Unique design of high-speed drywall roll forming machine—roller stand & roller

The arch-shaped structure is thicker and more stable, and has a more obvious advantage in handling special raw materials. Secondly, the archway adopts cast steel material, which has high stability in the production process and is easy to adjust, which greatly reduces the debugging time and enables customers to generate higher profits in the same time.

Whether the structure of the roller stand is reasonable is related to the stability of the machine, but other parts are also very important. Like this shaped wheel is also critical. It determines whether the profile is qualified. If the shaped wheel is not qualified, the profile produced is not Will pass. The mold wheel is the most used and stressed part of the production line. The raw materials of our company are purchased by CE and ISO certified state-owned steel mills, which solves the instability of different materials in batches of non-state-run small factories. The error of the machine guarantees that the machine is uninterrupted 24 hours, and it will create money when it is turned on.

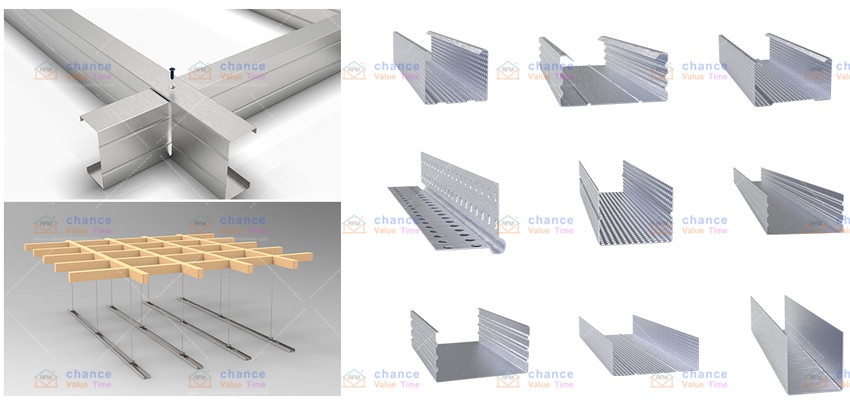

Application Range & Scene

Metal drywall roll forming machine Method & Customized Profile

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

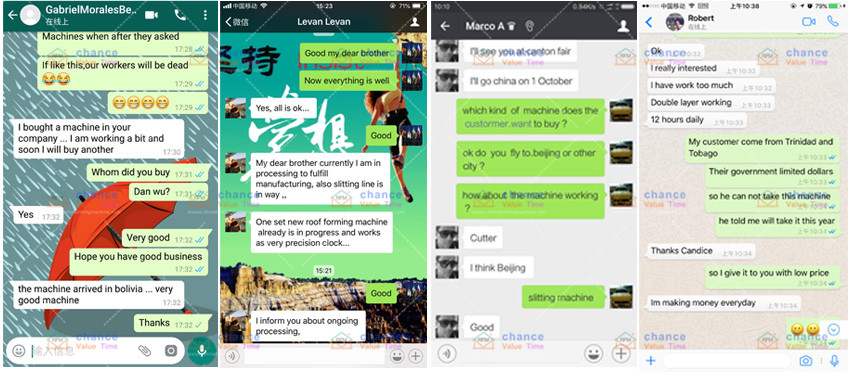

Customer Feedback