Steel Pipe Welding forming Machine supplier in china

Steel pipes can be divided into two categories according to production methods: seamless steel pipes and welded steel pipes. Welded steel pipes are referred to as welded pipes for short.

1. According to production methods, seamless steel pipes can be divided into: hot-rolled seamless pipes, cold-drawn pipes, precision steel pipes, hot-expanded pipes, cold-spinned pipes, and extruded pipes.

Seamless steel pipes are made of high-quality carbon steel or alloy steel, and are divided into hot-rolled and cold-rolled (drawn).

2. Welded steel pipes are divided into furnace welded pipes, electric resistance welded (resistance welded) pipes and automatic arc welded pipes due to their different welding processes.

Due to their different welding forms, they are divided into two types: straight seam welded pipe and spiral welded pipe. It is round welded pipe and special-shaped (square, flat, etc.) welded pipe.

Welded steel pipes are welded by butt seams or spiral seams of steel plates rolled into a tube shape. In terms of manufacturing methods, they are divided into welded steel pipes for low-pressure fluid transportation, spiral seam electric welded steel pipes, direct coil welded steel pipes, and electric welded pipes.

Seamless steel pipes can be used for liquid pressure pipes and gas pipes in various industries. Welded pipelines can be used for water pipelines, gas pipelines, heating pipelines, electrical pipelines, etc.

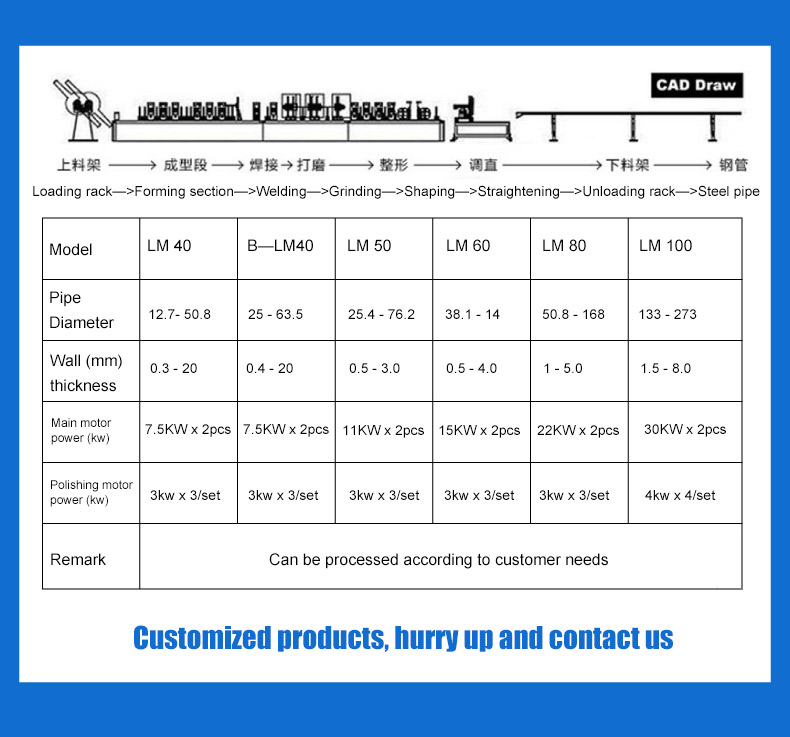

The steel pipe welding forming machine can pass the steel belt through the machine to form steel pipes of different sizes.

The pipes produced by our pipe welding forming machine: are welded tightly and have strong compression resistance. It is suitable for many kinds of industrial pipe production. For example, liquid transportation: milk, water transportation; automobile exhaust pipe; sanitary pipe, etc.