-

No. 8 of No.3 Road, Industrial Zone, Botou City, Hebei Province, China.

C Channel Purlin Forming Machine | Automatic Steel C Purlin Roll Forming Line Manufacturer

C Channel Purlin Forming Machine | Automatic Steel C Purlin Roll Forming Line Manufacturer

For steel structure house builders, the long service life of the C channel purlin forming machine is a very important concept.

I met a client from South Africa, Bestbuymetals, a manufacturer of building materials in the housing construction industry. He received a project to build a 2000 square meters steel structure workshop. Because C-shaped purlins are needed to build the house structure, only the C-channel purlins are in good shape and are not easily deformed in order to meet the quality standards and ensure their service life. In the past project, because the C-channel purlin molding process was immature, it could not meet his needs for long-life houses.

We provided him with a C channel purlin forming machine for building structure construction. Our raw materials are purchased from large domestic steel plants. Large domestic steel mills attach importance to quality and reputation, so they can ensure that the raw materials used to manufacture roller parts are steel and chromium, and they can meet the standards through quality inspections. Can meet the needs of quality standards.

Our molding process is designed by copra software and supported by data, which can ensure that the shape of the purlin is intact and not easily deformed during molding, and improve the service life of the C channel purlin molding machine.

Advantages of C channel purlin forming machine:

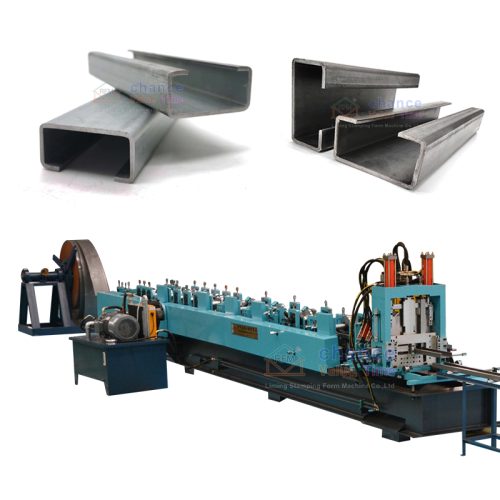

1. The forming thickness is large, the highest can reach 4mm

2. CZ purlin interchangeable model machines can be upgraded

3. Front shearing system, more accurate size, no waste

4. Bottom width can be adjusted

C channel purlin forming machine video

Later, Mr. Bestbuymetals continued to occupy the market share through the machines we provided and improved economic efficiency. We also became a happy partner.

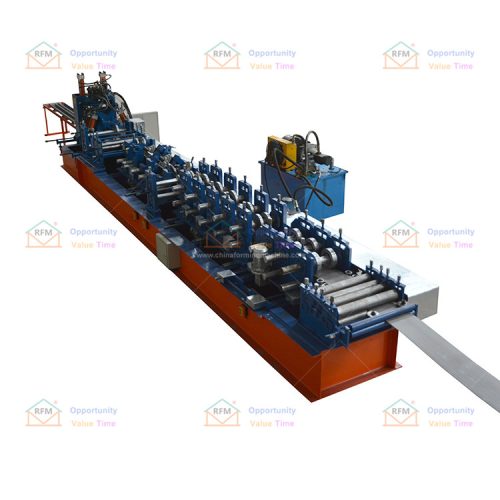

Channel Purlin Forming Machine Overview

The C channel purlin forming machine is a specialized roll forming equipment designed for producing high-quality C-shaped steel purlins used in steel structure buildings. This line integrates decoiling, leveling, forming, punching, cutting, and stacking into one automatic process. With high precision and efficiency, it’s ideal for light steel workshops, warehouses, and prefabricated construction projects.

The machine can produce multiple sizes of C purlins without manual roller changing, which greatly saves setup time and labor costs. Supported by a PLC control system and automatic hydraulic cutting, the line ensures stable performance and long service life.

👉 Get a Free Quote Today

Main Features of the C Channel Purlin Machine

-

⚙️ Automatic size adjustment – Quick change between different C purlin sizes within seconds.

-

🧩 Heavy-duty frame design – Ensures long-term precision and stability during high-speed forming.

-

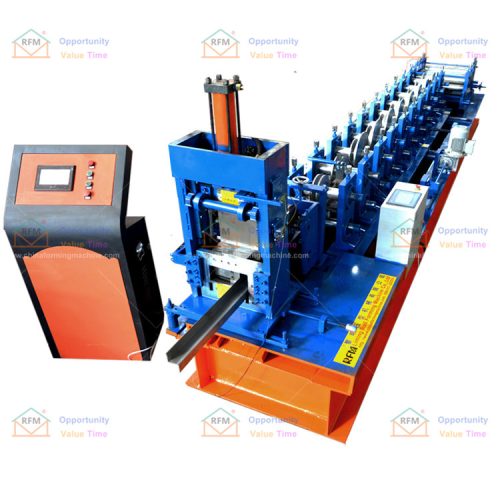

💡 PLC control system – Fully automatic control with touch screen and real-time production monitoring.

-

🧱 High precision rollers – Made of GCr15 with hard chrome coating for excellent durability.

-

🔧 Hydraulic cutting system – Guarantees smooth, burr-free cutting with accurate length control.

-

🔄 Optional punching system – Pre-punch holes for fast and easy installation at construction sites.

Technical Specifications

| Item | Description |

|---|---|

| Material | Galvanized steel, black steel |

| Thickness | 1.5–3.0 mm |

| Width | 100–350 mm |

| Forming speed | 15–25 m/min |

| Roller stations | 14–18 steps |

| Roller material | GCr15 with chrome coating |

| Drive system | Chain / Gear box |

| Cutting type | Hydraulic cutting |

| Control system | PLC with touch screen |

| Power | 15–22 kW |

Applications of C Channel Purlins

C channel purlins are widely used in various metal building and steel structure applications, including:

-

Industrial workshops

-

Warehouses and storage buildings

-

Roofing and wall support systems

-

Prefabricated and modular buildings

-

Solar mounting structures

These C purlins provide strong structural support while reducing the overall weight of the building, making them an economical and durable choice for construction projects.

Production Process

-

Decoiling – Automatic uncoiling of galvanized steel coil

-

Leveling & Feeding – Ensures straight, flat material entry

-

Forming – Step-by-step roll forming into C purlin shape

-

Cutting – Hydraulic cutting system with high precision

-

Output & Stacking – Finished C purlins automatically collected

(Recommended image: Production line with decoiler → forming → cutting section, file name: c-purlin-roll-forming-line.jpg, alt text: “Automatic C Channel Purlin Roll Forming Machine Line”)

Why Choose Our Purlin Roll Forming Line

-

29+ years of roll forming machine manufacturing experience

-

Customized profile design according to your drawing or standard size

-

On-site installation, training, and lifetime technical support

-

Exported to 100+ countries with CE & ISO certifications

-

Professional after-sales service and 24-hour online support

Video & Case Studies

Watch how our C channel purlin forming machine works in real production:

🎥 Video title: “Automatic C Purlin Roll Forming Line in Operation”

Project Example:

Our customer from Saudi Arabia ordered 3 sets of C and Z purlin lines to expand their steel structure production. After on-site testing, the machines achieved stable operation and excellent accuracy.

Related Machines

Get a Free Quote Now

Looking for a reliable C purlin roll forming machine for your steel structure business?

We offer full technical solutions — from design to production to installation.

📩 Contact us today!

Fill out the form below or email us at admin@chinaformingmachine.com — we’ll reply within 12 hours.