Liming Cable tray equipment

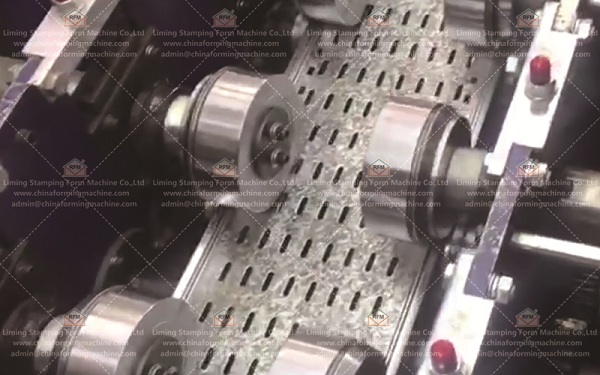

The cable bridge equipment is a special equipment for cold-bending profile forming, which is a non-standard equipment and is designed and customized according to the user’s product requirements. This equipment first installs the raw materials on the unwinding rack, leveling into the main machine, and then gradually deformed by the main mold and some auxiliary forming devices on the main machine to form a desired geometric shape, and then enter the straightening device to eliminate the internal stress , According to the straightness of the product, and then cut by the cutting machine to meet the user’s requirements for the product. After that, it is manually moved away from the receiving table.

The cable tray equipment is produced by rolling primary color steel strip or galvanized steel strip. The production requires linearity of the bottom edge. In actual production, many companies do not pay attention to it, only the quantity, and there is no timely adjustment when linear bending occurs. When using cable bridges, the staff of the factory will notice the use of arched ladder edges as soon as they are not aware, that is, both sides of the bridge are grounded, and the middle is suspended. Therefore, inexperienced manufacturers often send out the goods and objections also appear. In order to avoid the above situation, it is necessary to purchase the equipment of manufacturers with relatively long production and production time.

The bridge ladder for our company is formed by the ladder edge forming unit at one time. It has beautiful shape, strong rigidity and stability. The ellipse connection holes are directly machined at both ends of the ladder edge. There are 3 connection holes at each end of H125mm and below , H125mm or more with 6 connection holes at each end. The length of the ladder side is generally 2m, and the length of the long-span ladder side is 6m. It can also be processed into 4m, 8m or other sizes according to user requirements. It is suitable for making large-span cable trays.

Cable tray equipment is suitable for the production of various types of cable tray profiles. The raw material coil material used in this unit can be ordinary cold-rolled sheet, galvanized sheet, aluminized zinc plate, stainless steel sheet, aluminum sheet and high strength (300~550Mpa yield strength) steel sheet. The unit is formed, the process is accurate, and the pipeline operation can meet the needs of manufacturers of various production efficiency and scale for finished products.