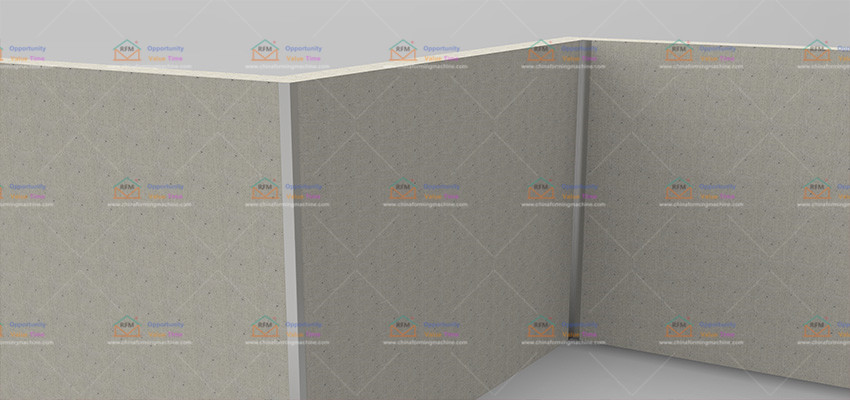

Installing peripheral corners for the ceiling is probably the easiest part of ceiling installation. The most important aspect of this installation is to keep the wall angle level and close to the wall, because this will determine the overall clarity of the ceiling.

It is important to install the angle steel firmly so that it can properly support the main slides and tees located around the ceiling.

The corner is the first step in the installation process of the ceiling grid. As professionals, we usually install corners before installing wires to prevent the wires from stabting the installer when we move around the room.

Liming provides a full set of fully automatic galvanized PPGI metal ceiling corner forming machine. The entire production line includes: automatic decoiler, forming equipment, hydraulic shearing equipment, PLC control equipment, automatic packaging equipment. The production speed can reach 30m / min.

A full set of fully automatic galvanized PPGI metal ceiling corner forming machine can save the labor cost of 2 workers. The machine speed is 30m / min, which is equivalent to 2 ordinary Metal ceiling corner forming machine . All electrical originals are imported from original brands, with a very low failure rate and super high cost performance!

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

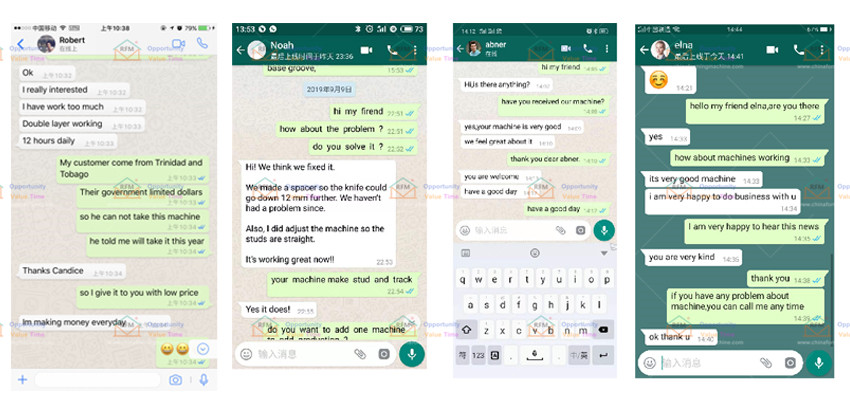

Customer Feedback