Liming custom stainless steel pipe welding machine

Factory Price Stainless Steel/Ms pipe welding machine Making SS Square/Round Pipes

Stainless Steel pipe welding machine is designed to produce welded round pipes, with the characters of advance, steady, perfect and maturity etc. The mill line is newly designed based on practical producing and acquiring the advantages of equipment home and abroad,which is also convenient in operation and maintenance.

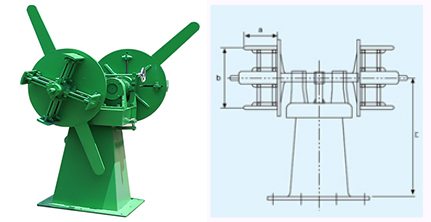

pipe welding machine Part 1: Un-coiler

Manual operation with adjustable brake

Two sides, coil adapting cone with loading weight: ≤1T per side

pipe welding machine Part 2: Forming Section

Feeding equipment: 2 roller guide apparatus

3 break down+3 by-pass+3 fin pass

Horizontal Stands shaft dia.: 40mm

Vertical Stands shaft dia.: 25mm

Arrangement:

3-3-1-4 or 4-4-1-4 or customized

Horizontal Stand:

Needle Bearings in operation side Horizontal Stand,it is easy to change and adjust roll sets, will take roughly 40 minutes to change full set roll sets

pipe welding machine Part 3: Welding Section

Welding Torch: Single

2 sets squeezing Rollers

Advantage for UT Welder:

(1) Dust proof, to protect the machine

(2) Pipe Welding quality will be much better than TIG Welder;

(3) It saves about 30% Argon Gas Consumption;

(4) It will improve production speed about 30%

pipe welding machine Part 4: Seam Polishing Section

Totally enclosed automatic Grinding head

In automatically pressing down polishing system by electric motor, one engineer can operate five set tube mill. And it can make grinding section cleaner and grinding more stable.Totally Enclosed box with grinding head can make grinding section cleaner.

Part 5: Sizing &Turk-Head

Straightening and sizing for pipes

To reset the roundness of pipes

Turk Head: 2 Units

Part 6: Cutting Section

Friction Saw Cutter

Auto-mechanical

Operational panel

Cutting length: 4-10m

Metal Saw Cutter

Less burr in the end of the pipe

Part 7: Run-out table

IncludedL: 6m

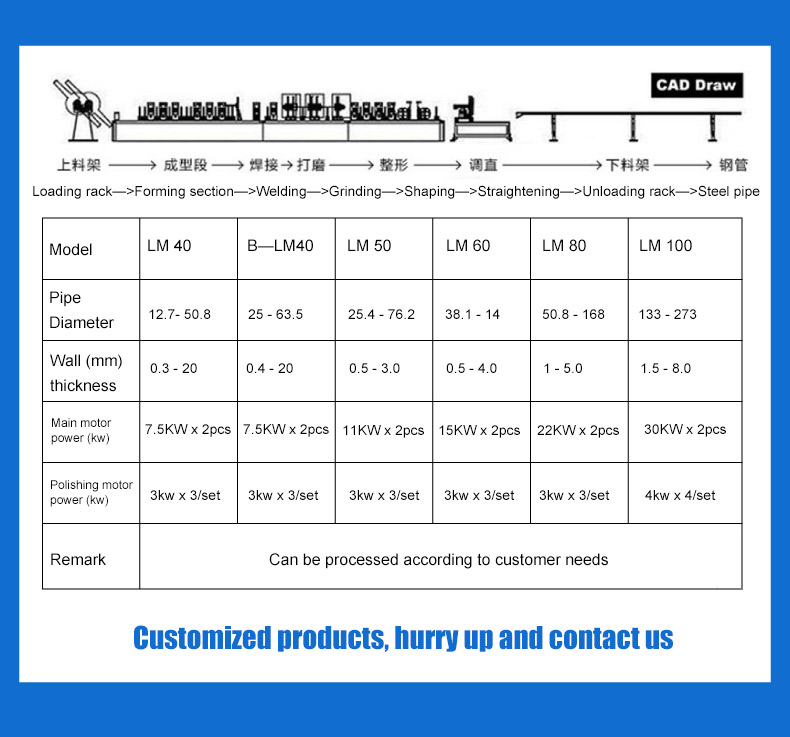

Pipe welding machine More specifications

Model |

Pipe Diameter |

Pipe Thickness |

Capacity |

Major Power |

|

LM40

|

6-31.8mm

|

0.2-1.2mm

|

1-20m/min

|

5.5KW

|

|

LM40

|

8-50.8mm

|

0.2-1.5mm

|

1-15m/min

|

7.5KW

|

|

LM40

|

12.7-63.5mm

|

0.3-2.0mm

|

1-10m/min

|

11KW

|

|

LM50

|

25.4-76.2mm

|

0.4-2.5mm

|

1-7m/min

|

15KW

|

|

LM60

|

38.1-114mm

|

0.5-3.0mm

|

1-5m/min

|

18.5KW

|

|

LM80

|

76.2-168mm

|

1.0-4.0mm

|

1-3m/min

|

22KW

|

|

LM100

|

159-325mm

|

1.0-6.0mm

|

1-15m/min

|

30KW

|

1. who are we?

Liming Stamping Form Machine Co.,Ltd, founded in 1996, As a manufacturers and exporters for 26 years. We have a high-quality team, 15 persons of foreign service team;Professional Engineer with 25 years experience of adjusting machines;Professional design term with 26 years design experience.

2. how can we guarantee quality?

In order to ensure the processing accuracy of the machine and ensure the stability of the machine’s operation, the accessories on the pipe making machine are independently processed and produced. We have a variety of processing equipment,such as Horizontal machining center,Vertical Machining Center,CNC lathe,Coordinate Boring Machine.

Our products have been widely used in multiple well-known stainless steel enterprises, and won wide recognition and good reputation.

3.what can you buy from us?

As one of the leading enterprises in stainless steel tube mill industry, Liming Stamping Form Machine Co.,Ltd has been specializing in manufacturing Pipe Making Machine, Rollers(Toolings), Pipe Polishing Machine, Pipe Embossing Machine and Slitting Machine in last 20 years.

4. why should you buy from us not from other suppliers?

1.Have an excellent service team;

2.Customized service for client’s requiement;

3.High quality, competive price.

5. what services can we provide?

Offer Services

We can provide pre-sales consultant& On-purchase for everyday

1.Reply Time: Within 1 hours(Not 24 hours)

2.Provide Tube Mill Machine relevant product information

3.Give you technical good suggestion

After Service–Provide service 24 hours*7 days per week

1.Test the tube mill machine before shipment

2.Provide installation service, according to customer needs;

3.Training service: teach customers how to use the machine

4 Assistance service: ①Improve pipe quality;②Improve production capacity;③Reduce production cost;④Reduce warehouse storage