A customer from the United States wanted to purchase our light gauges steel forming machine to build a low-rise villa, but he did not know the machine very well. He did not know how long it

would take to pay back the cost, so I made value for him Accounting.

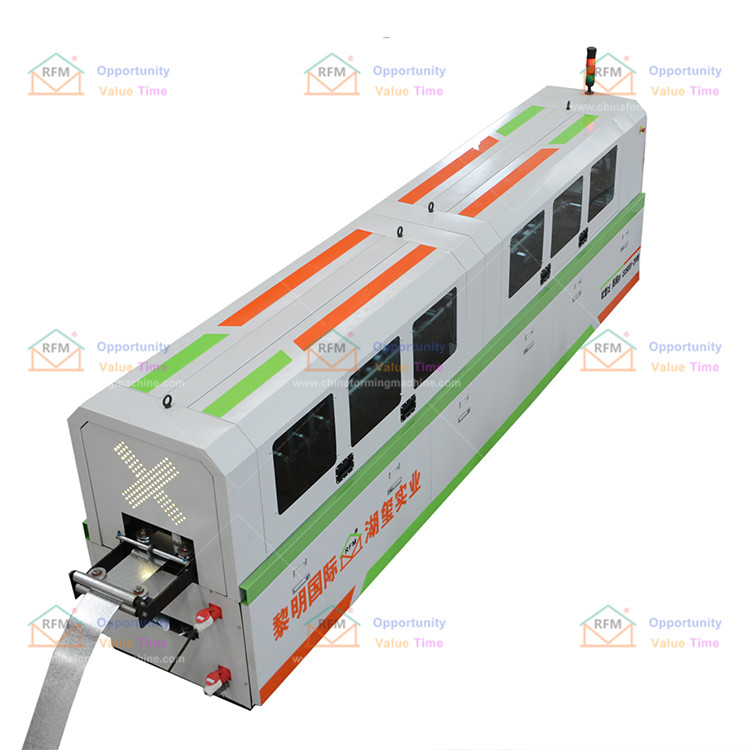

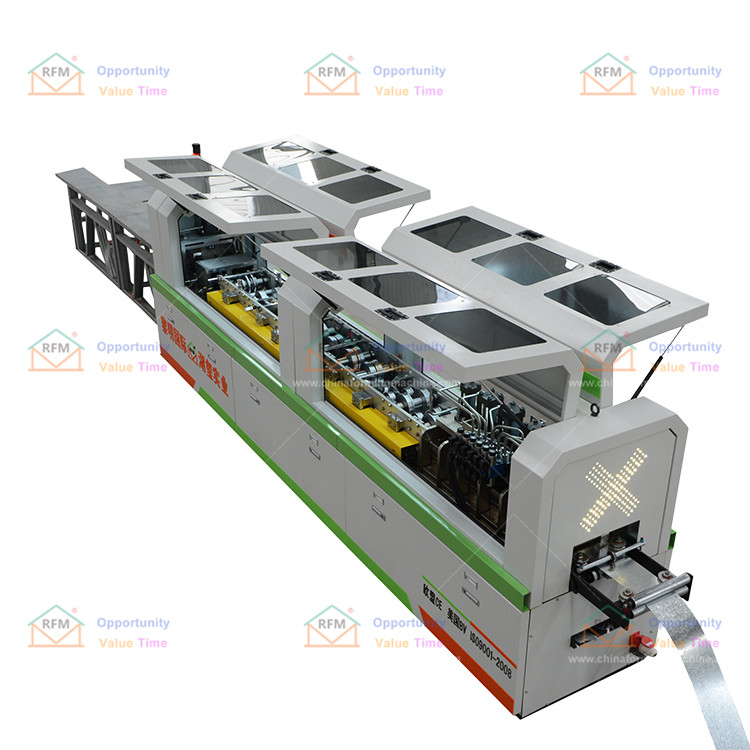

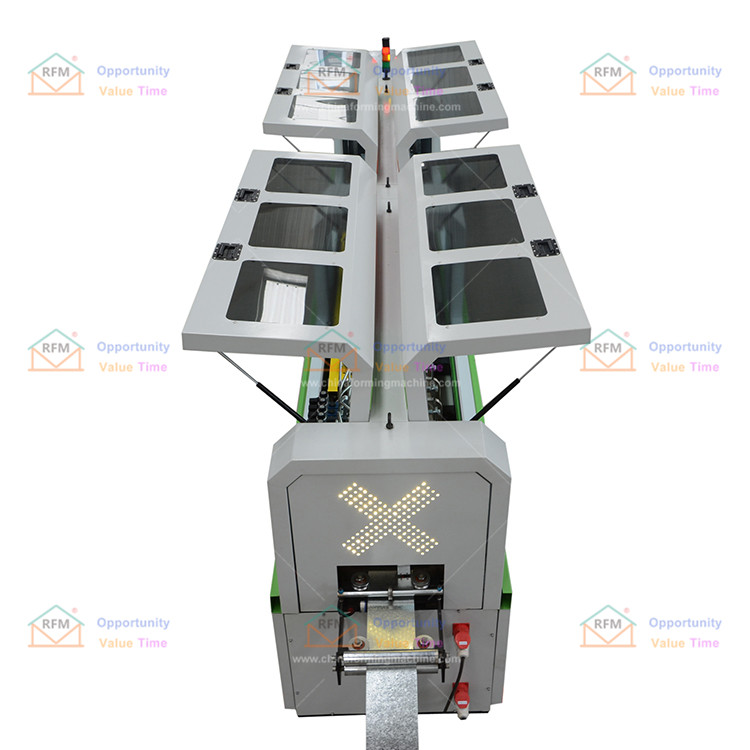

Labor costs in the United States are very high. And our light gauges steel forming machine has a very high degree of automation. All data is controlled by a computer. The machine can run by itself, and the machine is equipped with a fully automatic receiving table and fully automatic uncoiling. For the whole process of forming and splicing, completely 0 manual operation is realized. Compared with ordinary machines, it saves at least 6 manpower, one worker is 160$ per day to calculate. In this way, less than 3 months, the saved labor cost can be used to buy a machine, and our The machine can be used for 10 or 20 years. It is only a labor cost. After 3 months, compared with competitors, the husband is a net income.

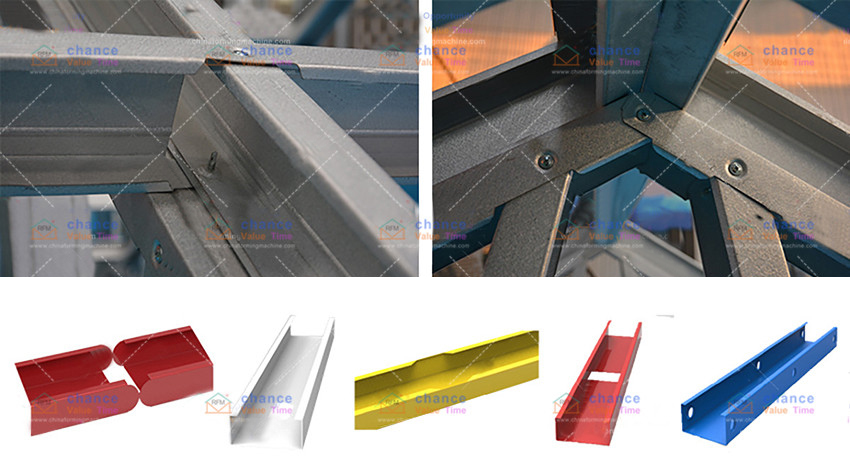

And not only can you save labor costs, our machine is also very fast. It can produce 3-4 tons of profiles in a day, and one square meter needs 30kg. According to our machine can produce 3 tons a day, so a 3-layer For a house of 120 square meters, 3*120*30/1000/3=3.6, it only takes less than 4 days, and our machine can produce a 3-story 120 square meter villa without labor. And such a villa is worth about 180,000 US dollars in the United States. It only takes less than 4 days for our machines to produce all the profiles of the villa worth two machines. So the return cycle is very fast.

After value accounting, the customer understood the return cycle, he was very satisfied, and we reached a pleasant cooperation.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

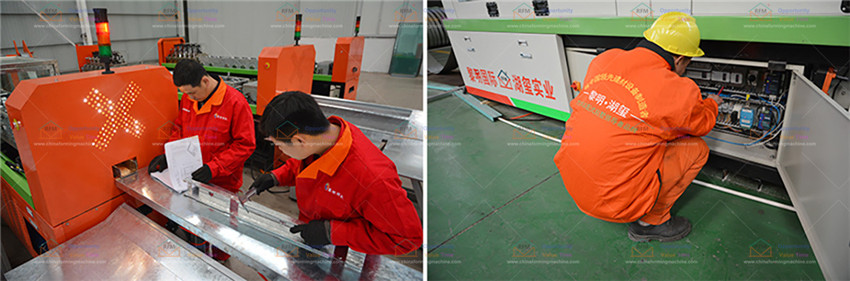

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

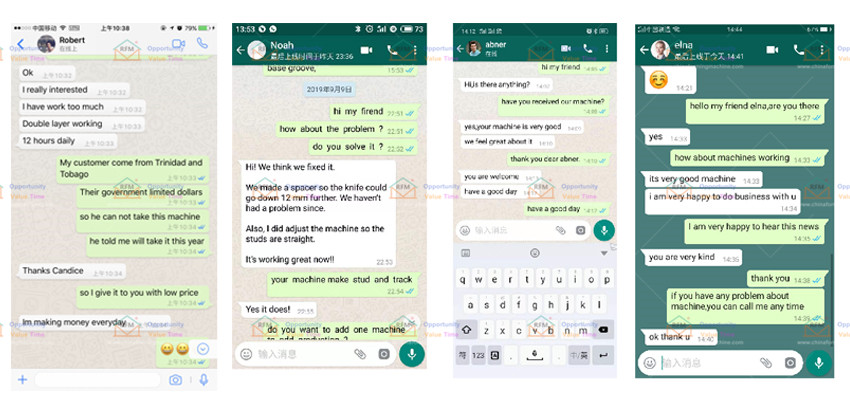

Customer Feedback