1. Water leakage at the overlap of the colored steel profiled plate.

Horizontal lap joints and vertical lap joints, leaks at the laps of colored steel profiled plates. If the color steel plate tile wave is too low or the amount of rain is not too large, it is easy to form a large area of water leakage, and it is not easy to notice the water leakage point Once it is formed, it is not easy to overhaul. More common in curved roofs. The main

reason is that the overlap between the two boards is not tight, the self-tapping screws are not filled, and the gap is formed.

2. Part of the roof ridge is leaking.

In light steel roof construction, water leakage caused by roof tiles is also a relatively common phenomenon. In the rainy season, especially when the amount of rain is large, the splash of rain water passes through the gap between the two colored steel profiled plates at the lower part of the ridge tile to form a large area of leakage. The main reason for water leakage at this part is: the crest at the ridge is too high, and the ridge cover cannot ensure waterproof; the longitudinal overlap does not put glue or silicone, forming a gap and leaking; the longitudinal overlap of the ridge cover is connected by rivets, thermal expansion and contraction strength If the rivet is not enough, the rivet will be broken, and water leakage will occur; no plug is laid between the roof slab and the roof panel, or the plug is placed in an irregular manner and falls off to form a leak. The solution is: make the roof ridge cover wider, and find a larger slope; lay glue or silicone at the lap; replace the staples; the plug should match the board type, and the glue or silicone should be placed up and down when laying the plug. In order to prevent the ridge tiles from leaking, it is advisable to increase the length of the ridge tiles in the construction, cut the edges of the tiles, and apply glue at the joints.

3. Part of roof gas building

The main reason for the leakage of this part is that there is no foam plug under the edge of the junction between the air building and the roof, and there is no mortar or silicone laid in the longitudinal overlap of the edge; the outer panel of the roof is not on the junction of the air building; the structure of the air building The openings of the pillars are not waterproofed; there are hidden dangers of water leakage in the gas building itself. The solution is: foam plugs should be laid before the edge installation, and the vertical laps must be set with cement or plugs to be fixed with suture nails; the roof panel must be installed before the air building is installed; Waterproof the openings and check the installation quality and waterproof performance of the gas building.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

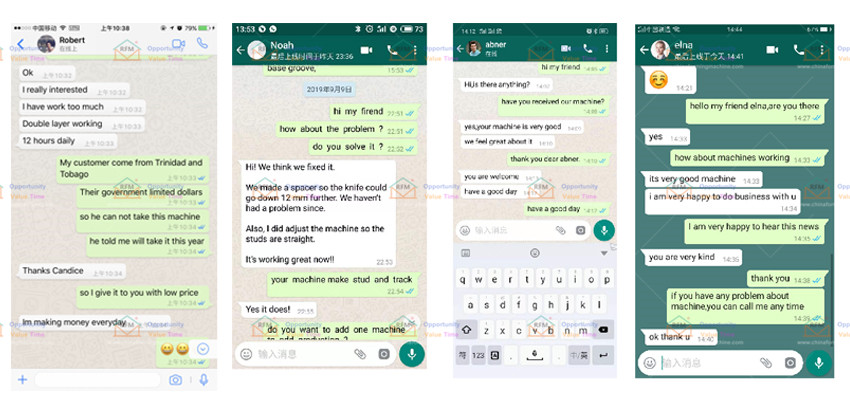

Customer Feedback