-

No. 8 of No.3 Road, Industrial Zone, Botou City, Hebei Province, China.

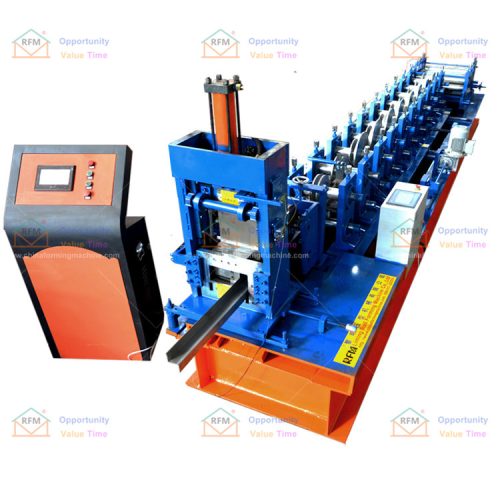

C Z Purlin Roll Forming Machine | High-Speed Steel Purlin Line

C Z Purlin Roll Forming Machine | High-Speed Steel Purlin Line

1. What Is a C Z Purlin Roll Forming Machine?

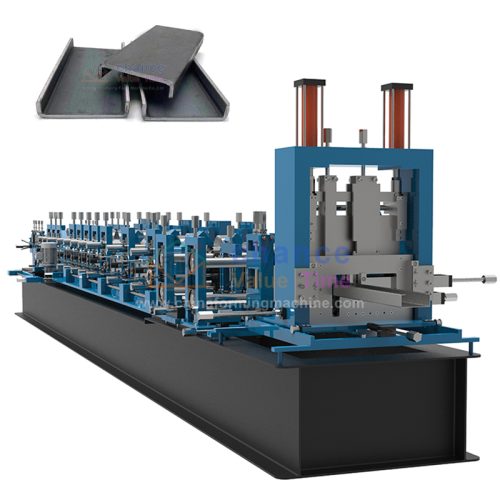

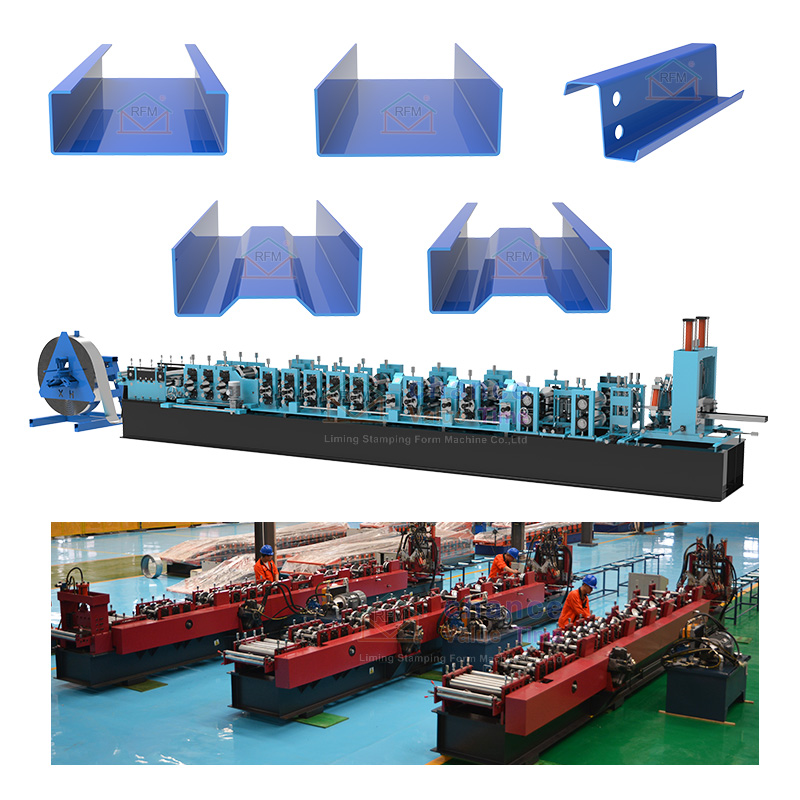

A C Z Purlin Roll Forming Machine forms C-shaped and Z-shaped steel purlins used in roof, wall, and floor framing for light steel structures.

The machine transforms galvanized or pre-painted steel coils into high-strength profiles for warehouses, workshops, commercial buildings, and residential constructions.

It ensures consistent quality, accurate dimensions, and efficient production for structural applications.

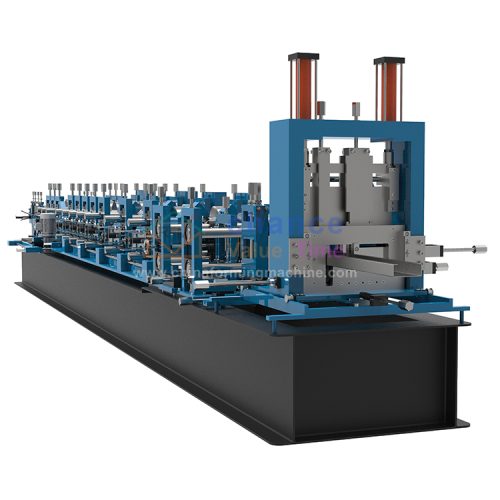

2. Machine Structure

-

Heavy-Duty Steel Frame: Ensures stability at high-speed operation.

-

PLC Control System: Adjusts purlin sizes quickly and automatically.

-

Roll Forming Stations: Sequential rollers shape steel into precise C or Z profiles.

-

Hydraulic Cutting System: Cuts purlins to specified lengths accurately.

-

Punching Unit (Optional): Creates holes for bolting and assembly.

3. How It Works

-

Decoiling: Load steel coils onto the hydraulic decoiler.

-

Roll Forming: Pass the steel through rollers to shape C or Z purlins.

-

Punching: Add bolt holes or slots if required.

-

Cutting: Hydraulic system cuts the purlin to length.

-

Output: Finished purlins stack for transportation or assembly.

The process is fully automated, reducing labor and improving production speed.

4. Applications of C/Z Purlins

C/Z purlins are widely used in:

-

Roof and wall framing for warehouses, factories, and workshops

-

Steel residential buildings and commercial projects

-

Light steel frame structures for agricultural or industrial use

-

Prefabricated buildings and modular construction

5. Main Advantages

✅ High Precision: Profiles meet strict structural standards

✅ Fast Production: Continuous forming speeds up to 20–25 m/min

✅ Versatility: Handles various steel thicknesses and coatings

✅ Automation: PLC system ensures consistent size and hole placement

✅ Cost-Effective: Reduces labor and material waste

6. Key Parameters

-

Material: Galvanized steel, color steel, or pre-painted steel

-

Thickness: 0.3–2.0 mm

-

Purlin Width: C/Z 50–300 mm

-

Forming Stations: 16–24

-

Main Power: 5.5–11 kW

-

Cutting: Hydraulic post-cutting

-

Control System: PLC with touch screen

-

Production Speed: 15–25 m/min

7. Why Choose Hebei Liming Stamping Form Machine Co., Ltd.?

-

Over 29 years of roll forming machine experience

-

CE/ISO certified machines

-

Customizable lines for C/Z purlins, stud & track, and roofing panels

-

Global installation experience: Europe, Africa, South America, Middle East

-

Full technical support including PLC programming, installation, and training

8. Get a Free Quote

Upgrade your steel framing production with our C Z Purlin Roll Forming Machine.

Reliable, automated, and high-speed solutions for structural steel projects.

| No. | Item | Specification |

| 1 | Can Formed Material | steel |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 1.5-3.0mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 9500mmx1200mmx1400mm |

| 8 | Speed | 0-20m/min |

| 9 | Diameter of shaft | 70mm |

| 10 | Weight of the Machine | 9000-12000KGS |