Pay attention to safety during the extensive use of floor support equipment

In the design of the high-rise steel structure of the floor board machine, the steel-concrete composite structure is often used. In the high-rise or high irregular high-rise buildings, the form of the core tube and the outer frame should not be selected for the sake of economy. The surrounding giant src columns should be selected, and the core is the structural system supporting the frame. More than half of such senior executives in my country are the former. Unfavorable against earthquakes. In the light steel industrial plant, when there is a large hanging load or moving load, you can consider abandoning the portal rigid frame and adopting a grid frame. In areas where the basic snow pressure is high, the roof curve should be conducive to falling snow, and areas with heavy rainfall are similarly considered. When the building permits, it is more economical to arrange supports in the frame than a simple frame with just connected nodes.

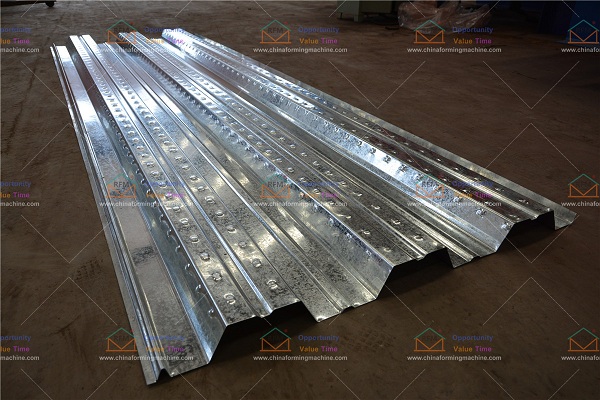

Notes on the use of floor support equipment:

Those who do not understand the structure and performance of the floor slab machine and the operating rules shall not start the machine. The design shall be carried out according to this requirement when manufacturing the mold to avoid machine tool accidents. It is strictly forbidden to work beyond the closed height, that is, a small distance from the bottom of the upper sliding box to all sides of the work 290㎜ requires that the height of the upper and lower molds after the mold is added, and the thickness of the upper and lower pads plus the thickness of the tile blank, not exceed 290㎜. Always pay attention to observe the height of the lubricating oil in the sliding box and the body on both sides. The equipment should be wiped frequently, kept clean, and no muddy water is allowed.