizable profile design according to your drawing or local market demand.

Video & Customer Cases

🎥 Video title: “Automatic Double Layer Roof Panel Roll Forming Line in Operation”

Project Example:

Our Brazilian customer purchased one double layer line for 0.45mm color steel sheets, producing corrugated and trapezoidal profiles. The machine achieved stable operation and accurate cutting, increasing output by 30%.

Related Machines

Get a Free Quote Now

Looking for a double layer roof panel forming machine to expand your metal roofing production?

We provide customized design, fast delivery, and lifetime technical support.