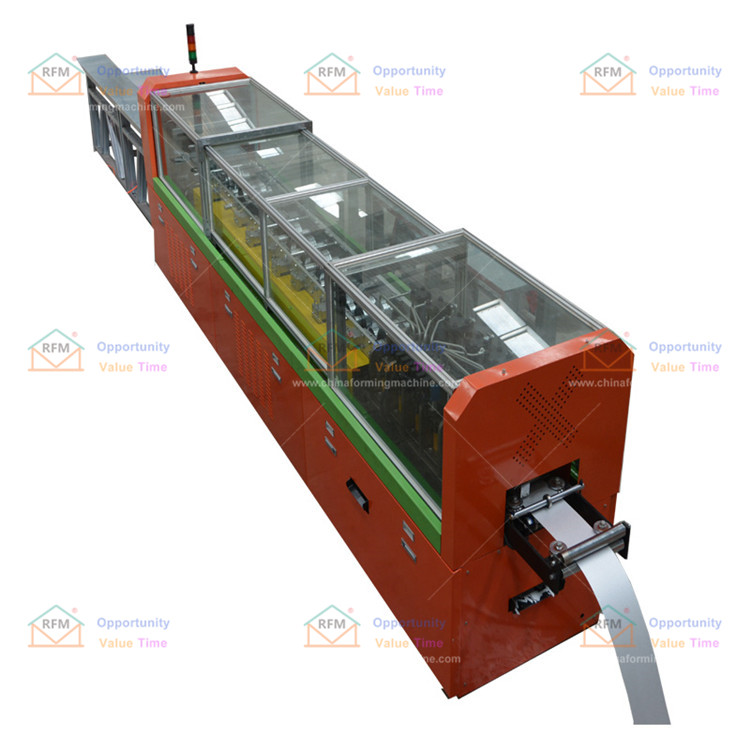

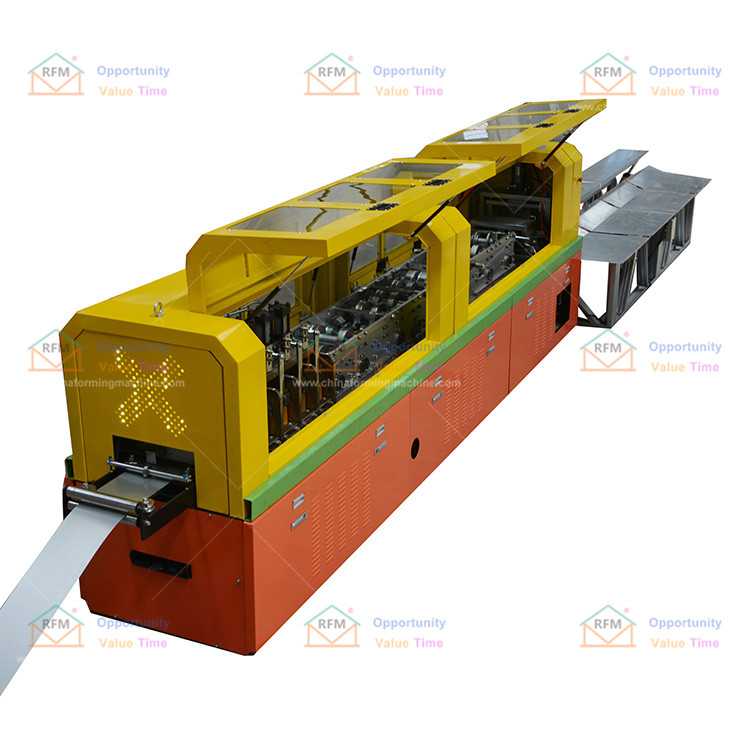

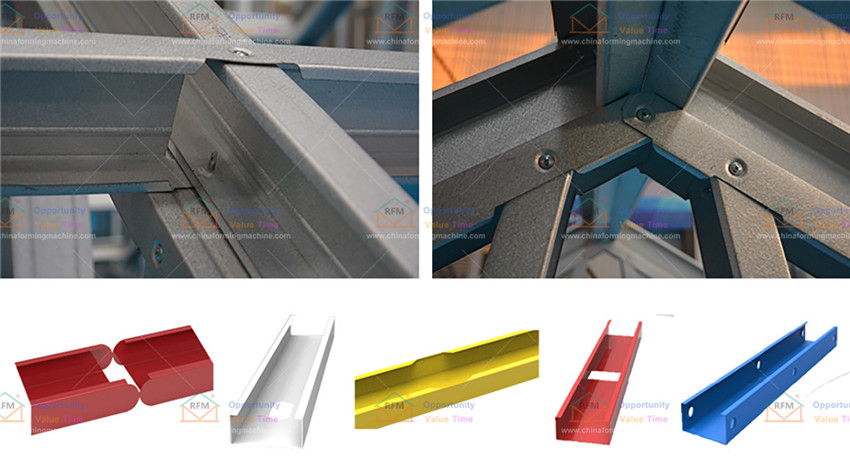

light gauge steel machine materials and finished products

The light gauge steel machine consists of the following components: decoiler, leveling machine, roll forming machine, shearing system, punching unit and receiving table.

Brief introduction of each component:

1. Uncoiler

Purpose: used to support the steel coil and untie it by a turntable. Passive decoiler drawn by roll forming system

Load capacity: 1.5T

Uncoiling width: 300mm

Inner diameter: 450-550mm

2. Feeding and leveling

This part will flatten the steel coil to ensure it is clean and straight.

3. Main forming machine

Gear transmission mode, roller material is GCr12MoV. The shaft will use 45# steel with a tempered diameter of 50mm. Usually, we will use 12 roller stations to process the final version.

4. Stamping logo and cutting system.

Stamping the logo and cutting will be done in one unit. For cutting, in order to increase the working speed, we will use the servo non-stop system.

Power: hydraulic power

Frame: Strut Gear and Pinion System

Travel switch: non-contact photoelectric switch

5. Electrical control system

1. Using Taiwan Delta PLC, frequency converter, touch screen, to ensure high speed, stability, accuracy, and long life.

2. Other electronic components are Taiwan Delta.

3. Equipped with movable switch, air circuit breaker, radiator, transformer and leakage protector, easy to operate and safe.

installation:

Light steel can be used for the construction of light steel houses and the installation of house ceilings and gypsum boards.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

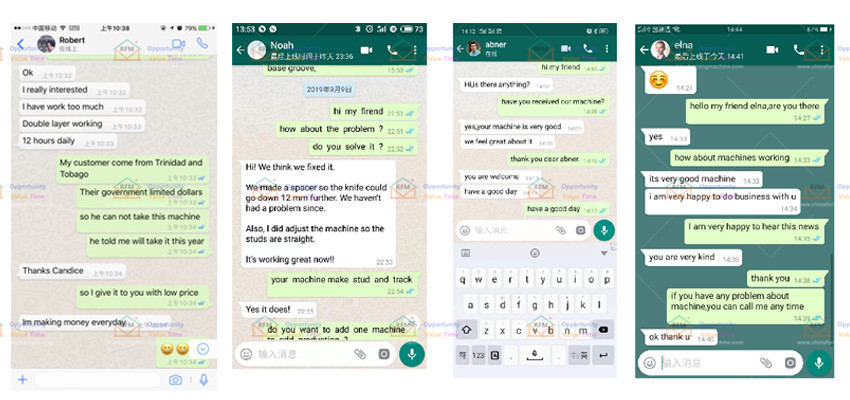

Customer Feedback