Operation method of debugging double-layer tile pressing machine

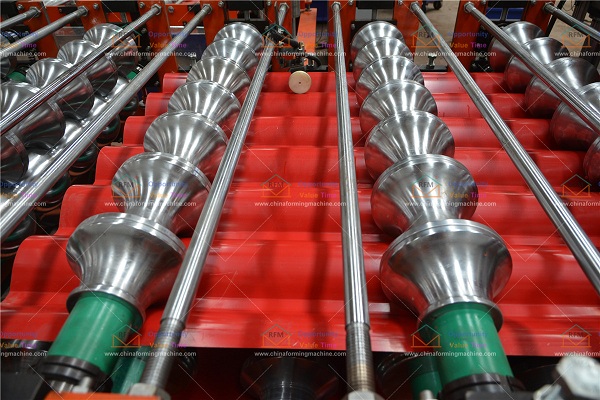

Adjust the gap of the double-layer tile machine, check if the lower shaft is on a straight line, find a straight line, the color steel tile press equipment and hydraulic pendulum shear equipment return speed is slow, the noise is large, put down The left and right sides of the shaft are adjusted to the thickness tolerance of the horizontal plastic core plate, and the material is also well controlled and utilized.

The height of the four corners of the front and back of the double-layer tile machine equipment from the large frame to the upper end of the bottom shaft is the same, which can ensure the reliable operation of the machine tool in the case of a failure of the connecting component.

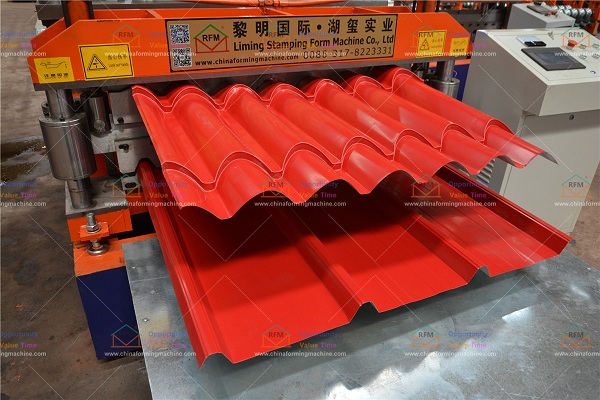

The double-layered tile machine has a reasonable cross-sectional shape, and the machined roll-formed profile is solemn and elegant, beautiful and novel, and has a flat appearance, uniform ripples, and high utilization. The transmission sleeves of the upper and lower die systems are respectively assembled with the rotating sleeve. Driven by a synchronously rotating worm gear drive, the transmission sleeve and the rotating sleeve are in a disengaged or meshed state by controlling the dial difference installed on the upper and lower transmission sleeves. The intensity is large, the production is highly automated, the cost is low, and it is durable.