LM Roofing sheet rolling forming machine

we are engaged in offering a wide range of Roofing Sheet Roll Forming Machine. This product is manufactured using advanced techniques and with highly skilled professionals.

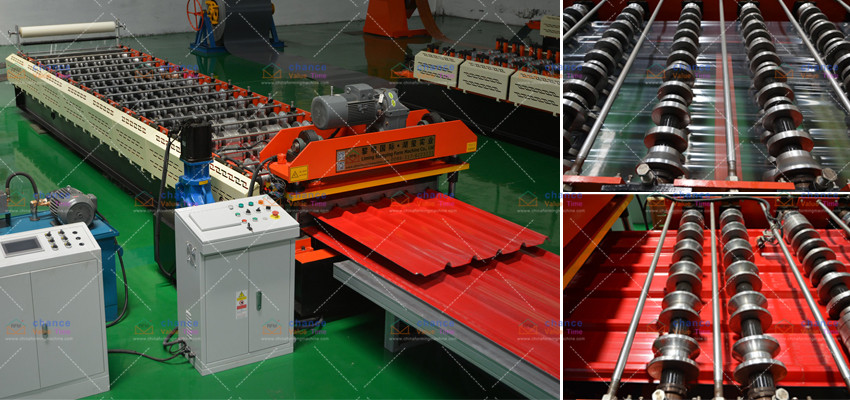

Roofing sheet roll forming machine consists of an automatic Decoiler feeding guide, roll forming unit, hydraulic cutter with PLC base control system. We are involved in offering a wide array of color sheet making machine that is manufactured using high grade raw material and the latest technology with the set universal standards.

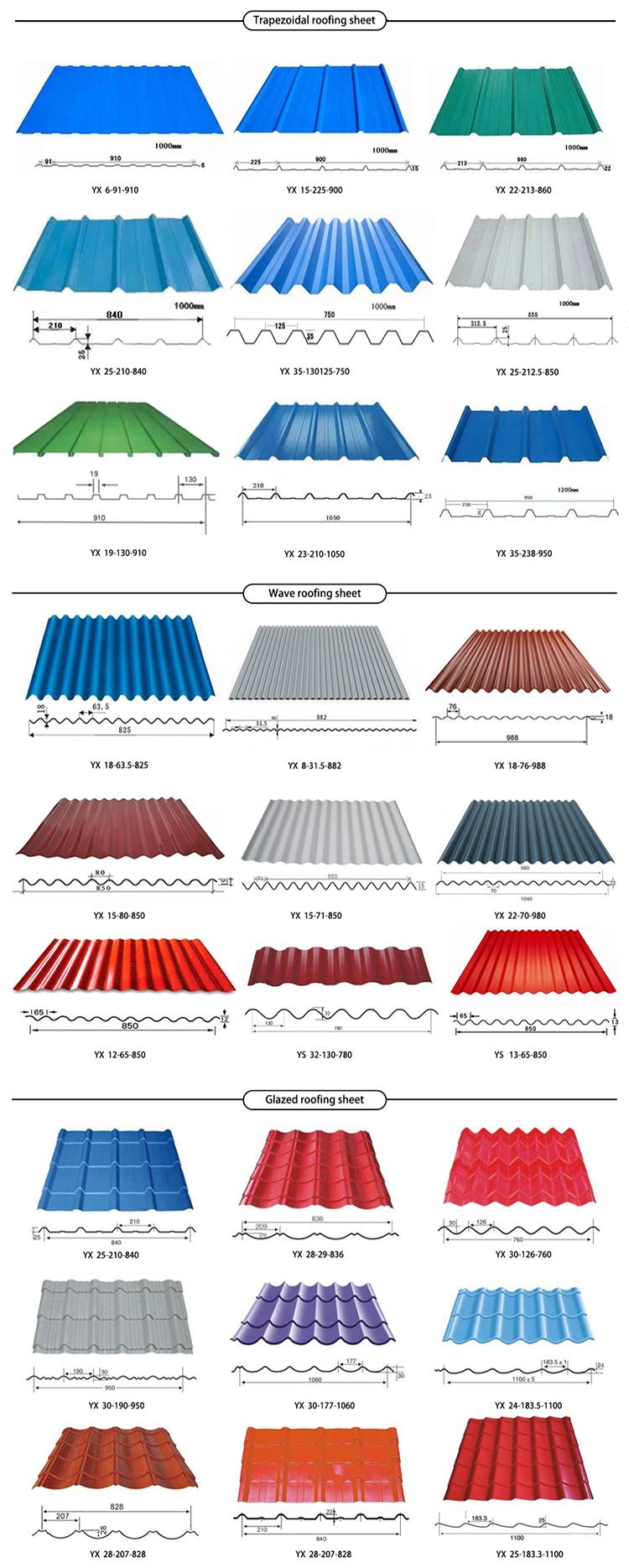

Popular design of R panel profile

Max ribs panel profile

TUFF-RIB PANEL profile

Box Rib PANEL profile.

AG metal PANEL profile.

Corrugated PANEL profile

STANDING SEAM METAL ROOFS profile

Batten style panel profile

GLAZED TILE profile

Q tile machines and others.

Machine elements and each part detail introduction:

Actually most of roofing tile rolling forming machines is composed by the following elements:

Decoiler: we have both Manual type or hydraulic types of 5 ton, 7 ton 10ton or others.

Main rolling forming machine: the roller station and detail elements will be designed according to customer requirements and drawing profiles;

Receiving table, we have manual one and the fully aromatic stacker.

How to design proper metal roofing sheets machines?

For all metal roofing sheet machines we customize according to customer requirements. First we need the customer drawing profile and then we can give the proper design plan.

Roofing sheet rolling forming machine using

The finished products, color steel roofing sheets are suitable for industrial and civil buildings, warehouses, special buildings, roofs, walls and interior and exterior wall decorations of large-span steel structure houses. It has light weight, high strength, rich color, convenient and quick construction, earthquake resistance, fire protection, rain protection, and longevity. Long, maintenance-free and other characteristics have been widely promoted and applied.