An American supplier specializing in the production of keel steel contacted us and wanted a keel forming equipment that could meet their high-precision production requirements.

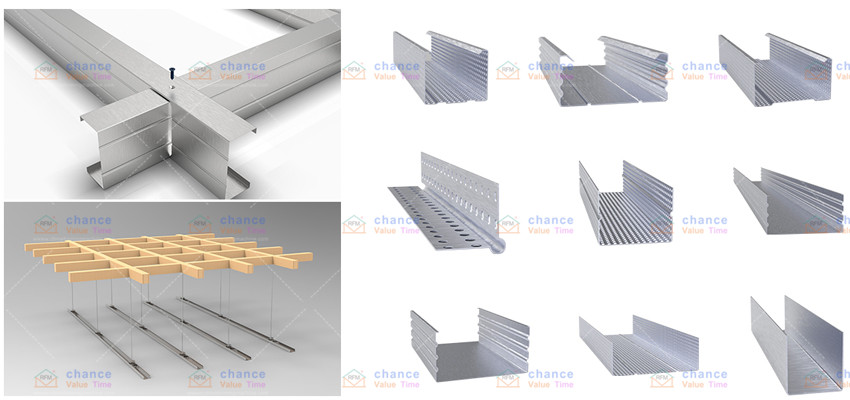

During the communication, I found that this American customer is very interested in our high-precision L-shaped keel forming equipment, so we recommended this L-shaped angle steel light steel keel forming machine for steel structure connection in the construction industry. Since the L-angle profile has a decorative effect, for the profile, it is necessary to have no burrs on the cutting surface and no scratches on the surface, which requires stricter production accuracy. Liming Company, which has 24 years of production experience, adopts CNC precision processing for all equipment to ensure the precision requirements of production. After the machine is manufactured, we will use raw materials to test the machine and adjust the structure of the machine in time to ensure the integrity of the final product and solve the problem of unsightly surface of the profile. The raw materials for the wheels, large frames and other accessories we use to manufacture are all purchased from large state-owned steel mills. The raw material is high-quality steel. These companies have international qualifications and have gone through various inspections, so there is no need to worry about the quality of raw materials. We use the best raw materials to produce the best machines. After the machine is formed, it will be checked layer by layer to ensure that the machine is in good condition after it is handed over to the customer. In the communication process, the customer hopes to use higher quality equipment, which can ensure that his production line can operate for a long time. Therefore, we explained to customers that for customers with special needs, we can upgrade the configuration and choose components from internationally renowned brands such as Siemens and Mitsubishi to improve the quality of the machine and fully meet the actual needs of customers. After listening to us, the customer in the United States will accept it and are very satisfied, and immediately discuss with us the specific details of the next cooperation.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

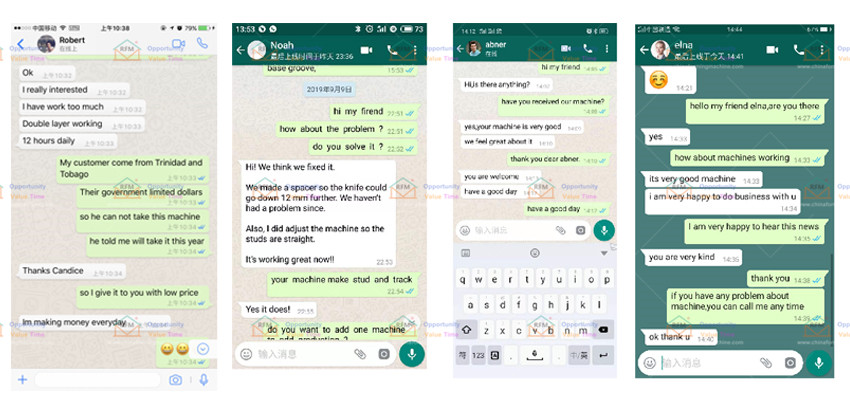

Customer Feedback